System and method for improving preparation speed and efficiency of solar thermo-chemical fuel

A chemical fuel, solar thermal technology, applied in solar heating systems, solar thermal energy, solar thermal power generation, etc., can solve the problems of immaturity, disadvantage, and difficulty in heat recovery and utilization of heat exchangers, so as to improve mechanical performance, avoid use, The effect of improving conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

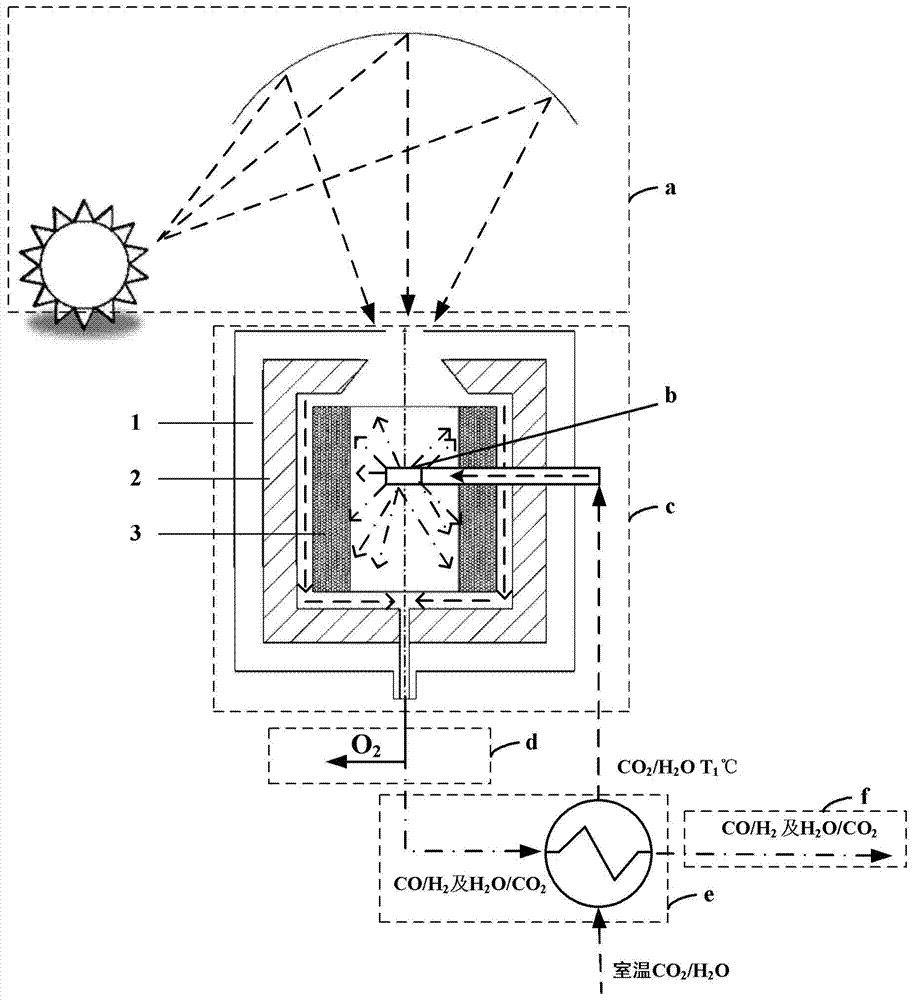

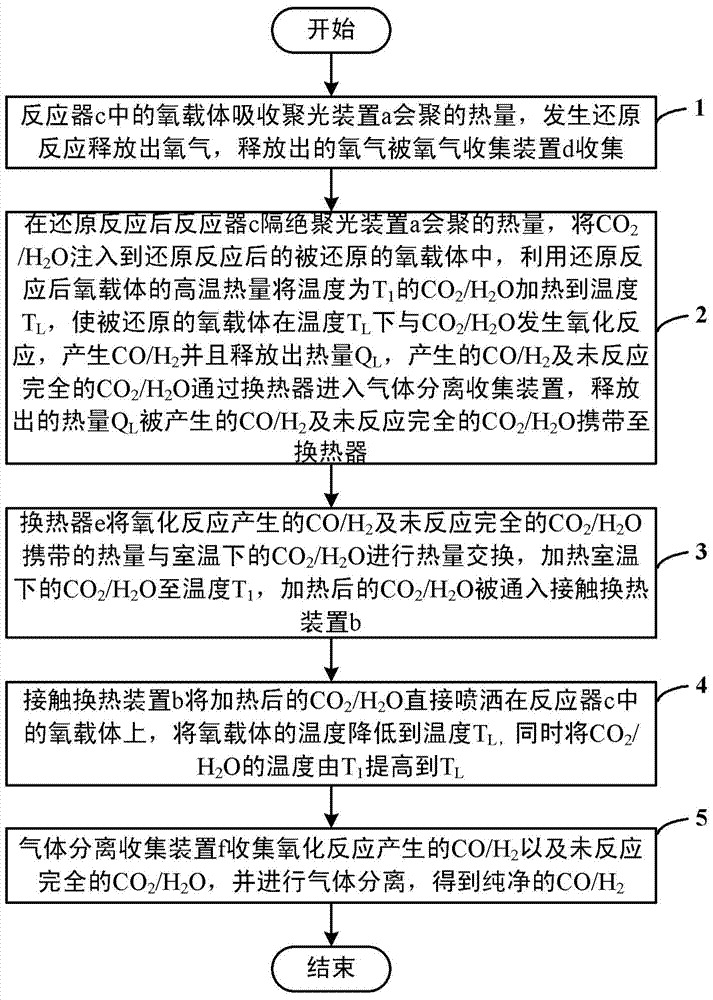

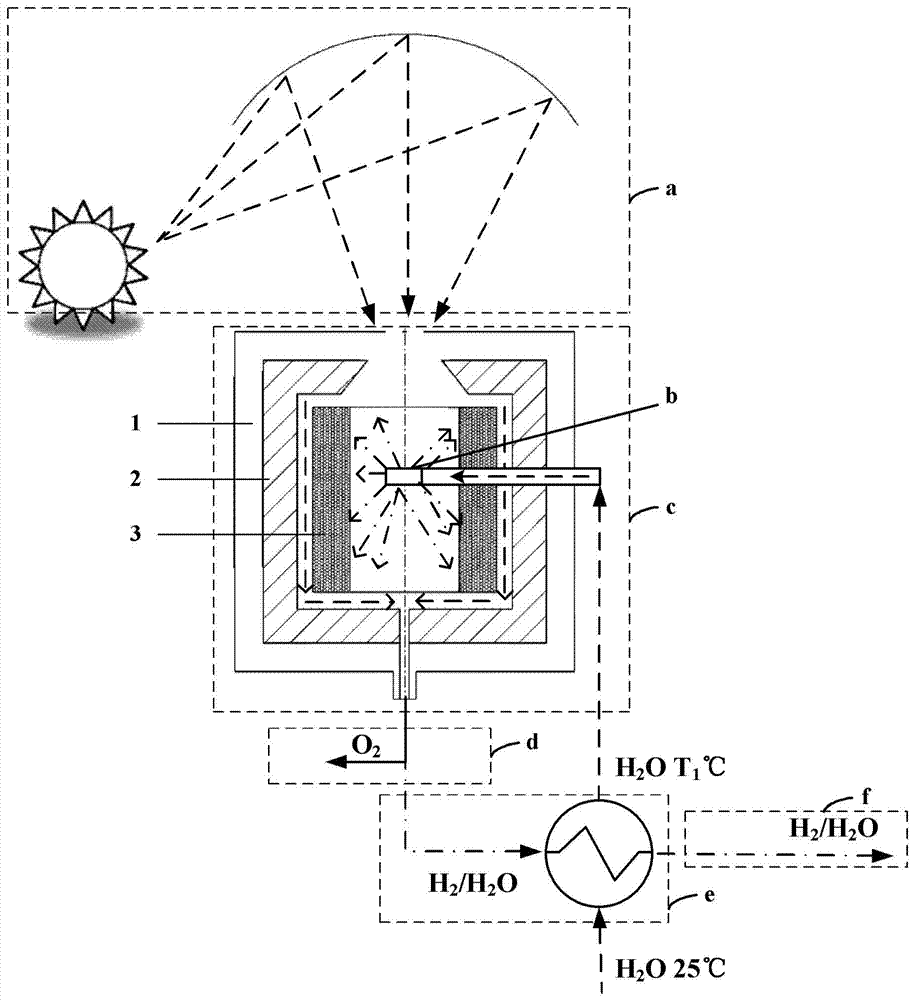

[0058] The invention provides a system and method for improving the speed and efficiency of solar thermochemical fuel production, using cerium oxide as a catalyst, the process of preparing CO and H 2 The principle is the same, including two main reaction processes: high temperature T H The lower oxygen carrier (such as cerium oxide) absorbs solar heat and undergoes a reduction reaction to release O 2 ; low temperature T L Next, CO is introduced into the reduced oxygen carrier 2 / H 2 O is oxidized to release CO / H 2 . There are two items in the energy input part: the cerium oxide from the low temperature T L Heated to high temperature T H The required heat Q 氧化铈,加热 and high temperature T H The heat Q absorbed by re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com