Treatment apparatus and treatment method for wastewater produced during fumaric acid generation process

A technology of generation process and treatment method, applied in natural water body treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. The evaporation chamber is easy to block and other problems, so as to achieve the effect of small footprint, low operating cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the examples, but the protection scope of the present invention is not limited only to the examples.

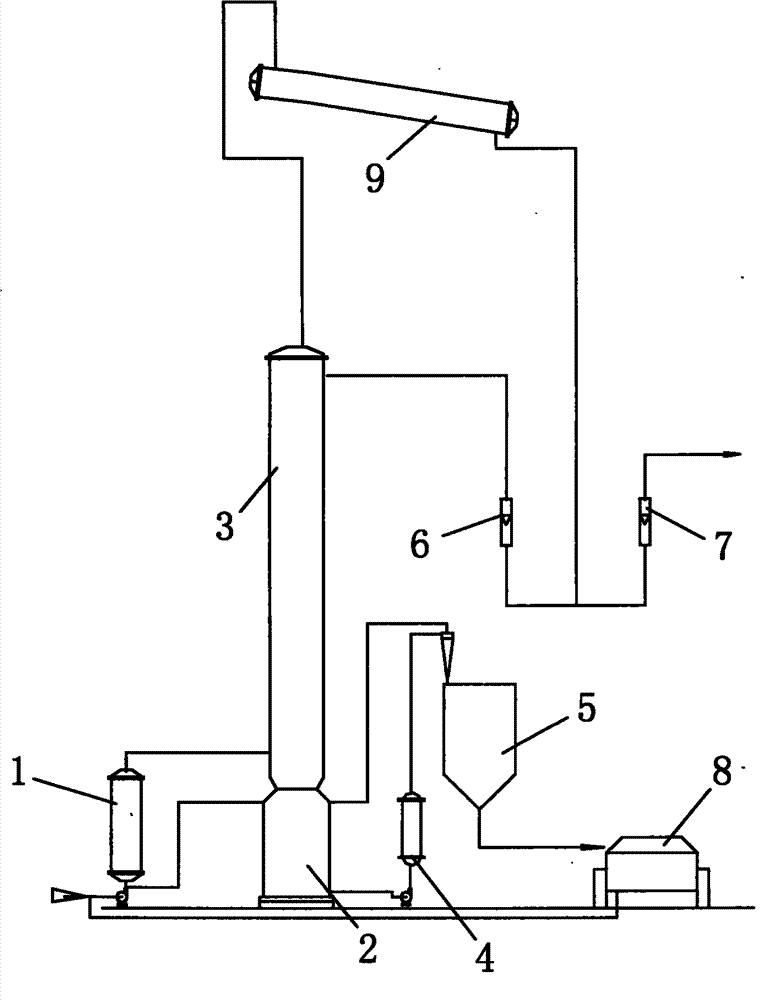

[0025] like figure 1 As shown, a treatment device for waste water generated during the production of fumaric acid, including a heating chamber 1, a crystallizer 2, a rectification tower 3, a cooler 4, a crystallization receiving tank 5, a reflux flow meter 6, and a distillate flow rate Meter 7, centrifuge 8 and condenser 9.

[0026] The top of the heating chamber 1 is connected to the lower side of the rectification tower 3, the bottom of the heating chamber 1 is connected to the upper side of the crystallizer 2, the bottom of the rectification tower 3 is connected to the top of the crystallizer 2, and the top of the rectification tower 3 is connected to the top of the crystallizer 2. The upper end of the condenser 9 is connected, the lower end of the condenser 9 is connected with the reflux flo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com