High-heat-resistance high-strength polylactic acid/inorganic fiber composite material or product and preparation method thereof

A technology of inorganic fibers and composite materials, which is applied in the field of polymer composite materials and its preparation, can solve the problems of petroleum resource consumption environment, inability to strengthen polylactic acid, and lack of mechanical strength, so as to broaden the application range and improve the interface stress transfer efficiency , Enhance the effect of interface interaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

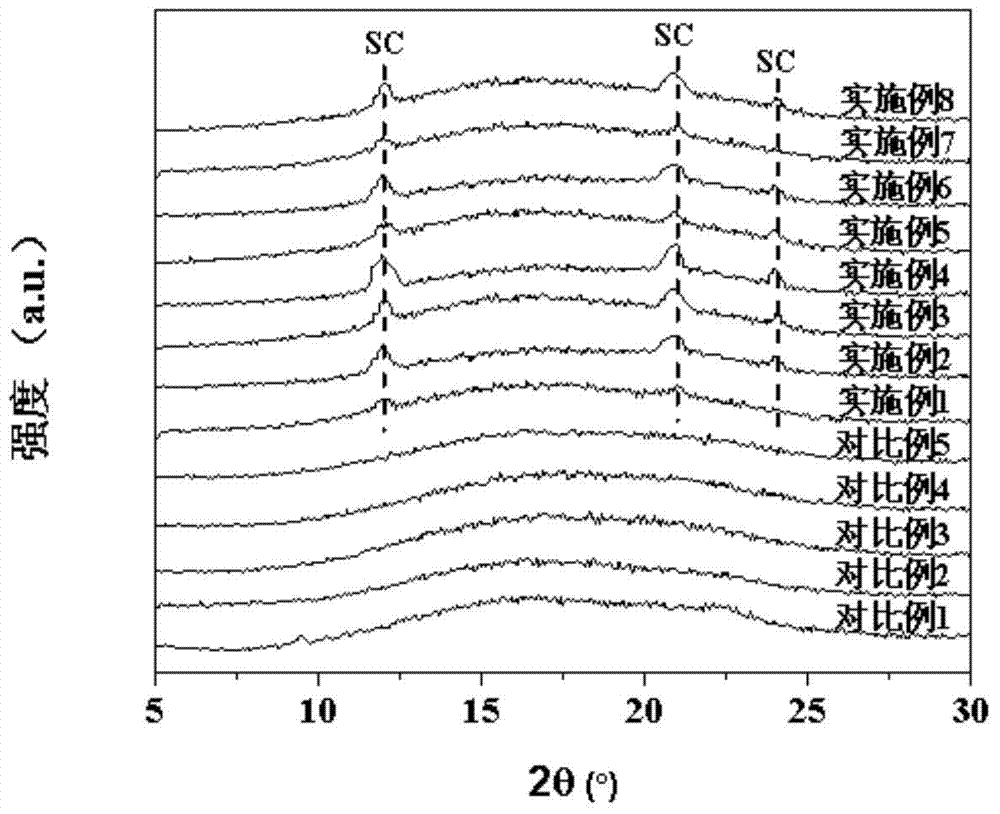

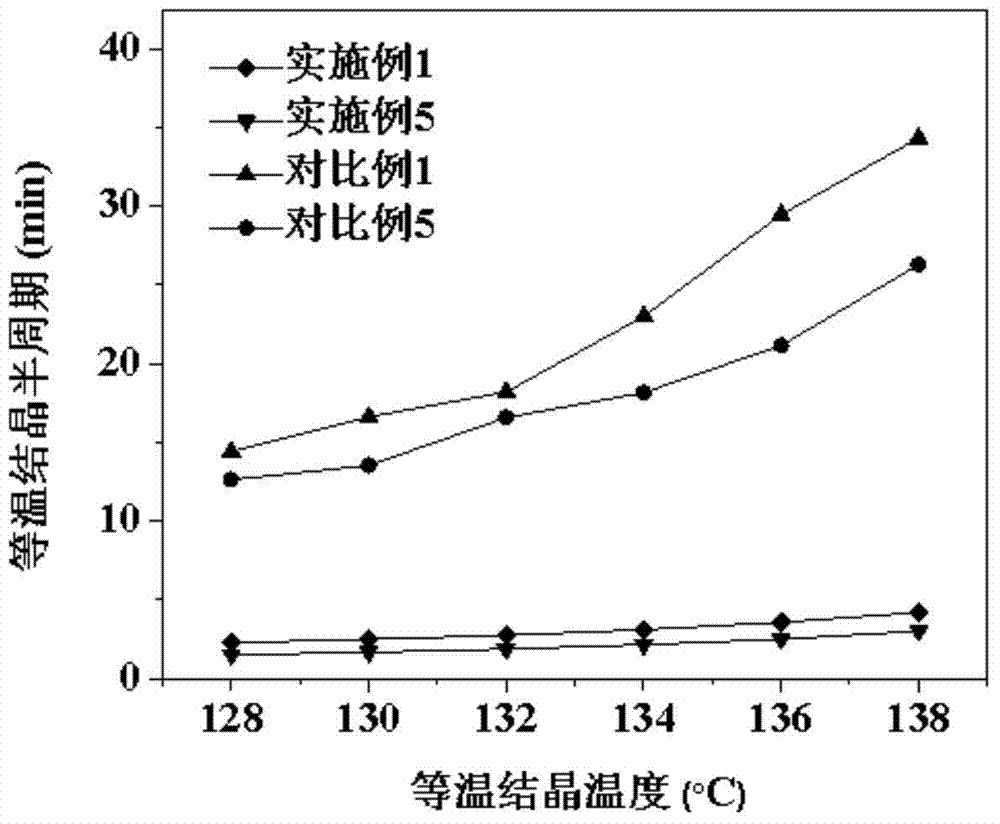

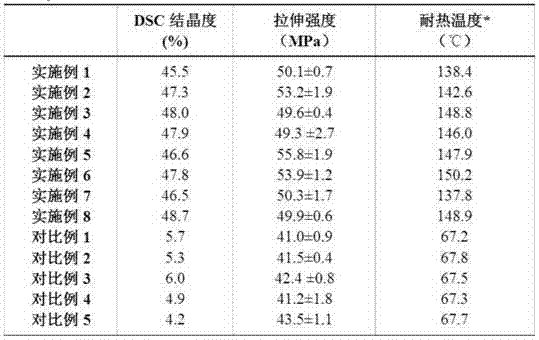

Examples

Embodiment 1

[0031] 1) Grafting PDLA by in-situ polymerization grafting method: 0.4 g of hydroxylated carbon nanotubes were first dispersed in 150 ml of anhydrous toluene, and then ultrasonically dispersed for 1 h, and then 16 g of D-lactide monomer with a purity of 99.5% and 0.13 ml of catalyst stannous octoate, and then reacted at 120°C for 10 hours under nitrogen atmosphere; the product was completely dissolved in chloroform and vacuum filtered to remove polylactic acid molecules that had not undergone grafting reaction; finally, the suction filtered product was dried to a moisture content of Below 200ppm, the weight average molecular weight is 5×10 3 g·mol, PDLA grafted carbon nanotubes with an optical purity of 99.5%;

[0032] 2) Inorganic fiber modified by PDLA grafting with a weight average molecular weight of 5×10 4 The PLLA matrix with g mol and optical purity of 98% is completely dissolved in chloroform. After stirring and mixing evenly, the masterbatch is prepared by co-precipi...

Embodiment 2

[0035] 1) In situ grafting on the surface of hydroxylated carbon nanotubes by in situ polymerization and grafting to obtain a weight average molecular weight of 9×10 3 g mol, optical purity is 99.5% PDLA, the grafting reaction time is 16h, all the other conditions are the same as embodiment 1;

