Polyaniline-sulfonated graphene composite electrode material and preparation method thereof

A technology of sulfonated graphene and composite electrodes, which is applied to the manufacture of hybrid capacitor electrodes and hybrid/electric double-layer capacitors, can solve problems such as unfavorable clean production and unfavorable aniline monomers fully doping, etc., to ensure charge delocalization. degree, low preparation cost, and the effect of increasing doping degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

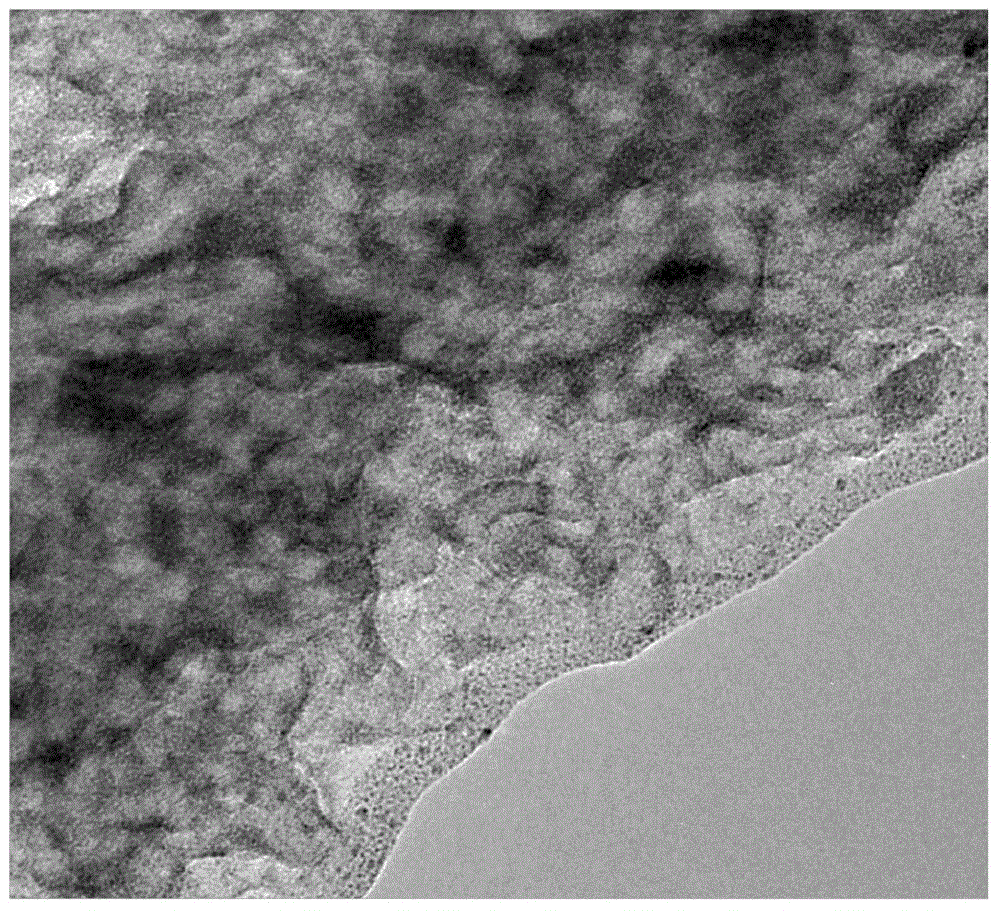

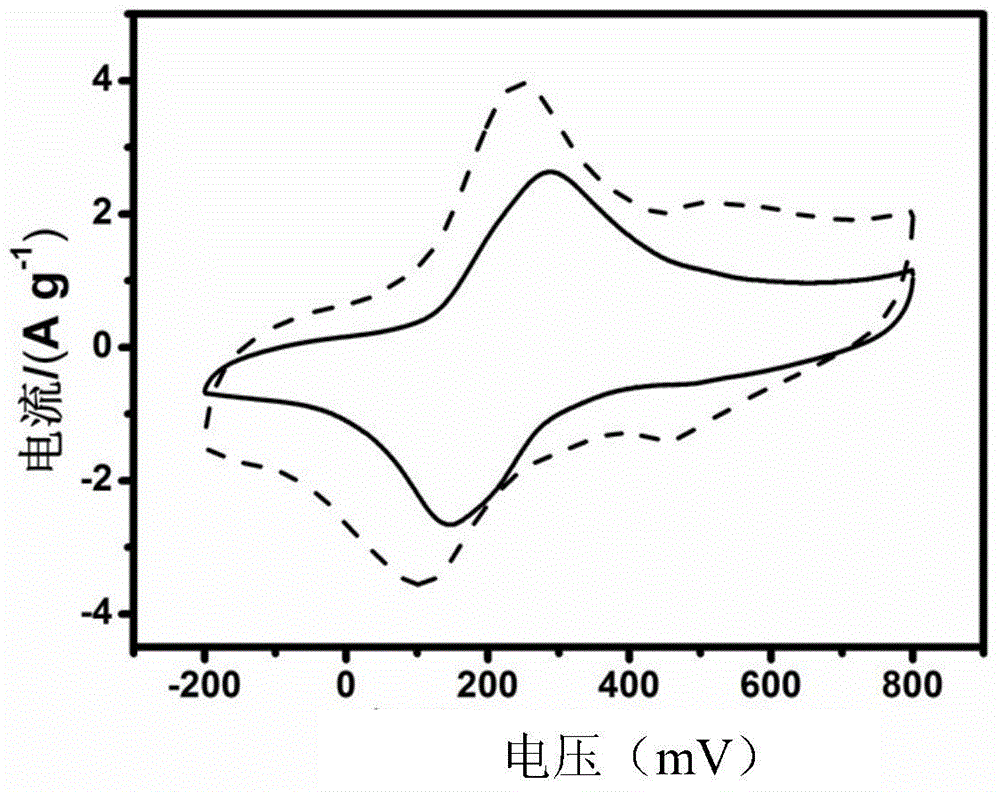

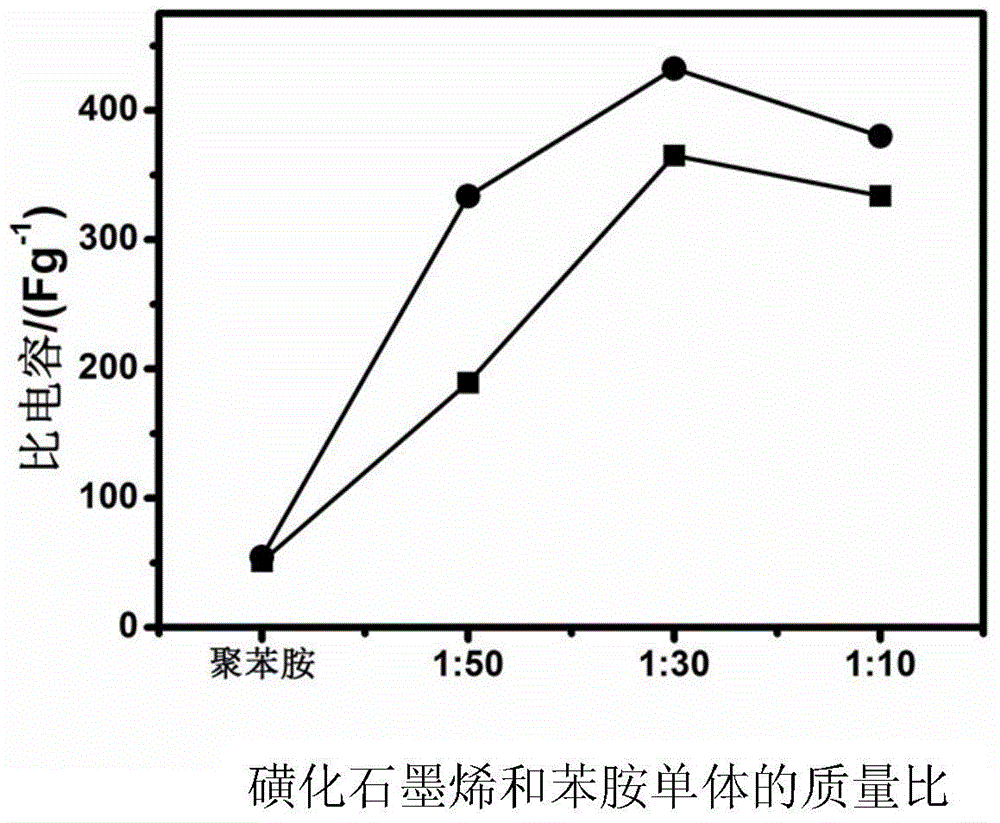

Embodiment 1

[0025] Dissolve 279mg of sulfonated graphene in 10mL of deionized water, use an ultrasonic cell pulverizer (200W) to ultrasonically disperse for 3 hours in an ice bath environment to make it uniformly dispersed; add 279mg of aniline monomer to the above solution, and then continue Sonicate for 1h, then stir at a constant speed for 12h in an ice bath. Aqueous ammonium persulfate solution was added dropwise, and the addition was completed within 0.5h, and then the reaction was continued for 4h. After the polymerization, the product was repeatedly washed with deionized water and ethanol until the color of the filtrate was colorless to remove residual monomers and initiators. Finally, the obtained product was vacuum-dried at 60° C. for 24 h to obtain a precursor. Then the precursor was dispersed in 1mol L -1 The sulfuric acid solution was stirred and soaked for 12 hours to fully dope the precursor with sulfuric acid, and then filtered to obtain the polyaniline / sulfonated graphen...

Embodiment 2

