A kind of evaporation crystallization method to ammonium chloride when producing potassium nitrate

A technology of evaporative crystallization and ammonium chloride, which is applied in the direction of ammonium halide, etc., can solve the problems of increased investment and operating costs, poor heat transfer effect of heat exchange surfaces, high investment and operating costs, etc., to eliminate the loss of effective heat transfer temperature difference, Effect of reduced collisions, low investment and operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

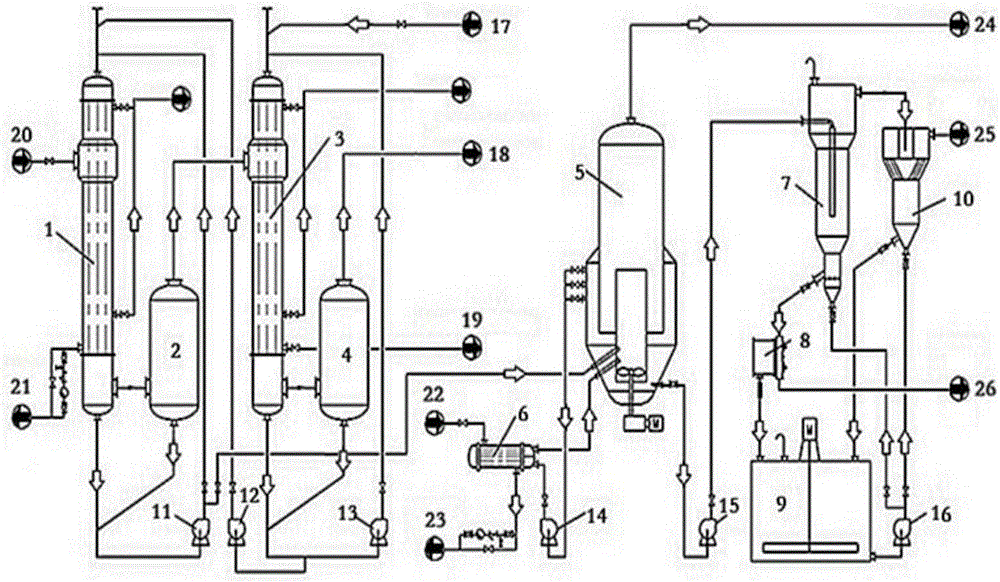

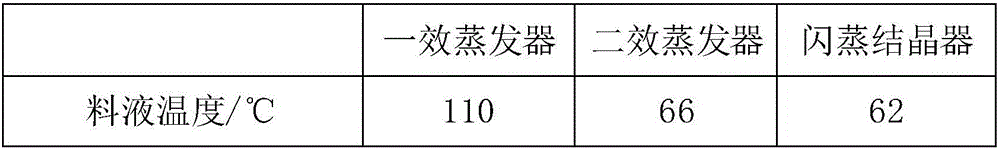

[0037] The temperature of the liquid to be crystallized is 40°C, the concentration of ammonium chloride in the liquid to be crystallized is 16.7%, and the feed rate of 57390kg / h enters the evaporation part, and the evaporation device is a double-effect evaporation evaporator. The state of materials in the evaporator and crystallizer is shown in Table 1 below:

[0038] Table 1 Feed liquid temperature and ammonium chloride concentration in evaporator and crystallizer

[0039]

[0040]

[0041] The average particle size of the ammonium chloride solution after the evaporative crystallization process is 0.15 mm. The average crystal particle size after the original forced circulation evaporative crystallization process is 0.10 mm. The new evaporative crystallization method is nearly larger than the old evaporative crystallization method. 0.5 times.

[0042] The unit energy consumption of the device of the continuous evaporation and crystallization process is 0.58kg steam / kg w...

Embodiment 2

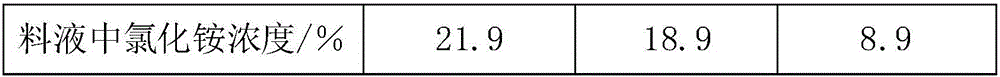

[0045] The temperature of the liquid to be crystallized is 30°C, the concentration of ammonium chloride in the liquid to be crystallized is 16.6%, and the feed rate of 172170kg / h enters the evaporation part. The evaporation device is a three-effect evaporation evaporator, and the ammonium chloride mother liquor is fed The three-effect evaporator is preheated by the preheater. The state of materials in the evaporator and crystallizer is shown in Table 2 below:

[0046] Table 2 Feed liquid temperature and ammonium chloride concentration in evaporator and crystallizer

[0047]

[0048] The unit energy consumption of the device of the continuous evaporation and crystallization process is 0.42kg steam / kg water, which is 27.6% lower than that of Example 1.

[0049] The equipment capacity of this continuous evaporation and crystallization process is: 3 people / shift for crystallization operation, covering an area of 35m in length and 18m in width.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com