A novel anti-corrosion nanocomposite coating and its preparation method

A nano-composite, anti-corrosion technology, applied in the field of coatings, to achieve strong adhesion, avoid economic losses, and eliminate direct contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

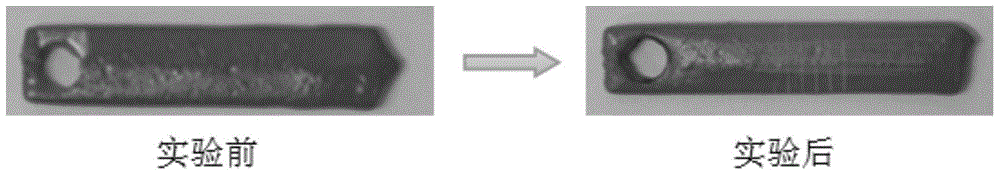

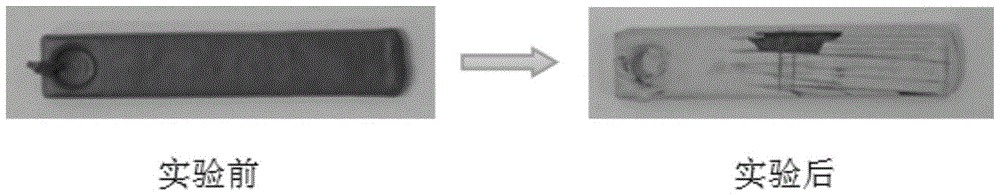

Image

Examples

Embodiment 1

[0026] A novel anti-corrosion nano-composite coating in this embodiment is made up of the following raw materials in mass percentage: 35% modified resin, 15% glass flakes, a mixture of 30% xylene and cyclohexanone, 3% talcum powder, 5% phosphoric acid Zinc, 2% bentonite, 5% dibutyl phthalate, 3% p-hydroxybenzenesulfonic acid and 2% nanoscale titanium dioxide. Among them, the modified resin is epoxy-modified phenolic resin. The phenolic resin is mainly modified by mechanical mixing method to achieve interpenetration at the molecular level, thereby forming an interpenetrating network (IPN) structure and producing a synergistic effect.

[0027] Prepare the corrosion-resistant nanocomposite coating of the present embodiment, comprise the steps:

[0028] Step 1: using a mechanical mixing method to modify the phenolic resin to obtain a modified resin;

[0029] Step 2: mixing and stirring xylene and cyclohexanone according to the mass percentage of 60%: 40%, to obtain a mixture of x...

Embodiment 2

[0037] A novel anti-corrosion nanocomposite paint and preparation method thereof, made of the following raw materials in mass percentage: 25% novel modified resin, 13% glass flakes, 40% xylene and cyclohexanone mixture, 4% talcum powder, 6% Zinc Phosphate, 1% Bentonite Clay, 6% Dibutyl Phthalate, 2% P-Hydroxybenzene Sulfonic Acid and 3% Nanoscale Titanium Dioxide. Among them, the modified resin is polyamide modified phenolic resin, and the phenolic resin is mainly modified by the copolymerization method to realize interpenetration at the molecular level, thereby forming an interpenetrating network (IPN) structure and producing a synergistic effect.

Embodiment 3

[0039] A novel anti-corrosion nanocomposite paint and preparation method thereof, made of the following raw materials in mass percentage: 28% novel modified resin, 14% glass flakes, 35% mixture of xylene and cyclohexanone, 3% talcum powder, 8% Zinc Phosphate, 2% Bentonite Clay, 5% Dibutyl Phthalate, 3% Paraben Sulfonic Acid, and 2% Nanoscale Titanium Dioxide. Among them, the new modified resin is polyamide modified phenolic resin, which is mainly modified by copolymerization method to realize interpenetration at the molecular level, thereby forming an interpenetrating network (IPN) structure and generating synergistic effects.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com