[0036] 2) Inorganic fiber modified by grafting PDLA with a weight average molecular weight of 1.5×10 5 The PLLA matrix with g·mol and optical purity of 95% is completely dissolved in dichloromethane. After stirring and mixing evenly, the masterbatch is prepared by co-precipitation with absolute ethanol, and vacuum-dried at 60°C for 24 hours for later use. The content of inorganic fiber is 10.0wt%;

[0037] 3) Premix the obtained masterbatch and the vacuum-dried PLLA matrix according to the inorganic fiber content in the obtained composite material to be 3.0wt%, and then add it to a Haake micro extruder at 160°C for melt mixing and granulation. The polylactic acid / carbon nanotube comp...

Embodiment 3

[0039] 1) Grafting PDLA by chemical coupling and grafting method: first disperse 0.4g of aminated carbon nanotubes in 150ml of anhydrous chloroform, then ultrasonically disperse for 1 hour, and then add 15g of them with a weight average molecular weight of 5×10 3 g·mol, PDLA with an optical purity of 98%, and then reacted at 120°C for 24 hours under a nitrogen atmosphere; the product was completely dissolved in chloroform and vacuum filtered to remove PDLA molecules that had not undergone grafting reaction; The product is dried until the water content is lower than 200ppm to obtain a weight average molecular weight of 5×10 3 g·mol, PDLA grafted carbon nanotubes with an optical purity of 98%;

[0040] 2) Inorganic fiber modified by grafting PDLA with a weight average molecular weight of 1.1×10 5 The PLLA matrix with g mol and optical purity of 98.5% is completely dissolved in dichloromethane. After stirring and mixing evenly, the masterbatch is prepared by co-precipitation wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Moisture content | aaaaa | aaaaa |

| Weight average molecular weight | aaaaa | aaaaa |

| Weight average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com