Voltage cutting method based weak magnet method for low-switch-loss open-winding permanent synchronizing motor system

A permanent magnet synchronous motor and field weakening control technology, applied in motor generator control, electronic commutation motor control, control system and other directions, can solve the problem of low voltage utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0088] In order to describe the present invention more specifically, the technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

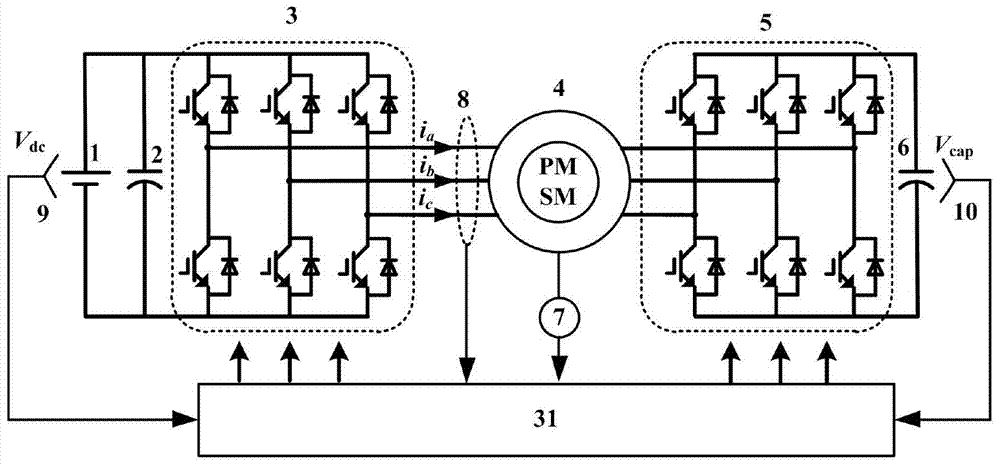

[0089] like figure 1 As shown, the motor system in this example consists of a DC power supply 1, a voltage stabilizing capacitor 2, a main inverter 3, an open-winding permanent magnet synchronous motor 4, a regulating inverter 5, a large capacitor 6, a photoelectric encoder disc 7, and a three-phase current sensor 8. Composed of main inverter DC bus voltage sensor 9 , capacitive voltage sensor 10 and controller 31 . The controller usually adopts DSP (such as TI's TMS320LF2812, etc.).

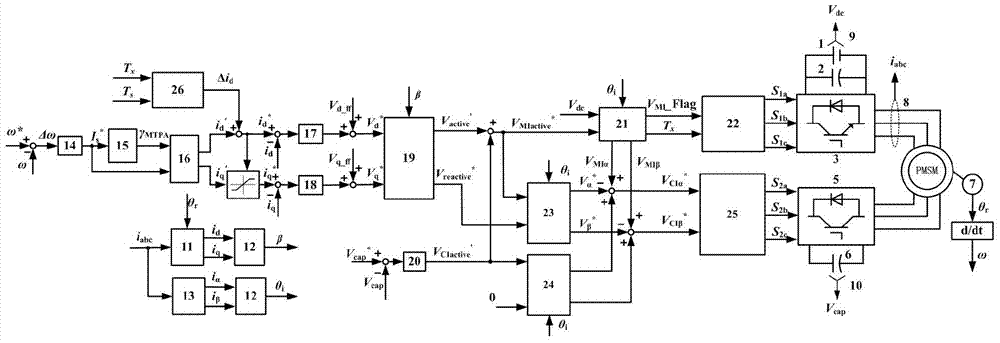

[0090] like figure 2 As shown, the present invention is based on the low switching frequency open-winding permanent magnet synchronous motor control method of the voltage cutting method, comprising the following steps:

[0091] (1) Signal acquisition.

[0092] The roto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com