Zirconium oxide monodisperse active spinel powder and preparation method thereof

A technology for dispersing active, spinel powder, applied in the field of spinel refractory raw materials, can solve the problems of difficult uniform dispersion, cross-section accidents, etc., to achieve the effects of longevity, inhibition of excessive growth, and improvement of thermal shock resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

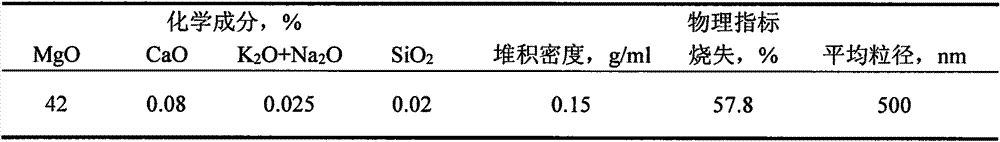

[0021] Activated alumina micropowder and nano light magnesium carbonate are used as raw materials. The physical and chemical indicators of nano light magnesium carbonate are shown in Table 1.

[0022] Step 1, putting 51.6wt% activated alumina micropowder and 48.4wt% nano light magnesium carbonate into a ball mill for co-grinding for 30 hours to obtain a uniform co-grinding material;

[0023] Step 2, put the co-grinding material into the mixer, add 3wt% pregelatinized starch of the co-grinding material, and 13 wt% alkaline zirconium sol of the co-grinding material in turn, mix for 20 minutes, and then seal and trap the material for 22 hours;

[0024] Step 3, put the trapped material into the mold, and press molding;

[0025] Step 4: Naturally dry the green body at room temperature for 20 hours, dry at 150°C for 24 hours, then put it into a high-temperature kiln and calcinate at 1300°C for 6 hours;

[0026] In step five, the calcined material is crushed, coarsely ground, and f...

Embodiment 2

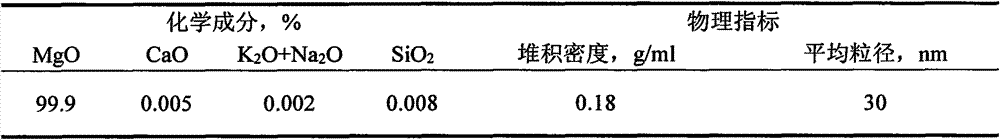

[0029] Activated alumina micropowder and nano light magnesium oxide are used as raw materials. The physical and chemical indicators of nano light magnesium oxide are shown in Table 2.

[0030] Step 1, putting 71.7wt% activated alumina micropowder and 28.3wt% nano light magnesium oxide into a ball mill for co-grinding for 40 hours to obtain a uniform co-grinding material;

[0031] Step 2, put the co-grinding material into the mixer, add 2 wt% acetate starch of the co-grinding material and 10 wt% alkaline zirconium sol of the co-grinding material in turn, mix for 18 minutes, and then seal and trap the material for 24 hours;

[0032] Step 3, put the trapped material into the mold, and press molding;

[0033] Step 4: Naturally dry the body at room temperature for 24 hours, and then dry it at 160°C for 24 hours; then place it in a high-temperature kiln and calcinate it at 1350°C for 8 hours;

[0034] In step five, the calcined material is crushed, coarsely ground, and finely grou...

Embodiment 3

[0037] Activated alumina micropowder, nano light magnesium carbonate and nano light magnesium oxide are used as raw materials.

[0038] Step 1, putting 64.2wt% activated alumina micropowder, 17.9wt% nanometer light magnesium carbonate and 17.9wt% nanometer light magnesium oxide into a ball mill for co-grinding for 40 hours to obtain a uniform co-grinding material;

[0039] Step 2, put the co-grind into the mixer, add the pregelatinized starch of co-grind 1wt%, the acetate starch of co-grind 1.5wt%, the basic zirconium sol of co-grind 12wt%, and mix for 22 minutes, then Airtight and trapped material for 24 hours;

[0040] Step 3, put the trapped material into the mold, and press molding;

[0041] Step 4: Naturally dry the green body at room temperature for 24 hours, then dry it at 150°C for 24 hours, then place it in a high-temperature kiln and calcinate it at 1320°C for 7 hours;

[0042] In step five, the calcined material is crushed, coarsely ground, and finely ground, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com