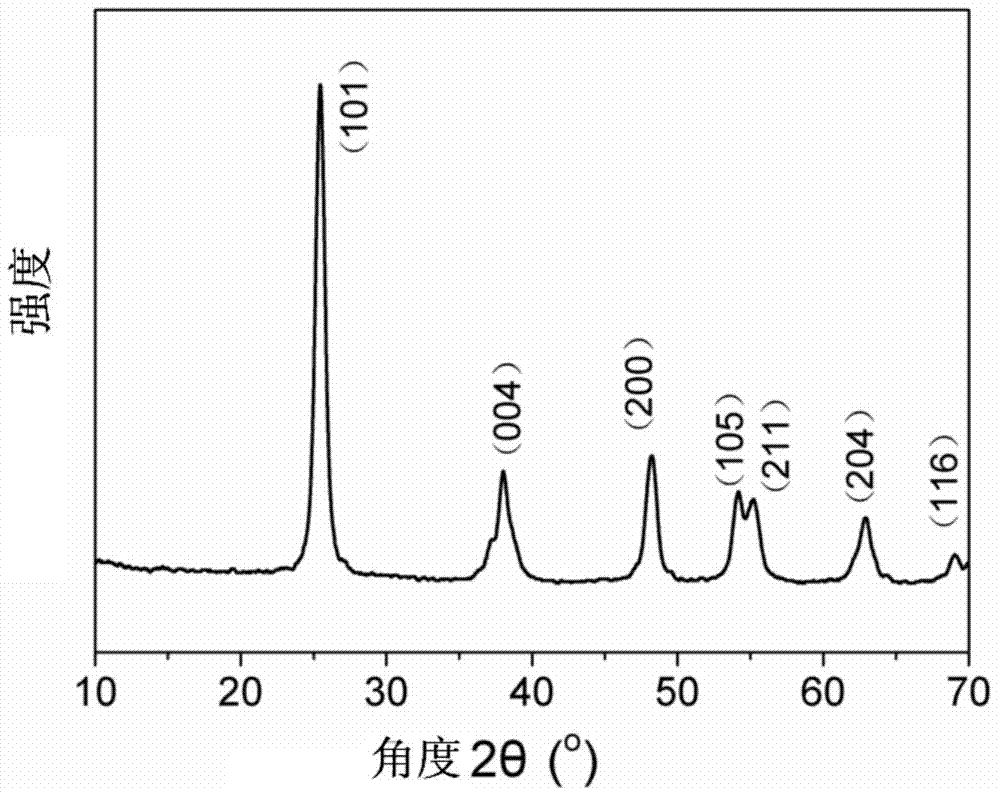

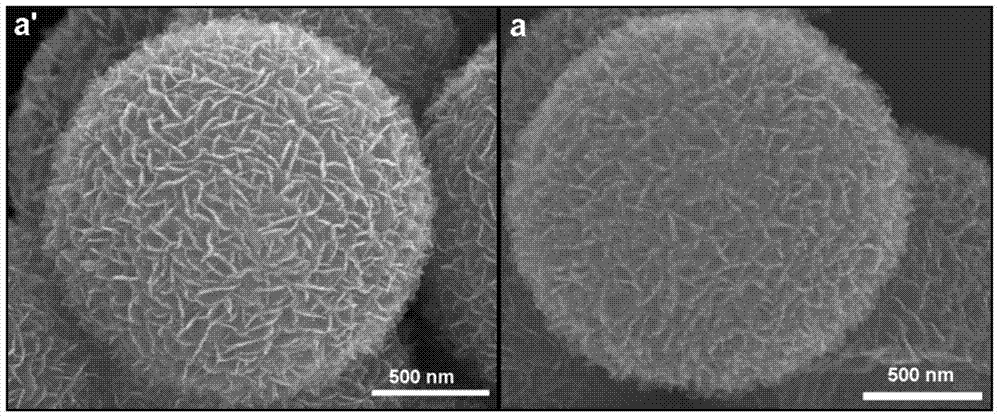

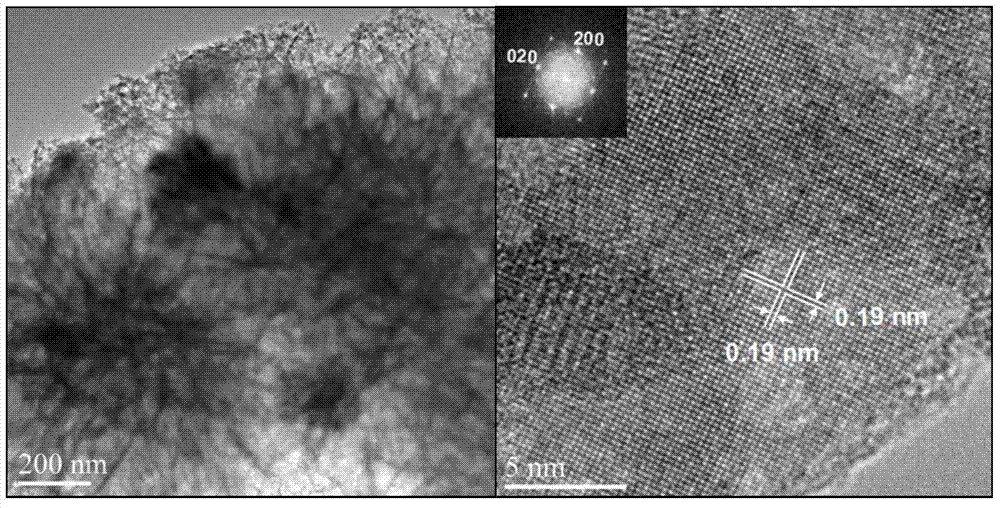

Nitrogen-doped anatase TiO2 nano-sheet multilevel ball and preparation method thereof

A technology of nano-sheets and anatase, applied in the field of nitrogen-doped anatase TiO2 nano-sheet multi-level spheres and its preparation, can solve the problems of reaction system toxicity, easy pollution of the environment, strong corrosion, etc., and achieve green operation Environmental protection, high repeatability and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Step 1: Accurately measure 71mL of isopropanol solvent into a self-generating pressure reactor, add 0.09mL of morphology control agent diethylenetriamine and 4.50mL (0.0134mol) of isopropyl titanate solution in sequence, and stir gently for 1min to evenly disperse. Add accurately weighed 0.0492g (0.00164mol) urea to the above mixture, stir slowly for 1min and then ultrasonically disperse for 5min;

[0033] Step 2: Seal the reaction kettle containing the reaction mixture and place it in an oven at 200° C. to crystallize the solution in the high-pressure reaction kettle for 24 hours under self-generated pressure. Naturally cool to room temperature after crystallization, centrifuge the light yellow slurry, wash the precipitate with absolute ethanol 4 times and dry at 60°C for 12 hours to obtain a light yellow precursor, which is denoted as 0.12N-{001}TiO 2 -24, wherein 0.12 is the nominal molar ratio of nitrogen atom and titanium atom; 24 is crystallization time;

[0034...

Embodiment 2

[0038] Step 1: Accurately measure 71mL of isopropanol as a solvent in a self-generating pressure reactor, add 0.09mL of morphology control agent diethylenetriamine and 4.50mL (0.0134mol) of isopropyl titanate solution in sequence, and stir gently 1min to evenly disperse. Add accurately weighed 0.12g (0.0041mol) urea to the above mixture, stir slowly for 1min and then ultrasonically disperse for 5min;

