A kind of preparation method of ternary eutectic ozonation catalyst for wastewater treatment

A technology for ozone oxidation and wastewater treatment, applied in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc., can solve the problem of high cost of precious metals, small specific surface area, and catalyst deactivation and other problems, to achieve high ion conductance effect, make up for lattice defects, and promote the effect of migration and diffusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

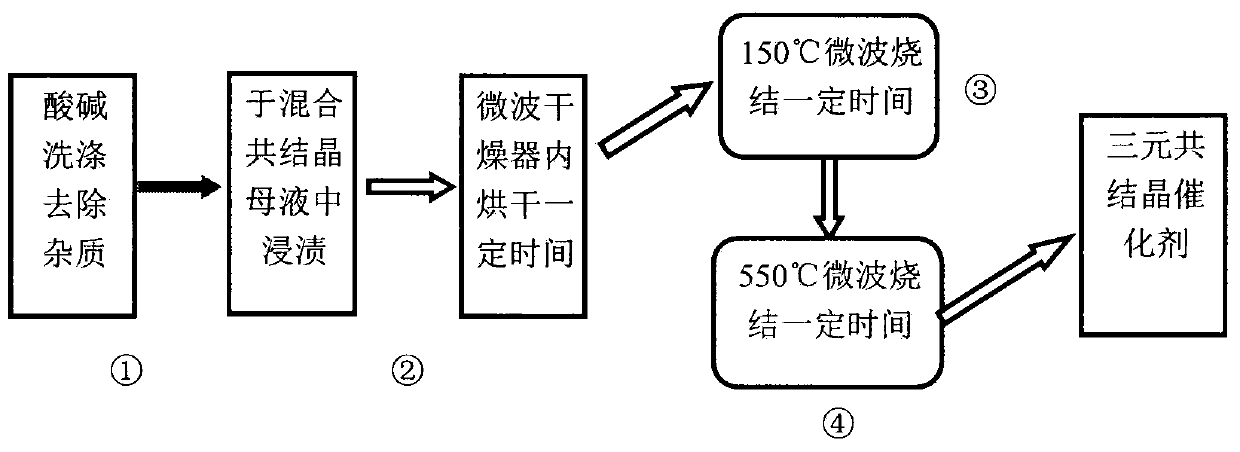

[0030] With a mass ratio of 50% Mn(NO 3 ) 2 solution, Fe(NO 3 ) 3 9H 2 O and Ni(NO 3 ) 2 ·6H 2 O was formulated into a mixed co-crystal leaching mother liquor with a molar concentration ratio of 5:5:1, and 0.04 mol / L of KCl was added to the mother liquor as a co-crystal accelerator. Dry in a microwave drying oven at 120°C, and then pyrolytically oxidize in a microwave high-temperature sintering furnace: the process conditions are: the initial temperature is set to 150°C, sintering at a constant temperature for 1 hour, and then the temperature is quickly increased to 550°C within 20 minutes , sintered for 2 hours, so that the three nitrates are rapidly decomposed and oxidized into co-crystal Fe under the promotion of K ions 5 mn 5 Ni 2 o 17 / Al 2 o 3 .

[0031] A 2-meter-thick fixed bed of the co-crystallization catalyst is added in the HL-HCOS-I advanced oxidation device, and the secondary effluent of coking wastewater is subjected to advanced treatment. Raw wate...

Embodiment 2

[0034] With a mass ratio of 50% Mn(NO 3 ) 2 solution, Fe(NO 3 ) 3 9H 2 O and Ni(NO 3 ) 2 ·6H 2 O was formulated into a mixed co-crystallization mother liquor with a molar concentration ratio of 4:2:1, and 0.02 mol / L of KCl was added to the aqueous solution as a co-crystallization accelerator. Dry in a microwave drying oven at 120 degrees for 1 hour, and then decompose and oxidize it in a microwave high-temperature sintering furnace. Raise it to 550°C and sinter for 2 hours, so that the three nitrates can be rapidly decomposed and oxidized into co-crystal Fe under the promotion of K ions 2 MnNiO 6 / Al 2 o 3 .

[0035] A 2-meter-thick fixed bed of the co-crystallization catalyst is added to the HL-HCOS-I advanced oxidation device to perform advanced treatment on the secondary effluent of landfill leachate. Raw water COD is 200mg / L. The effective volume of the catalytic reactor is 500L, and the rated output of the ozone generator is 25g / h through micron aeration of o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com