Method for performing microwave solvothermal in-situ synthesis on carbon-coated lithium iron phosphate

A carbon-coated lithium iron phosphate and microwave solvothermal technology, which is applied in electrical components, battery electrodes, circuits, etc., can solve the problems of easy agglomeration of lithium iron phosphate powder, difficulty in obtaining uniform size, and long reaction period, so as to improve the Electrochemical performance, ensuring uniformity, the effect of short reaction cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] 0.01mol LiAc·2H 2 O and 0.01mol Fe(NO 3 ) 3 ·9H 2 O is dispersed in 70mL diethylene glycol, after stirring evenly, slowly add 0.01mol H 3 PO 4 , And constantly stirring, then add 3mL ethylenediamine dropwise, stir evenly to obtain the precursor solution. Take 40 mL of the precursor solution into a 100 mL microwave reactor, and react at 220° C. for 1 h. After cooling to room temperature, the reaction solution is washed with deionized water and ethanol several times and then dried in an oven at 100° C. to obtain the precursor. Put the precursor in a reducing atmosphere (5vol.%H 2 And 95vol.% Ar) was heated to 700°C and calcined for 10 hours. After the furnace is naturally cooled to room temperature, the carbon-coated three-dimensional bi-continuous structure LiFePO is obtained 4 / C.

