Biodegradable non-woven fabric and preparation method thereof

A biodegradable, non-woven technology, used in non-woven fabrics, textiles and papermaking, etc., can solve the problem of not many reports, and achieve the effects of good flexibility, low energy consumption, and excellent filtration efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

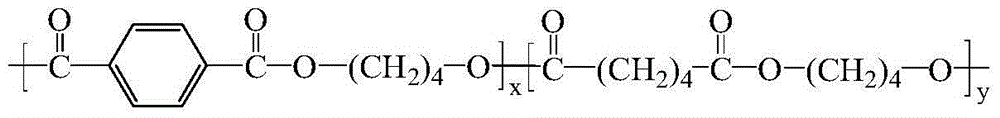

[0028] Dry poly(butylene adipate / terephthalate) (PBAT) particles with a number average molecular weight of 30,000 in vacuum at 60°C for 48 hours so that the moisture content is <100ppm;

[0029] Then the dried PBAT particles are heated by a screw extruder, the melting temperature is 200°C, and extruded into a melt. sec, the temperature is 190 ° C high-pressure hot air injection, the PBAT polyester melt is stretched into ultra-fine fibers, condensed on the drum receiver with a distance of 5 cm from the nozzle, and the drum speed of the receiver is 20r / min, automatically Bonded into a non-woven fabric, after cooling, the non-woven fabric was removed from the drum with a blade and placed in a drying oven to dry and shape. The setting temperature was 80°C, and the setting time was 20 hours. The biodegradable non-woven fabric was obtained.

Embodiment 2

[0031] Dry poly(butylene adipate / terephthalate) (PBAT) particles with a number average molecular weight of 50,000 in vacuum at 70°C for 40 hours, so that the moisture content is <100ppm;

[0032] Then the dried PBAT particles are heated by a screw extruder with a melting temperature of 220°C and extruded into a melt. sec, the temperature is 250 ° C high-pressure hot air injection, the PBAT polyester melt is stretched into ultra-fine fibers, condensed on the drum receiver 10cm away from the nozzle, the drum speed of the receiver is 25r / min, automatic Bonded into a non-woven fabric, after cooling, the non-woven fabric was removed from the drum with a blade and placed in a drying oven for drying and setting. The setting temperature was 85°C and the setting time was 15 hours. The obtained biodegradable non-woven fabric was obtained.

Embodiment 3

[0034] Dry poly(butylene adipate / terephthalate) (PBAT) particles with a number average molecular weight of 55,000 in vacuum at 80°C for 36 hours so that the moisture content is <100ppm;

[0035] Then the dried PBAT particles are heated by a screw extruder, the melting temperature is 240°C, and extruded into a melt. sec, the temperature is 270 ° C high-pressure hot air injection, the PBAT polyester melt is stretched into ultra-fine fibers, condensed on the drum receiver 20cm away from the nozzle, the drum speed of the receiver is 27r / min, automatic Bonded into a non-woven fabric, after cooling, remove the non-woven fabric from the drum with a blade and put it in a drying oven to dry and shape. The setting temperature is 90 ° C, and the setting time is 10 hours. The obtained biodegradable non-woven fabric.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com