Composite flocculant for paper sludge dewatering

A technology of compound flocculant and papermaking sludge, applied in water/sludge/sewage treatment, sludge treatment, biological sludge treatment, etc., can solve the problem of not being able to give instructions or guidance for flocculant matching or coordination, synergistic effect Or the mechanism of synergistic effect is not clear, and it does not have the ability to remove all kinds of water in an all-round way, so as to improve the surface charge and interface activity, increase the radius, and reduce the compressibility.

Active Publication Date: 2016-06-01

HANGZHOU EXCE FILTER PRESS

View PDF4 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] In the prior art, papermaking sludge usually needs to be chemically conditioned by adding chemical reagents to achieve high dehydration efficiency. Commonly used chemical reagents include organic polymer flocculants and inorganic flocculants. Commonly used organic polymer flocculants include polyacrylamide , inorganic flocculants include aluminum chloride, ferric chloride, polyaluminum chloride, polyaluminum silicate, polyaluminum ferric chloride, etc.; however, studies have shown that adding conditioners can only increase the dehydration speed, and have no effect on the amount of sludge dewatering Too much increase; a single flocculant can only act on one or two types of water in paper sludge, and the actual effect on dehydration is limited; there are also techniques for using inorganic and organic flocculants in combination in the prior art, but the current retrieval None of the technical solutions obtained has the ability to comprehensively remove all kinds of water, and there is no significant increase in the amount of water removed; therefore, it is urgent to find new conditioning agents to change the degree of dehydration of paper sludge

[0005] In addition, there are many types of flocculants in the prior art, and the types of various inorganic or organic flocculants and flocculants with various functional groups may reach tens of thousands. However, when these flocculants are combined and matched, due to The mechanism of the synergy or synergistic effect between the flocculants is not clear, and the prior art cannot give instructions or guidance for the collocation or coordination between the flocculants, and only rely on repeated combinations and attempts to obtain better flocculation effects The flocculant has a certain degree of contingency and unpredictability, and the probability of failure is high; the existing commercial flocculant in the prior art still has the problem of high price, which leads to the high operating cost of sludge treatment;

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

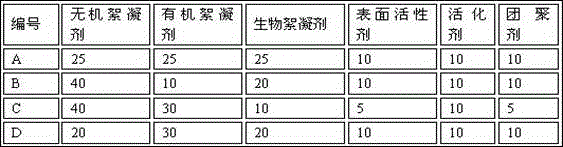

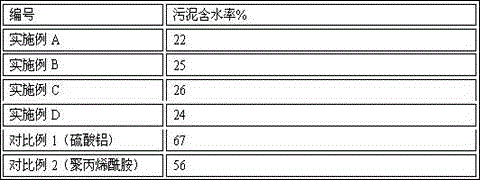

[0026] Papermaking sludge with a moisture content of 90% was selected as the test object, and the flocculant with the following weight composition was configured (see Table 1):

[0027] Table 1

[0028]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to a flocculant, in particular to a paper sludge dewatering composite flocculant. The flocculant provided by the invention consists of an inorganic flocculant, an organic flocculant, a biological flocculant, a surfactant, an activating agent and an agglomeration solution. According to the paper sludge dewatering composite flocculant provided by the invention, the dehydration property of the paper sludge can be improved, the activity of the paper sludge can be improved, the agglomerate property of the paper sludge can be improved, and the cost can be reduced.

Description

technical field [0001] The invention relates to the technical field of sludge treatment, in particular to a composite flocculant for papermaking sludge treatment. Background technique [0002] The amount of sludge treated by papermaking wastewater is large, generally 5 to 10 times that of municipal sewage treatment plants of the same scale. According to the survey, the amount of sludge produced by my country's pulp and paper enterprises is more than 5 million tons every year. The sludge in the papermaking wastewater treatment system can be divided into four types: primary sludge, secondary sludge, tertiary sludge and mixed sludge. The primary sludge is composed of sieve residue and a large amount of inorganic fillers, which can form a relatively hard mud cake, which is easy to dehydrate and has a high dryness after dehydration; the secondary sludge is often called activated sludge, which is generally removed by biochemical methods. Organic pollutants in colloidal state and...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C02F11/14C02F11/02

CPCC02F11/02C02F11/14C02F2303/06Y02W10/20

Inventor 凌伟明丁海明丁茂潮金鹤生金连平

Owner HANGZHOU EXCE FILTER PRESS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com