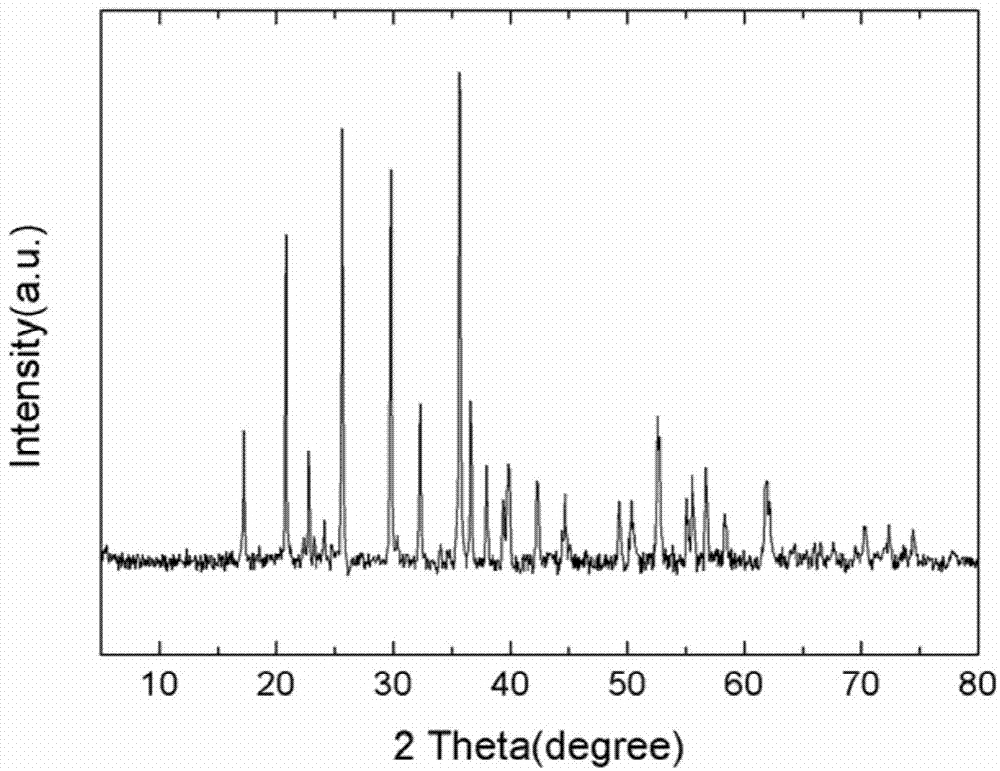

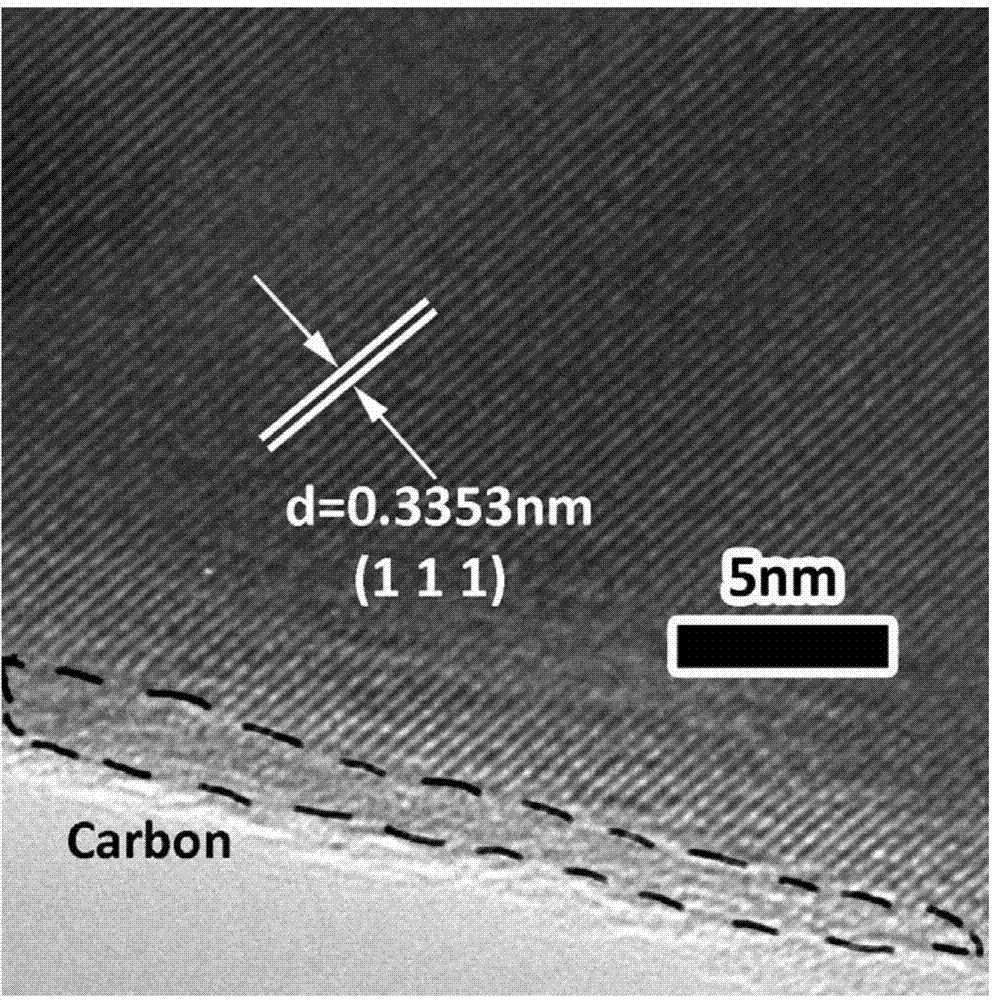

[0040] The carbon-coated lithium iron phosphate prepared by the above method is subjected to powder X-ray diffraction, and its spectrum is as follows figure 1 Shown. by figure 1 It can be seen...

Embodiment 2

[0042] Add 0.005mol LiAc·2H 2 O and 0.005mol Fe(NO 3 ) 3 ·9H 2 Disperse O in 70mL diethylene glycol, stir evenly, slowly add 0.005mol H 3 PO 4 , And keep stirring, then add 3mL ethylenediamine dropwise, stir evenly to obtain the precursor liquid. Take 35mL of the precursor solution into a 100mL microwave reactor and react at 220°C for 1 hour. After cooling to room temperature, the reaction solution is washed with deionized water and ethanol for several times and then dried in an oven at 100°C to obtain the precursor. Put the precursor in a reducing atmosphere (5vol.%H 2 And 95vol.% Ar) was heated to 700°C and calcined for 10 hours. After the furnace is naturally cooled to room temperature, a carbon-coated three-dimensional bi-continuous structure LiFePO is obtained 4 / C.

