Silicon dioxide composite microspheres of metal or metal oxide nanoparticles and preparation method thereof

A technology of metal nanoparticles and silicon dioxide, applied in the direction of silicon dioxide, silicon oxide, etc., can solve the problems of destroying the properties of bulk materials and uneven properties of bulk materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

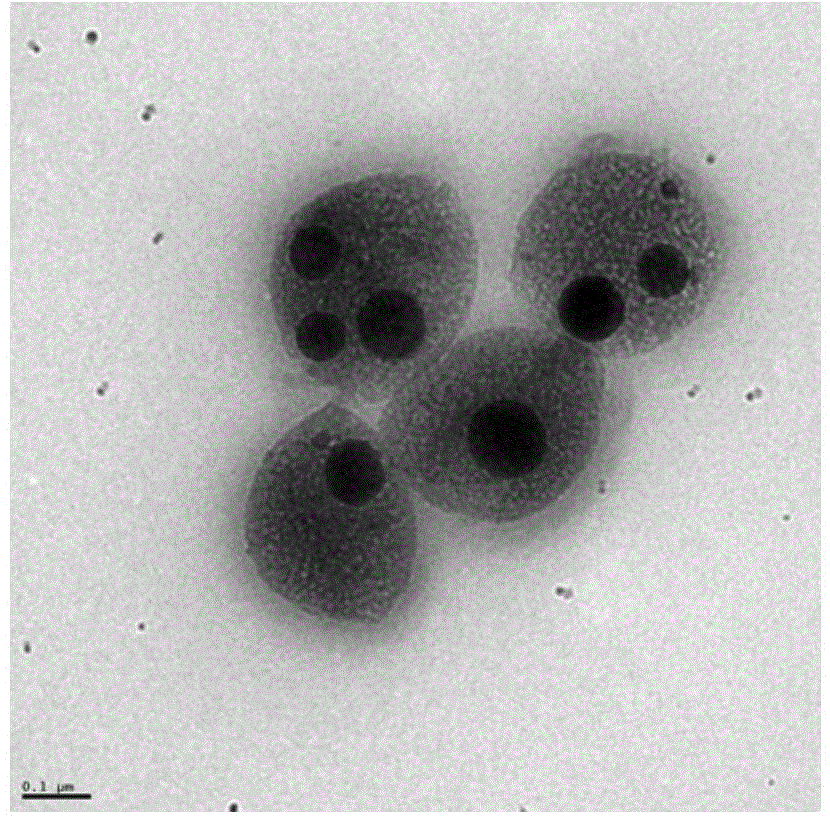

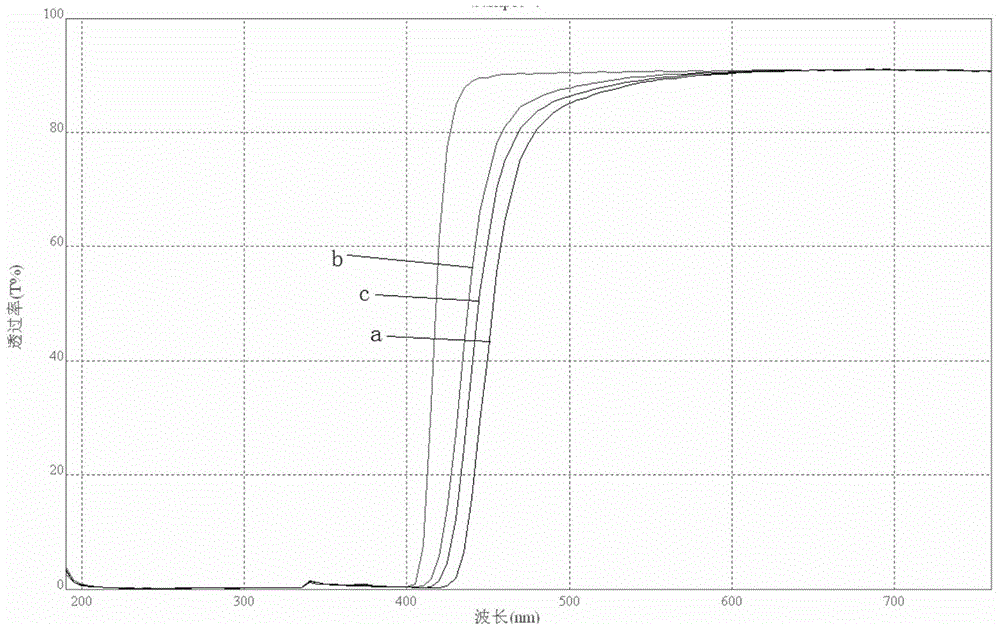

[0044] Embodiment 1: the silicon dioxide composite microsphere of metallic silver nanoparticle

[0045] 1) silver nitrate is dissolved in the aqueous solution of ethanol, and the mass concentration of ethanol is 50%, and the mass concentration of silver nitrate is 10%, obtains silver nitrate solution.

[0046] 2) The three-dimensional macroporous carbon template is immersed in the silver nitrate solution obtained in step 1), and dried to obtain a template deposited with silver nitrate. The mass ratio of silver nitrate deposited in the template was adjusted to 10% by repeatedly repeating this step. Then the template is isolated from air and heated to 450°C, the silver nitrate is decomposed into metallic silver and nitrogen dioxide, and the metallic silver is deposited in the template.

[0047] 3) Tetraethyl orthosilicate is dissolved in the mixed solution of ethanol, water, acid, the mass concentration of tetraethyl orthosilicate is 40%, the mass concentration of ethanol is 58...

Embodiment 2

[0053] Example 2: Silica Composite Microspheres of Iron Oxide Nanoparticles

[0054] 1) Ferric nitrate is dissolved in the aqueous solution of ethanol, and the mass concentration of ethanol is 50%, and the mass concentration of ferric nitrate is 10%, obtains ferric nitrate solution.

[0055] 2) Dip the three-dimensional macroporous carbon template into the ferric nitrate solution obtained in step 1), and dry to obtain a template deposited with ferric nitrate. By repeatedly repeating this step, the mass ratio of ferric nitrate deposited in the template was adjusted to 10%. Then the template is isolated from the air and heated to 450°C, the iron nitrate is decomposed into iron oxide and nitrogen dioxide, and the iron oxide is deposited in the template.

[0056] 3) Tetraethyl orthosilicate is dissolved in the mixed solution of ethanol, water, acid, the mass concentration of tetraethyl orthosilicate is 40%, the mass concentration of ethanol is 58%, the mass concentration of water...

Embodiment 3

[0061] Example 3: Silica Composite Microspheres of Metallic Copper Nanoparticles

[0062] 1) Copper nitrate is dissolved in the aqueous solution of ethanol, and the mass concentration of ethanol is 50%, and the mass concentration of copper nitrate is 10%, obtains copper nitrate solution.

[0063] 2) The three-dimensional macroporous carbon template is immersed in the copper nitrate solution obtained in step 1), and dried to obtain a template deposited with copper nitrate. By repeatedly repeating this step, the mass ratio of copper nitrate deposited in the template was adjusted to 10%. Then the template is isolated from air and heated to 450°C, the copper nitrate is decomposed into copper oxide and nitrogen dioxide, and the copper oxide is deposited in the template.

[0064] 3) Tetraethyl orthosilicate is dissolved in the mixed solution of ethanol, water, acid, the mass concentration of tetraethyl orthosilicate is 40%, the mass concentration of ethanol is 58%, the mass concent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com