Corrugated medium produced from waste paper papermaking sludge as well as production method of corrugated medium

A corrugated base paper and waste paper papermaking technology, which is applied in papermaking, textiles, papermaking, paper, etc., can solve the problems of inefficient use of sludge resources and high sludge disposal costs, reduce the consumption of waste paper raw materials, and improve water filtration performance , the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] In the process of producing corrugated base paper with imported American waste paper as raw material, add primary sludge with 0.5% pulp fiber mass; biochemical sludge with 1% pulp fiber mass; 1% pulp fiber mass in the mixed stock tank before the paper machine cationic starch; cationic polyacrylamide with pulp fiber quality 0.01%; mixed evenly; online papermaking, pre-drying, surface sizing with surface sizing starch, and post-drying; surface sizing starch is corn starch, and its dosage is primary precipitation 1 times the total amount of sludge and biochemical sludge. The primary sludge is the sludge produced in the primary sedimentation tank during the sewage treatment process, and the biochemical sludge is the system residual sludge settled in the secondary sedimentation tank and advanced treatment after aerobic treatment in the sewage treatment process. The main process conditions of corrugated base papermaking: the concentration of paper material on the net is 0.5wt...

Embodiment 2

[0025] In the process of producing corrugated base paper with domestic waste paper as raw material, add primary sludge with 2% pulp fiber mass; biochemical sludge with 0.5% pulp fiber mass; 0.1% pulp fiber mass Cationic starch; cationic polyacrylamide with pulp fiber quality of 0.08%; mixed evenly; online papermaking, pre-drying, surface sizing with surface sizing starch, and post-drying; surface sizing starch is wood department starch, and its dosage is primary sedimentation 0.2 times the total amount of sludge and biochemical sludge. The primary sludge is the sludge produced in the primary sedimentation tank during the sewage treatment process, and the biochemical sludge is the system residual sludge settled in the secondary sedimentation tank and advanced treatment after aerobic treatment in the sewage treatment process. The main process conditions of corrugated base papermaking: the concentration of paper material on the net is 0.5wt% ~ 0.7wt%, the dryness of sizing on the...

Embodiment 3

[0027] In the process of producing corrugated base paper with domestic and imported American mixed waste paper as raw materials, primary sludge with 1.5% pulp fiber mass; biochemical sludge with 0.7% pulp fiber mass; pulp fiber mass Cationic starch with a mass of 0.5%; cationic polyacrylamide with a pulp fiber mass of 0.04%; mixed evenly; online papermaking, pre-drying, surface sizing with surface sizing starch, and post-drying; surface sizing starch is corn starch, and its dosage It is 0.5 times of the total amount of primary sludge and biochemical sludge. The primary sludge is the sludge produced in the primary sedimentation tank during the sewage treatment process, and the biochemical sludge is the system residual sludge settled in the secondary sedimentation tank and advanced treatment after aerobic treatment in the sewage treatment process. The main process conditions of corrugated base papermaking: the concentration of paper material on the net is 0.5wt% ~ 0.7wt%, the dr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tightness | aaaaa | aaaaa |

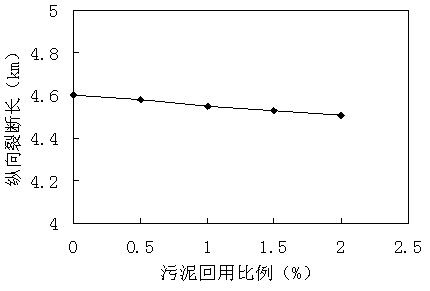

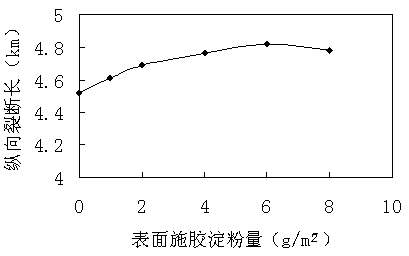

| Longitudinal fracture length | aaaaa | aaaaa |

| Longitudinal fracture length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com