Catalyst system for synthesizing acetic acid through methanol carbonylation and application of catalyst system

A catalyst and chemical synthesis technology, applied in the direction of physical/chemical process catalyst, organic compound/hydride/coordination complex catalyst, carbon monoxide reaction to prepare carboxylic acid, etc. High cost and other problems, to achieve the effect of high product yield, simple process, and accelerated response speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

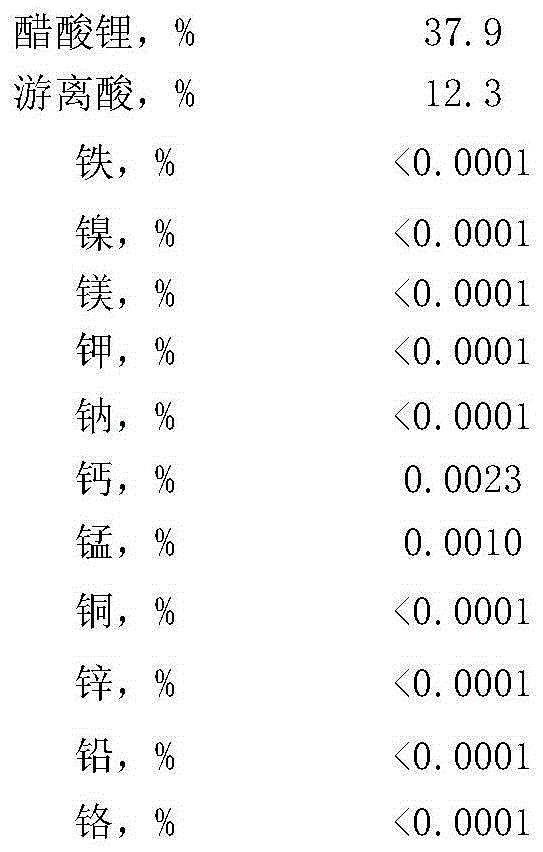

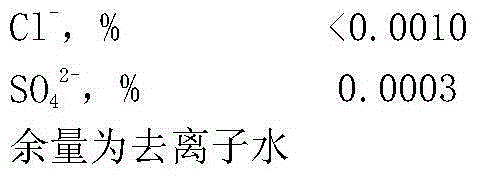

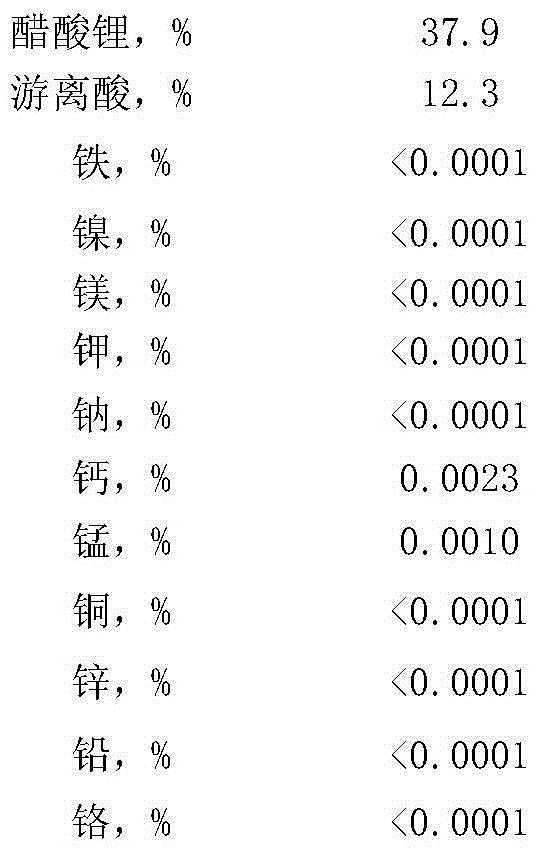

[0036] 1-1 Preparation of Lithium Acetate Aqua

[0037] (1) Add 99.9% lithium carbonate to the reaction kettle, add deionized water and stir until viscous, and prepare a lithium carbonate slurry with a mass fraction of 30-35%;

[0038] (2) After the sampling analysis is qualified, open the steam valve, and use the kettle jacket to heat the material in the kettle to 70°C;

[0039] (3) Turn on the fan of the negative pressure system to keep the reactor at a slight negative pressure of 3-5cmH2O;

[0040] (4) Open the acetic acid head tank valve, drip 99.8% acetic acid to react with it, and the rate of addition is the speed that makes the reaction liquid in the still not escape;

[0041] (5) Keep the temperature of steps (3) and (4) at 60°C until the gas no longer escapes, which is the end of the reaction. After the end of the reaction, the material is filtered to remove insoluble impurities to obtain the lithium acetate aqua product.

[0042] 1-2 Synthesis of acetic acid

[00...

Embodiment 2

[0048] 1-1 Preparation of Lithium Acetate Aqua

[0049] (1) Add 99.9% lithium carbonate to the reaction kettle, add deionized water and stir until viscous, and prepare a lithium carbonate slurry with a mass fraction of 30-35%;

[0050] (2) After the sampling analysis is qualified, open the steam valve, and use the kettle jacket to heat the material in the kettle to 70°C;

[0051] (3) Turn on the fan of the negative pressure system to keep the reactor at a slight negative pressure of 3-5cmH2O;

[0052] (4) Open the acetic acid head tank valve, drip 99.8% acetic acid to react with it, and the rate of addition is the speed that makes the reaction liquid in the still not escape;

[0053] (5) Keep the temperature of steps (3) and (4) at 70°C until the gas no longer escapes, which is the end of the reaction. After the end of the reaction, the material is filtered to remove insoluble impurities to obtain the lithium acetate aqua product.

[0054] 1-2 Synthesis of acetic acid

[00...

Embodiment 3

[0059] 1-1 Preparation of Lithium Acetate Aqua

[0060] (1) Add 99.9% lithium carbonate to the reaction kettle, add deionized water and stir until viscous, and prepare a lithium carbonate slurry with a mass fraction of 30-35%;

[0061] (2) After the sampling analysis is qualified, open the steam valve, and use the kettle jacket to heat the material in the kettle to 70°C;

[0062] (3) Turn on the fan of the negative pressure system to keep the reactor at a slight negative pressure of 3-5cmH2O;

[0063] (4) Open the acetic acid head tank valve, drip 99.8% acetic acid to react with it, and the rate of addition is the speed that makes the reaction liquid in the still not escape;

[0064] (5) keep step (3) and (4) temperature at 80 DEG C, until gas no longer escapes and is the end of the reaction, after the end of the reaction, the material is filtered to remove insoluble impurities to obtain the lithium acetate aqua product.

[0065] 1-2 Synthesis of acetic acid

[0066] (1) [R...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com