[0028] The sulfonated graphene of 5.58mg is dissolved in the deionized water of 10mL, uses the supersonic cell pulverizer (200W) to disperse ultrasonically in ice bath environment 3h to make it disperse evenly; Add the aniline monomer of 279mg in the above-mentioned solution, after that Continue to sonicate for 1h, and then stir at a constant speed for 12h in an ice bath. Aqueous ammonium persulfate solution was added dropwise, and the addition was completed within 0.5h, and then the reaction was continued for 4h. After the polymerization, the product was repeatedly washed with deionized water and ethanol until the color of the filtrate was colorless to remove residual monomers and initiators. Finally, the obtained product was vacuum-dried at 60° C. for 24 h to obtain a precursor. Then the precursor was dispersed in 1mol L -1 The sulfuric acid solution was stirred and soaked for 12 hours to fully dope the precursor with sulfuric acid, and then filtered to obtain the polyanil...

Embodiment 3

[0034] 27.9 mg of sulfonated graphene was dissolved in 10 mL of deionized water, and ultrasonically dispersed for 3 h in an ice-bath environment using an ultrasonic cell pulverizer (200 W) to make it uniformly dispersed; 279 mg of aniline monomer was added to the above solution, and then Continue to sonicate for 1h, and then stir at a constant speed for 12h in an ice bath. Aqueous ammonium persulfate solution was added dropwise, and the addition was completed within 0.5h, and then the reaction was continued for 4h. After the polymerization, the product was repeatedly washed with deionized water and ethanol until the color of the filtrate was colorless to remove residual monomers and initiators. Finally, the obtained product was vacuum-dried at 60° C. for 24 h to obtain a precursor. Then the precursor was dispersed in 1mol L -1 The sulfuric acid solution was stirred and soaked for 24 hours to fully dope the precursor with sulfuric acid, and then filtered to obtain the polyani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com