Novel nitride quantum well infrared detector and manufacturing method thereof

An infrared detector and quantum well technology, applied in the field of infrared detectors, can solve the problems of poor crystal quality of nitride materials, reduced signal-to-noise ratio, unfavorable for photocurrent signal extraction, etc., and achieves the effect of reducing adverse effects and efficiently extracting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described through the embodiments below in conjunction with the accompanying drawings.

[0035] In this example, prepare 10 cycles of Al 0.3 Ga 0.7 N / GaN quantum well infrared detector.

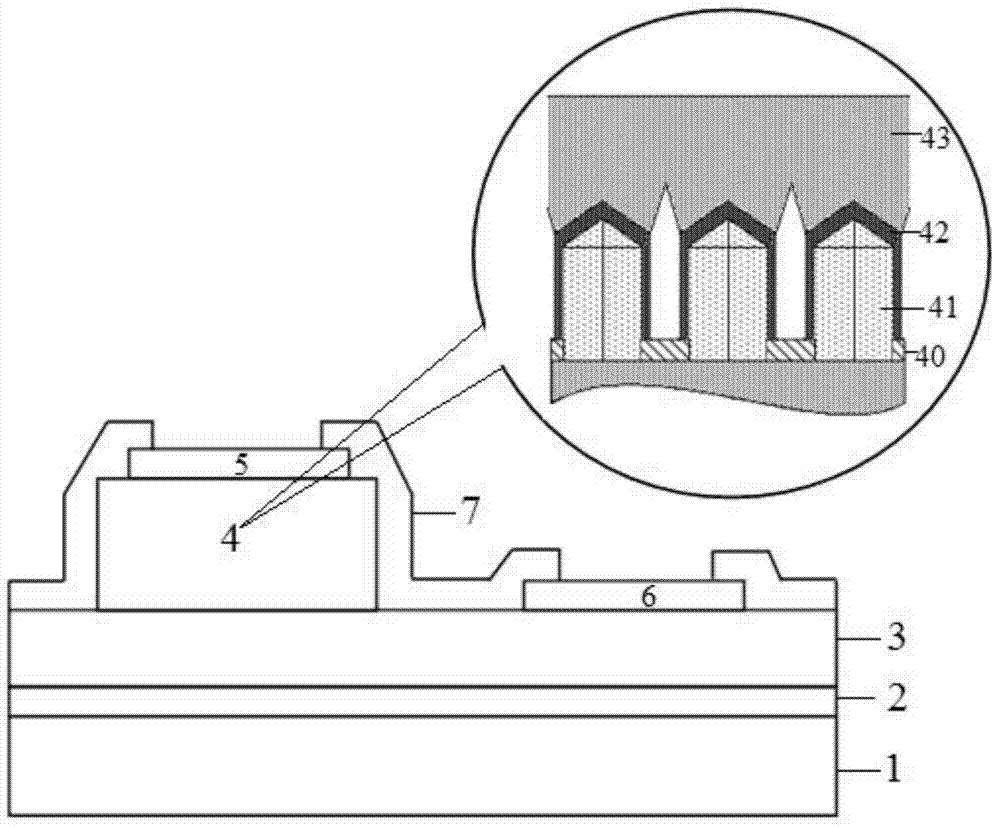

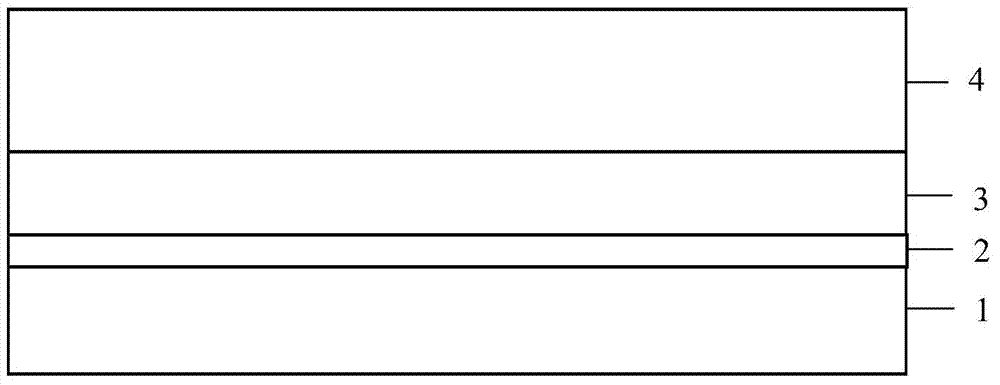

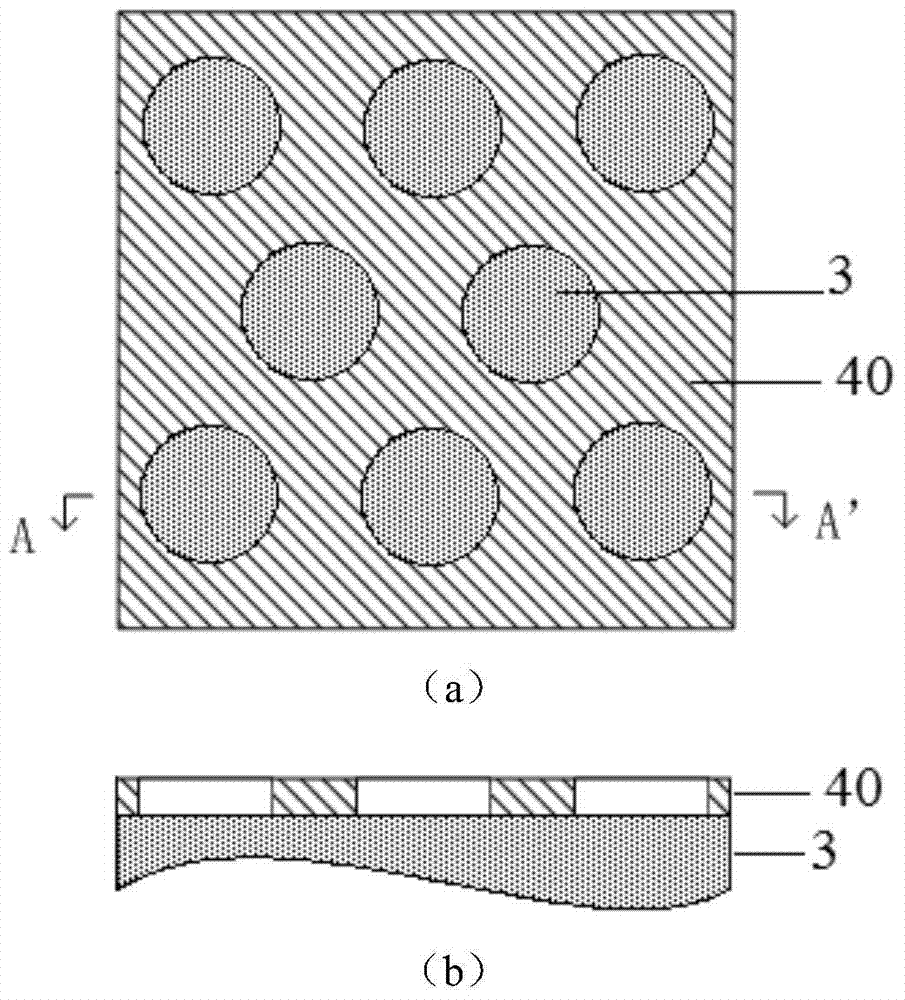

[0036] like figure 1 As shown, the quantum well infrared detector of the present embodiment comprises: substrate 1, buffer layer 2, bottom electrode contact layer 3, compound layer 4, top electrode 5, bottom electrode 6 and passivation layer 7; On substrate 1 Growing a buffer layer 2; growing a bottom electrode contact layer 3 on the buffer layer 2; a composite layer 4 and a top electrode 5 on a part of the bottom electrode contact layer 3; a bottom electrode 6 on a part of the bottom electrode contact layer 3; The sides of the top electrode 5 and the bottom electrode 6 are covered with a passivation layer 7 ; wherein, the composite layer 4 includes: a mask layer 40 , a nanopillar array 41 , multiple quantum wells 42 and a top electrode contact ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com