[0039] Step 2: Seal the reaction kettle containing the reaction mixture and place it in an oven at 200° C. to crystallize the solution in the high-pressure reaction kettle for 24 hours under self-generated pressure. Naturally cool to room temperature after crystallization, centrifuge the light yellow slurry, wash the precipitate with absolute ethanol 4 times and dry at 60°C for 12 hours to obtain a light yellow multi-level structure precursor, denoted as 0.3N-{001}TiO 2 -24, wherein 0.3 is the nominal molar ratio of nitrogen atom and titanium atom; 24 is the crystallization tim...

Embodiment 3

[0042] Step 1: Accurately measure 71mL of isopropanol as a solvent in a self-generating pressure reactor, add 0.09mL of morphology control agent diethylenetriamine and 4.50mL (0.0134mol) of isopropyl titanate solution in sequence, and stir gently 1min to evenly disperse. Add accurately weighed 0.4920g (0.0164mol) urea to the above mixture, stir slowly for 1min and then ultrasonically disperse for 5min;

[0043] Step 2: Seal the reaction kettle containing the reaction mixture and place it in an oven at 200° C. to crystallize the solution in the high-pressure reaction kettle for 24 hours under self-generated pressure. Naturally cool to room temperature after crystallization, centrifuge the light yellow slurry, wash the reaction precipitate 4 times with absolute ethanol and dry at 60°C for 12 hours to obtain a light yellow multi-level structure precursor, which is denoted as 1.2N-{001}TiO 2 -24, wherein 1.2 is the nominal molar ratio of nitrogen atom and titanium atom; 24 is cry...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com