Preparation method of nano silver particle loaded antimicrobial titanium dioxide coating

A technology of nano-silver particles and titanium dioxide is applied in the field of surface modification of biomedical materials, which can solve the problems of limited application of antibiotic-resistant strains, and achieve the effect of ensuring continuous silver ion release, good inhibition and good binding force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

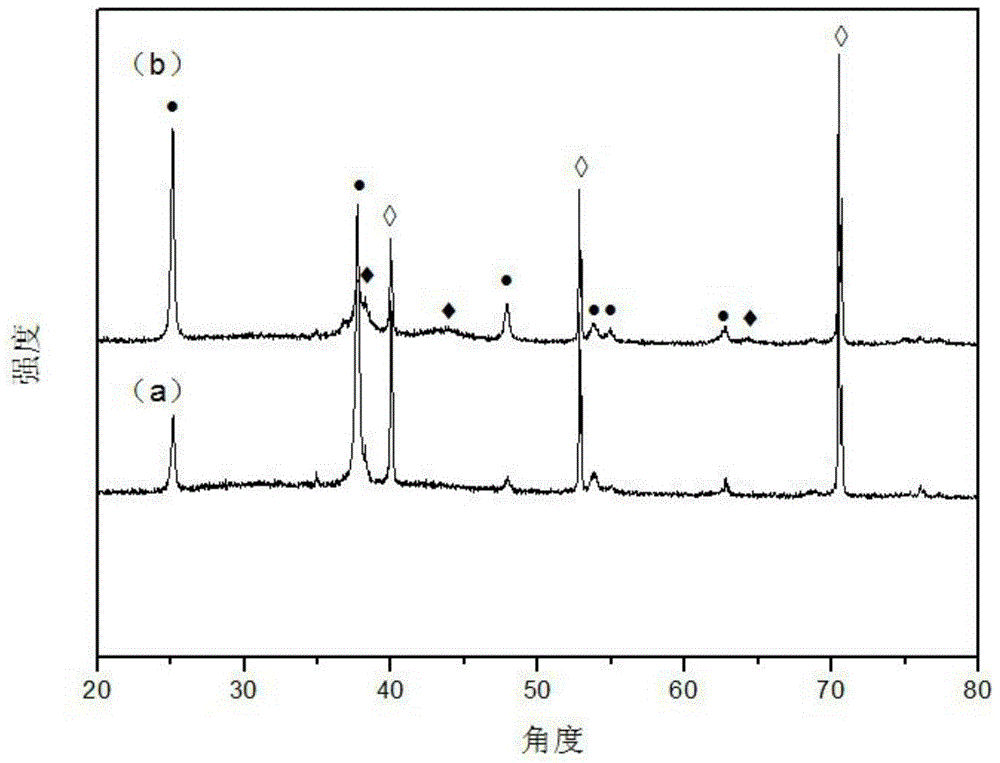

[0021] 1) Put 10×14×1mm 3 The pure titanium sheet is polished by 400#, 1200#, 2500# water sandpaper in turn until the surface is smooth without obvious defects. The polished samples were cleaned in de-ethanol and deionized water for 5 min, and dried at room temperature.