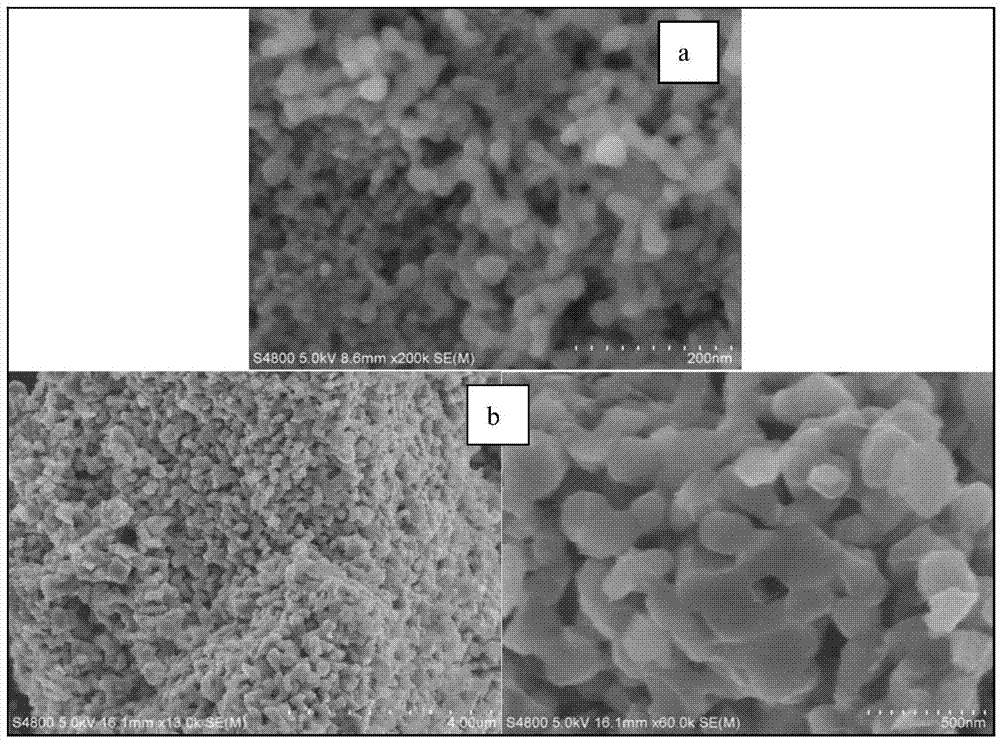

[0043] The scanning electron micrograph (SEM) of the prepared precursor (a) and the calcined product lithium iron phosphate (b) are as follows Figure 4 Shown. by Figure 4 (a) It can be seen that the precurso...

Embodiment 3

[0045] Add 0.005mol LiAc·2H 2 O and 0.005mol Fe(NO 3 ) 3 ·9H 2 O is dispersed in 70mL diethylene glycol, after stirring evenly, slowly add 0.005mol H 3 PO 4 , And keep stirring, then add 3mL ethylenediamine dropwise, stir evenly to obtain the precursor liquid. Take 50 mL of the precursor solution into a 100 mL microwave reactor, and react at 220° C. for 20 min. After cooling to room temperature, the reaction solution was washed with deionized water and ethanol several times and then dried in an oven at 100° C. to obtain the precursor. Put the precursor in a reducing atmosphere (5vol.%H 2 And 95vol.% Ar) was heated to 700°C and calcined for 10 hours. After the furnace is naturally cooled to room temperature, a carbon-coated three-dimensional bi-continuous structure LiFePO is obtained 4 / C.

[0046] The scanning electron micrograph (SEM) of the prepared precursor is shown as Figure 5 Shown. It can be seen from the figure that the precursor is a bi-continuous structure formed by i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com