Medical semi-degraded titanium-magnesium composite microsphere bone filling material

A technology of composite microspheres and composite materials, which is applied in the field of biomedical engineering, can solve the problems of low strength and stiffness, and achieve high strength, stability, and high elastic modulus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

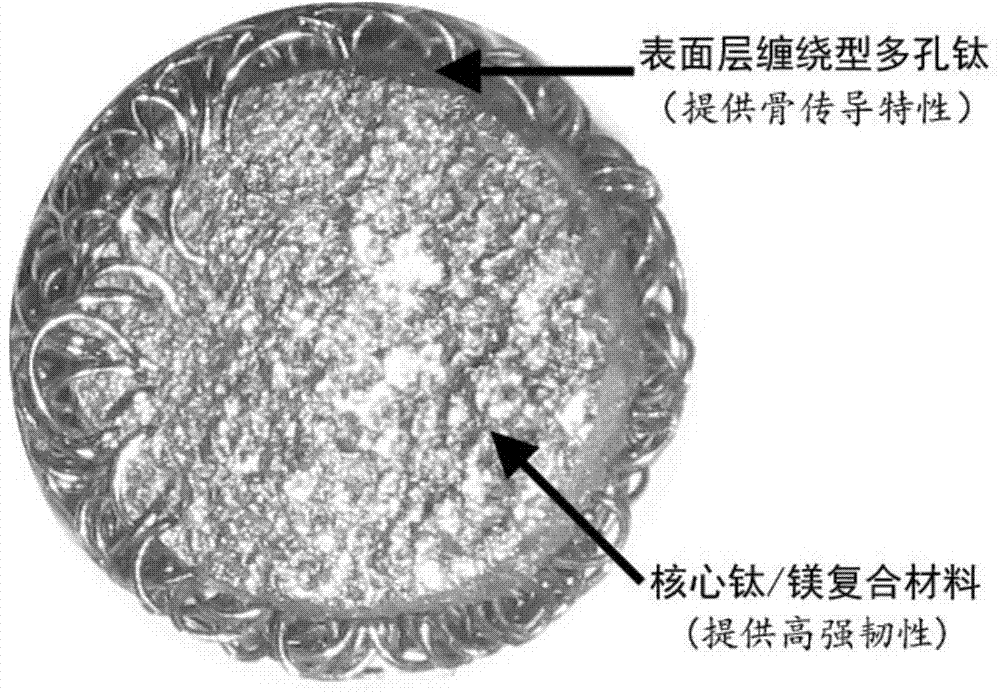

[0028] A 0.05mm titanium wire is wound into a porous titanium microsphere with a porosity of 10% and a diameter of 1mm, and then the magnesium alloy melt added with Zn and Ca elements is injected into the porous titanium microsphere to prepare a titanium-magnesium composite microsphere with a diameter of 1mm , wherein the volume ratio of the composite two phases at the center of the microsphere is: titanium / magnesium=0.9:0.1, the surface thickness of the microsphere is about 0.2mm, the porosity is 10%, and the inner space is coated with biological activity on the surface. The compressive strength of titanium-magnesium composite microspheres reaches 120MPa; the elastic modulus reaches 15GPa.

Embodiment 2

[0030] A 1mm titanium wire is used to wind a porous titanium microsphere with a porosity of 50% and a diameter of 10mm, and then the magnesium melt added with Zr and Ca elements is injected into the porous titanium microsphere to prepare a titanium-magnesium composite microsphere with a diameter of 10mm. , the volume ratio of the composite two phases at the center of the microsphere is: titanium / magnesium=0.5:0.5, the surface thickness of the microsphere is about 1.5mm, the porosity is 50%, and the inner space is loaded with osteoinductive factors and antibacterial silver ions. The compressive strength of titanium-magnesium composite microspheres reaches 116MPa; the elastic modulus reaches 13GPa.

Embodiment 3

[0032] A 0.1mm titanium alloy wire is used to wind a porous titanium microsphere with a porosity of 90% and a diameter of 3mm, and then the molten magnesium is injected into the porous titanium microsphere to prepare a titanium-magnesium composite microsphere with a diameter of 3mm. The volume ratio of the composite two phases is: titanium / magnesium = 0.1:0.9, the surface of the core of the microsphere is coated with a corrosion-resistant biological coating, the thickness of the surface of the microsphere is about 0.5mm, the porosity is 90%, and the internal space is loaded to promote growth strontium and anti-inflammatory drugs. The compressive strength of titanium-magnesium composite microspheres reaches 15MPa; the modulus of elasticity reaches 3GPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com