Precise digitized seedling system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

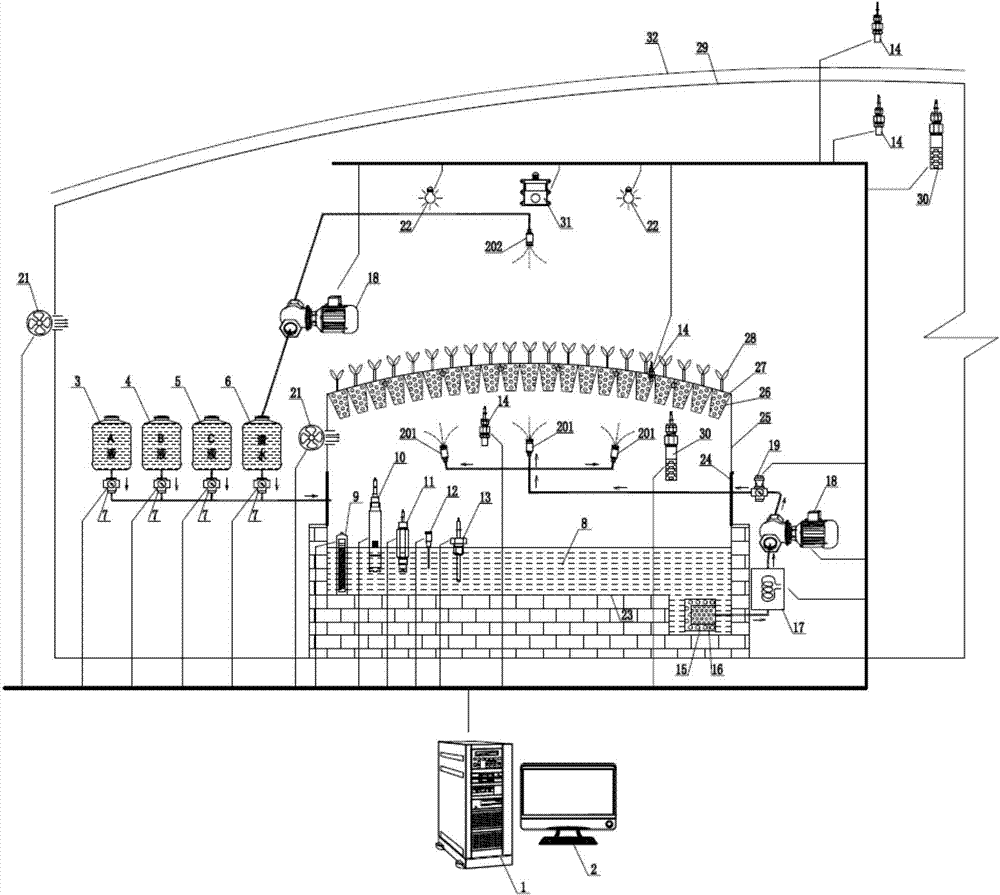

[0030] like figure 1 As shown, the digital precision seedling raising system in the present invention involves the following structures:

[0031] 1. Greenhouse: To build or use existing plastic greenhouses or greenhouses, the greenhouses or greenhouses are required to be transparent, airtight, have vents that can be opened and closed, and install insect-proof nets and sunshade nets. The specifications of the greenhouse or greenhouse can be built according to existing conditions or needs. The greenhouse or greenhouse mainly provides a relatively closed space environment for lighting, heat preservation, and insect prevention, and the digital precision aerosol seedling raising system can be appropriately matched according to the actual space of the greenhouse.

[0032] 2. Cultivation institutions: Cultivation institutions include cultivation brackets, liquid reservoirs, aerosol chambers, and seedling trays. The reservoir is 30cm deep, 110cm wide, and the bottom surface has a sl...

Embodiment 2

[0071] The using method of the digital precision seedling raising system provided by the present invention is as follows:

[0072] Build, install, and debug various mechanisms and devices.

[0073] Prepare substrate and seeds; prepare nutrient solution, acid solution and lye solution according to the recipe. Substrates, seeds, and nutrient solutions are determined according to the seeds and cultivation goals.

[0074] Prepare a seedling tray, and select a nursery tray of corresponding specifications according to the variety and cultivation goals of the seedlings.

[0075] The nutrient pool is filled with nutrient solution, each storage tank is filled with nutrient solution mother solution, and the acid solution and the lye solution are respectively filled into the acid solution bucket and the lye solution bucket.

[0076] Substrate disinfection, disinfection and cleaning of seedling trays, disinfection and cleaning of cultivation racks.

[0077] Load the substrate into seed...

Embodiment 3

[0085] The effect of the digital precision seedling breeding system:

[0086] The digital precision seedling raising system provided by the present invention is compared with the conventional seedling raising method (hydroponics) seedling raising. The two adopt tobacco seeds from the same tobacco leaf production area, and they are sown and run on the same day. Table 2 shows the comparison of seedling raising between the two, and Table 3 shows the comparison of seedling quality between the two.

[0087] Table 2

[0088]

[0089] table 3

[0090]

Plant height cm

Root weight (g / plant)

root length cm

Stem diameter mm

this invention

6

0.875

75

6

conventional nursery

4.8

0.65

35

4.5

[0091] 1. Adopting the tobacco seedlings cultivated by the technology of the present invention, the field planting shows as significantly improving the yield per unit area, hierarchical structure, and output value per...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com