Method for extracting and purifying procyanidine from waste grape seeds

A purification method and proanthocyanidin technology, applied in the direction of organic chemistry and the like, can solve problems such as the ineffective utilization of resources, and achieve the effects of low cost, good production safety and good yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

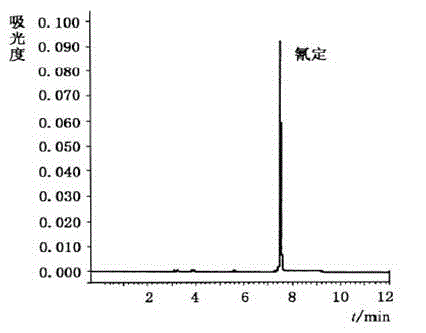

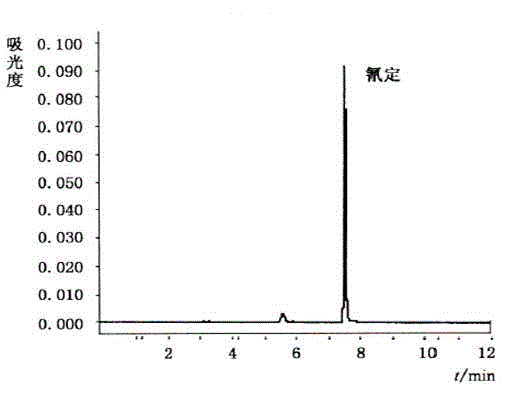

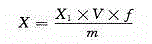

Image

Examples

Embodiment 1

[0021] 1. After crushing the grape seeds, take 30g of grape seed powder and add 9 times the volume of 50% ethanol: 4% citric acid = 3:1 solvent, extract in a water bath at 40°C for 60 minutes, extract once, and cool and filter after extraction.

[0022] 2. Rotary steam at 40-50°C to the value of 1g of crude drug, ethanol precipitation with 95% ethanol, and refrigerate at 4°C for more than 12 hours;

[0023] 3. After filtering the alcohol precipitation solution, concentrate it to 1 / 8 of the filtrate, add 4 times of distilled water and mix evenly;

[0024] 4. Extract twice with n-butanol respectively, combine the extracts, and wash the extracts twice with saturated saline;

[0025] 5. Concentrate and dry the extract by rotation at 40-70° C. to obtain about 1.43 g of grape seed proanthocyanidin powder.

Embodiment 2

[0027] 1. After pulverizing the grape seeds, take 30g of grape seed powder and add 8 times the volume of 50% ethanol: 4% citric acid = 4:1 solvent, reflux extraction in a water bath at 50°C for 50min, extract once, and cool and filter after extraction.

[0028] 2. Rotary steam at 40-50°C to 1.5g crude drug value, ethanol precipitation with 95% ethanol, and refrigerate at 4°C for more than 12 hours;

[0029] 3. After filtering the alcohol precipitation solution, concentrate it to 1 / 4 of the filtrate, add 4 times of distilled water and mix evenly;

[0030] 4. Extract twice with n-butanol respectively, combine the extracts, and wash the extracts twice with saturated saline;

[0031] 5. Concentrate and dry the extract by rotating at 40-70° C. to obtain about 1.61 g of grape seed proanthocyanidin powder.

Embodiment 3

[0033] 1. After crushing the grape seeds, take 30g of grape seed powder and add 7 times the volume of 50% ethanol: 4% citric acid = 5:1 solvent, reflux extraction in a water bath at 60°C for 60min, extract once, and cool and filter after extraction.

[0034] 2. Rotary steam at 40-50°C to 1.5g crude drug value, ethanol precipitation with 95% ethanol, and refrigerate at 4°C for more than 12 hours;

[0035] 3. After filtering the alcohol precipitation solution, concentrate it to 1 / 8 of the filtrate, add 4 times of distilled water and mix evenly;

[0036] 4. Extract twice with n-butanol respectively, combine the extracts, and wash the extracts twice with saturated saline;

[0037] 5. Concentrate and dry the extract by rotating at 40-70° C. to obtain about 1.82 g of grape seed proanthocyanidin powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com