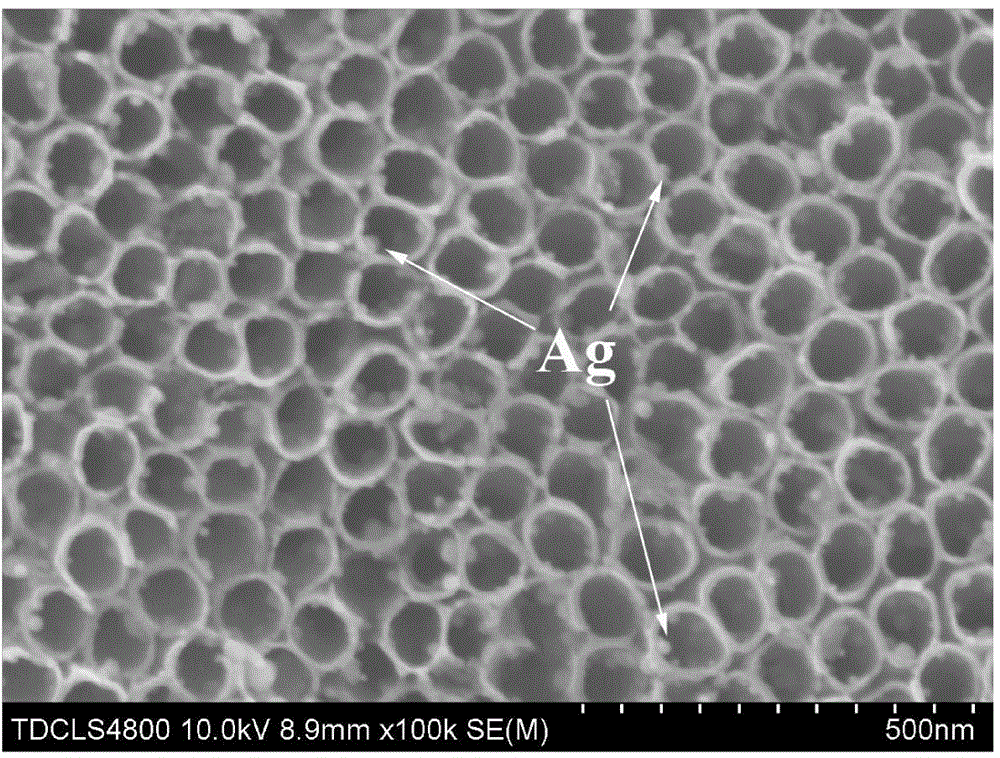

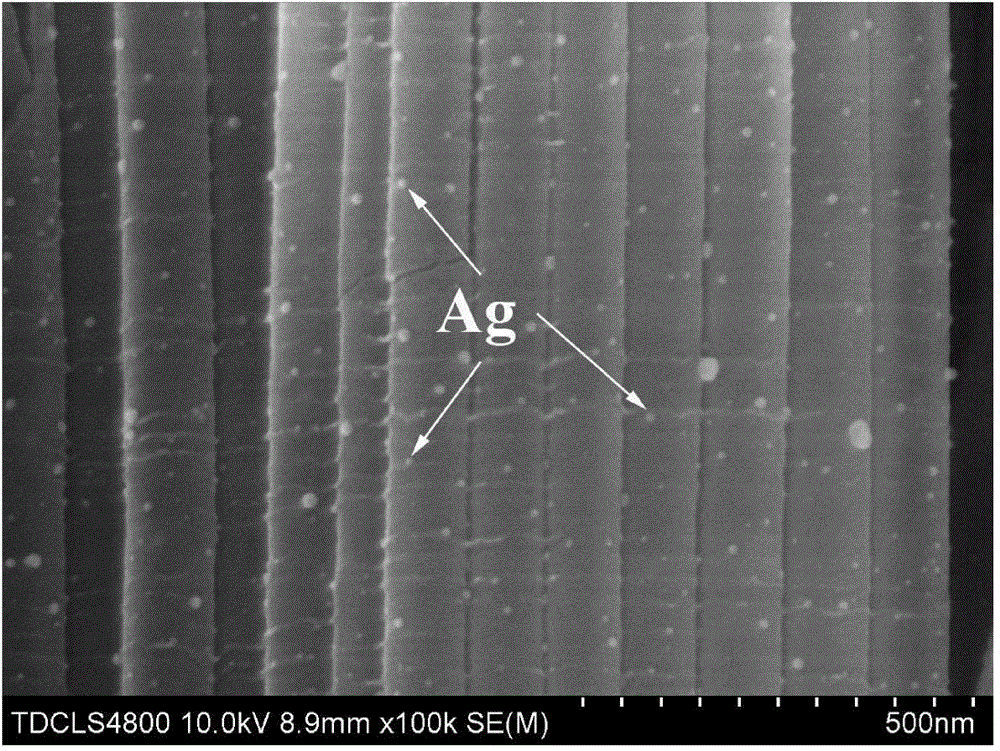

[0022] 2) Use ethylene glycol-water (1:1vol.%) to add 0.14MNH4F system as the electrolyte, set the anode voltage to 40V, and the oxidation time to 3h to prepare self-assembled TiO2 nanotubes. The oxidized sample was ultrasonically cleaned in absolute ethanol solution, then washed in deionized water and air-dried naturally.

[0023] 3) The dried sample is heat treated in a box furnace with a heating rate of 4°C / min, a holding temperature of 450°C, and a holding time of 1 hour.

[0024] 4) Add PVP to the mixed solution of water / ethylene glycol (volume ratio 1:1), stir for about 5 minutes to mix well, and then add sodium borohydride during the stirring process. After 1-2min, silver nitrate was added. The con...

Embodiment 2

[0026] 1) Put 10×14×1mm 3 The pure titanium sheet is polished by 400#, 1200#, 2500# water sandpaper in turn until the surface is smooth without obvious defects. The polished samples were cleaned in de-ethanol and deionized water for 5 min, and dried at room temperature.

[0027]2) Use ethylene glycol-water (1:1vol.%) to add 0.14MNH4F system as the electrolyte, set the anode voltage to 20V, and the oxidation time to 3h to prepare self-assembled TiO2 nanotubes. The oxidized sample was ultrasonically cleaned in absolute ethanol solution, then washed in deionized water and air-dried naturally.

[0028] 3) The dried sample is heat treated in a box furnace with a heating rate of 4°C / min, a holding temperature of 450°C, and a holding time of 1 hour.

[0029] 4) Add PVP to the mixed solution of water / ethylene glycol (volume ratio 1:1), stir for about 5 minutes to mix well, and then add sodium borohydride during the stirring process. After 1-2min, silver nitrate was added. The conc...

Embodiment 3

[0031] 1) Put 10×14×1mm 3 The pure titanium sheet is polished by 400#, 1200#, 2500# water sandpaper in turn until the surface is smooth without obvious defects. The polished samples were cleaned in de-ethanol and deionized water for 5 min, and dried at room temperature.

[0032] 2) Use ethylene glycol-water (1:1vol.%) to add 0.14MNH4F system as the electrolyte, set the anode voltage to 60V, and the oxidation time to 3h to prepare self-assembled TiO2 nanotubes. The oxidized sample was ultrasonically cleaned in absolute ethanol solution, then washed in deionized water and air-dried naturally.

[0033] 3) The dried sample is heat treated in a box furnace with a heating rate of 4°C / min, a holding temperature of 450°C, and a holding time of 1 hour.

[0034] 4) Add PVP to the mixed solution of water / ethylene glycol (volume ratio 1:1), stir for about 5 minutes to mix well, and then add sodium borohydride during the stirring process. After 1-2min, silver nitrate was added. The con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com