Ultrafine grained invar alloy ribbon and preparation method thereof

An Invar alloy and ultra-fine-grained technology, which is applied in the field of ultra-fine-grained Invar alloy thin strips and its preparation, can solve the problem of low driving force, environmental pollution, and the inability to simultaneously achieve low-cost and uniform ultra-fine-grained Invar alloys Solve problems such as thin strip preparation methods to achieve the effect of uniform size and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1: The ultrafine-grained Invar alloy thin strip is prepared by the following method.

[0031] (1) Smelting process: According to the alloy composition described in Table 1, put the raw materials into the vacuum induction melting furnace, and vacuumize to 0.5×10 -3 Pa, gradually increase the magnetic field strength of the induction coil, heat the raw material to 1550 ° C, completely melt into molten steel, and then smelt for 5 minutes, fill it with argon, and start casting.

[0032] (2) Casting process: pour the molten steel into the sand mold; after the molten steel is completely cooled, the mold is demoulded, and the sand particles embedded in the surface of the ingot are removed with a milling machine.

[0033] (3) Solution treatment process: Put the surface-treated Invar alloy ingot into a medium-frequency induction heating furnace, raise the temperature to 1250°C, and keep it for 1 hour.

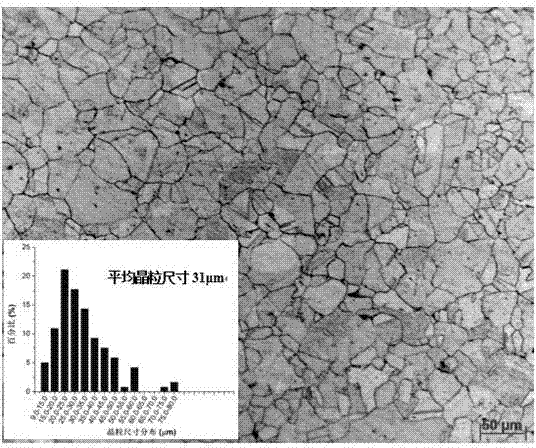

[0034] (4) Hot rolling process: the ingot is then subjected to bl...

Embodiment 2

[0037] Embodiment 2: The ultrafine-grained Invar alloy thin strip is prepared by the following method.

[0038] The process parameters in the preparation process of this embodiment are the same as those in Example 1.

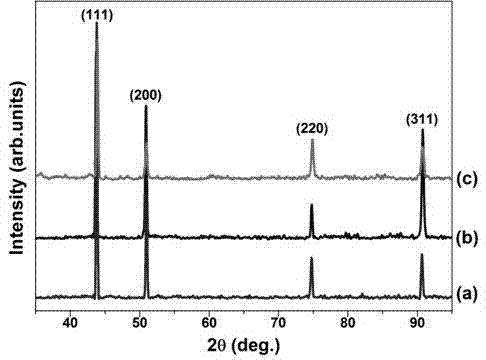

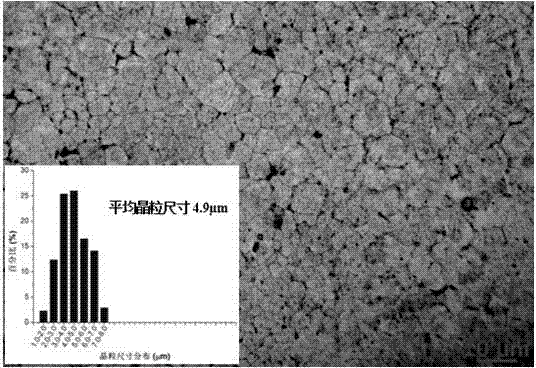

[0039] The average grain size of the ultrafine-grained Invar alloy thin strip obtained in this embodiment is 5.0 μm, the thickness of the thin strip is 40 μm, the width is 3.3 mm, and the coefficient of thermal expansion α -100~100℃ =1.4×10 -6 / o C, the hardness value is 201Hv.

Embodiment 3

[0040] Embodiment 3: The ultrafine-grained Invar alloy thin strip is prepared by the following method.

[0041] The process parameters in the preparation process of this embodiment are the same as those in Example 1.

[0042] The average grain size of the ultrafine-grained Invar thin strip obtained in this embodiment is 4.8 μm, the thickness of the thin strip is 37 μm, the width is 3.5 mm, and the coefficient of thermal expansion α -100~100℃ =1.2×10 -6 / o C, the hardness value is 198Hv.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com