Lithium ion battery composite anode material and preparation method thereof

A composite cathode material, lithium-ion battery technology, applied in battery electrodes, batteries, positive electrodes, etc., can solve the problems of low coating amount, easy to fall off, limited interaction effect, etc., and achieve good rate performance, stable structure, and cycle. stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

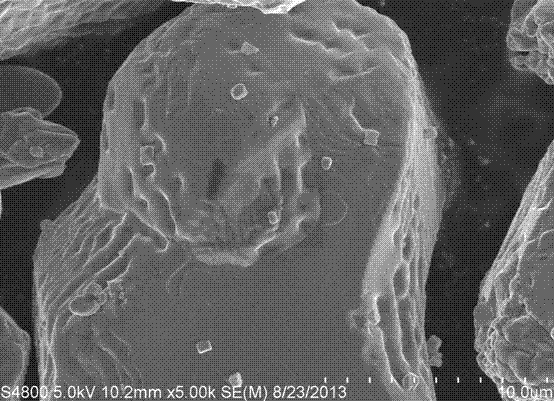

Embodiment 1

[0049] Lithium cobaltate (molecular formula: LiCo) with an average particle size of 18.7 μm 0.994 Ti 0.002 Mg 0.004 o 2 , BET specific surface area 0.167 m 2 / g) 0.5% (mass fraction, the same as in the following examples) of LiNi is first formed on the surface of the core 0.5 mn 0.5 o 2 cladding layer, and then formed 1000ppmLiScO 2 surface layer.

[0050] Its preparation method is as follows: use deionized water to prepare a mixed solution of manganese acetate and nickel acetate with a concentration of 0.05M (manganese: nickel molar ratio = 1:1, called solution A1), and a concentration of 0.1M LiOH solution (called solution A1). solution B1), ammonia solution with a concentration of 0.52M (referred to as solution C1), and scandium nitrate solution with a concentration of 0.015M (referred to as solution D1).

[0051] Dissolve 4g of polyethylene glycol (PEG-6000) in 2000mL of deionized water under stirring, add to the reaction kettle, add 400g of lithium cobaltate with ...

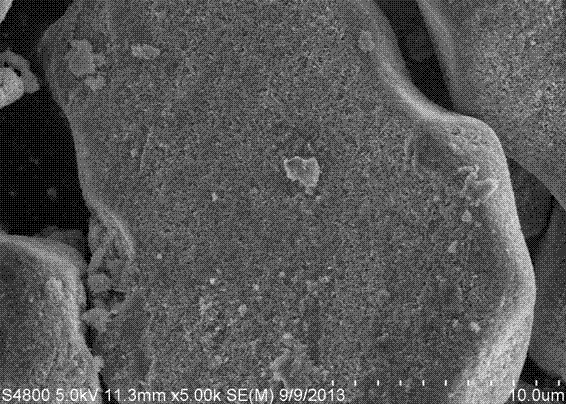

Embodiment 2

[0053] Lithium cobaltate (molecular formula: LiCo) with an average particle size of 18.7 μm 0.994 Ti 0.002 Mg 0.004 o 2 , BET specific surface area 0.167m 2 / g) 2% LiNi is first formed on the surface of the core0.4975 mn 0.4975 Al 0.005 o 2 cladding layer, and then formed 1000ppmLiYO 2 surface layer.

[0054] Its preparation method is as follows: use deionized water to prepare a mixed solution of manganese acetate, nickel acetate and aluminum nitrate with a concentration of 0.2M (manganese: nickel molar ratio = 1:1, called solution A2), and a concentration of 0.4M LiOH solution (referred to as solution B2), ammonia solution with a concentration of 2.0M (referred to as solution C2), and yttrium nitrate solution with a concentration of 0.015M (referred to as solution D2).

[0055] With stirring, 4 g of polyoxyethylene ether C 56 h 114 o 21 Dissolve in 2000mL deionized water, add to the reaction kettle, add 400g of lithium cobalt oxide with an average particle size of...

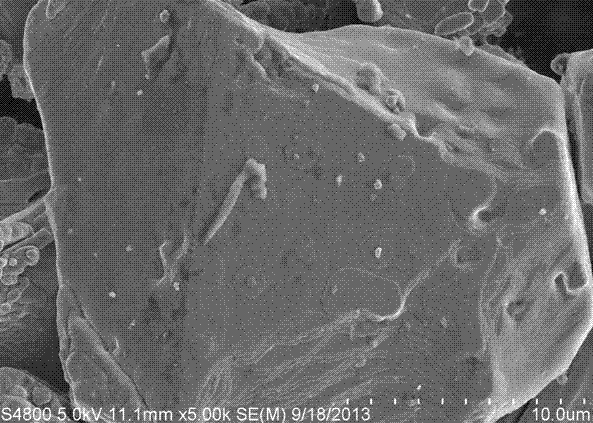

Embodiment 3

[0057] Lithium cobaltate (molecular formula: LiCo) with an average particle size of 18.7 μm 0.994 Ti 0.002 Mg 0.004 o 2 , BET specific surface area 0.167m 2 / g) 5% LiNi is first formed on the core surface 0.5 mn 0.5 o 2 cladding layer, and then formed 2000ppmLiLaO 2 surface layer.

[0058] Its preparation method is as follows: use deionized water to prepare a mixed solution of manganese acetate and nickel acetate with a concentration of 0.5M (manganese: nickel molar ratio = 1:1, called solution A3), and a concentration of 1M LiOH solution (called solution A3). Solution B3), ammonia solution with a concentration of 5.2M (referred to as solution C3), and lanthanum nitrate solution with a concentration of 0.03M (referred to as solution D3).

[0059] Dissolve 4g of polyvinylpyrrolidone (PVP, K-30) in 2000mL of deionized water under stirring, add to the reaction kettle, add 400g of lithium cobaltate with an average particle size of 18.7μm into the reaction kettle, raise the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com