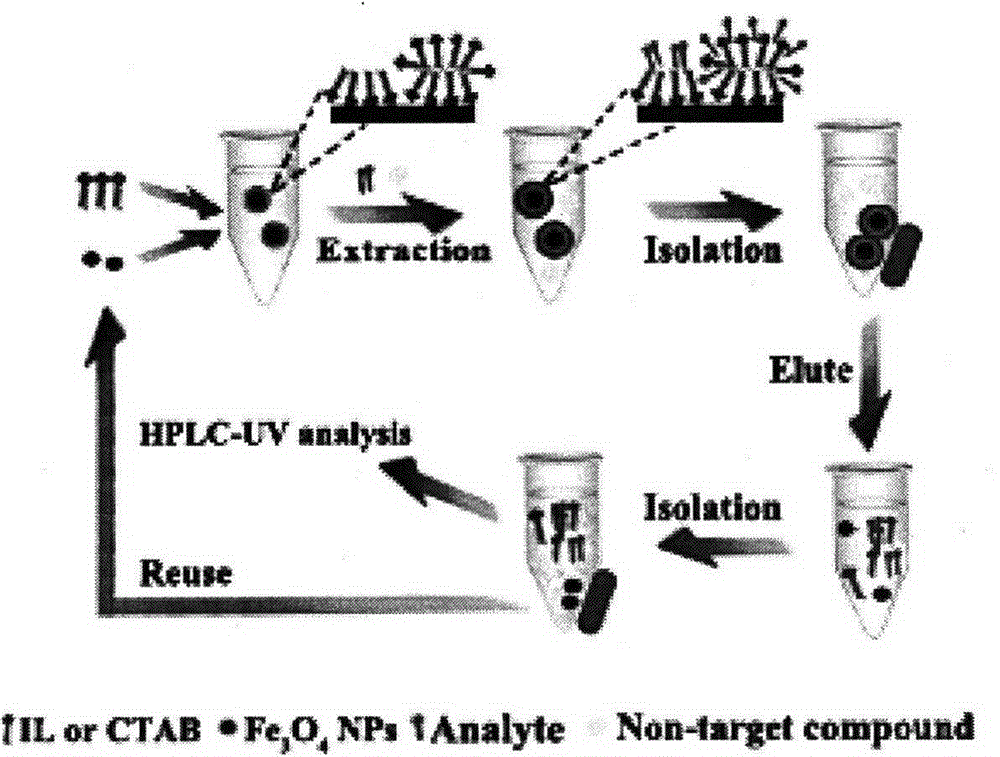

Preparation method of mixed hemi-micelle solid phase extractant based on Fe3O4 magnetic nanoparticles

A technology of magnetic nanoparticles and solid-phase extraction agents, applied in chemical instruments and methods, silicon compounds, alkali metal compounds, etc., can solve the problems of large particles, time-consuming operation, and high consumption of adsorbents, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

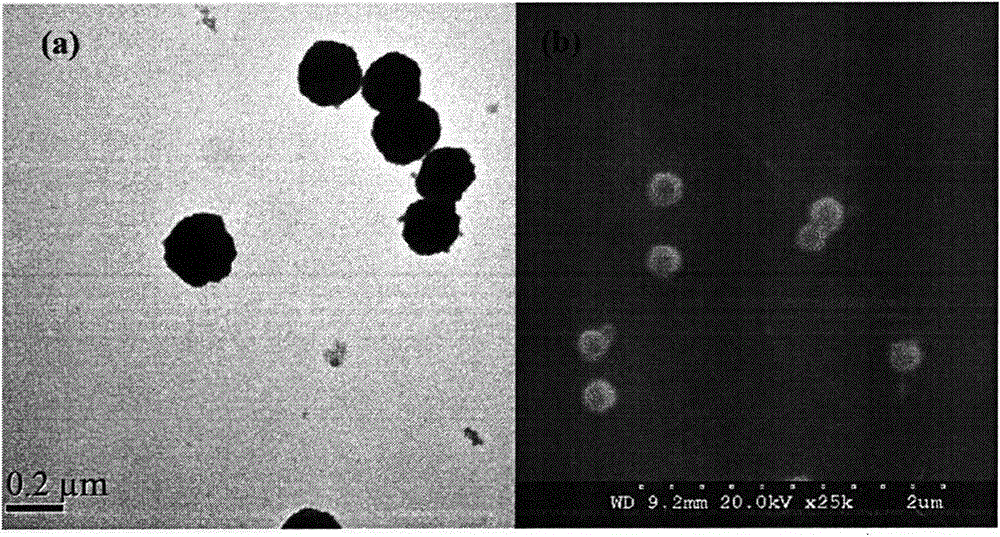

[0027] Add 2.4g of ferric chloride, 3.4g of sodium acetate and 3.4g of sodium acrylate into a mixed solvent consisting of 33.75ml of ethylene glycol and 11.25ml of diethylene glycol, and ultrasonically obtain a black mixed solution for 1 hour, which is transferred to a poly In a reaction kettle made of tetrafluoroethylene, seal it, place it in a muffle furnace to react for 10 hours, cool to room temperature after the reaction, wash with methanol and water several times, vacuum dry at 60°C to constant weight, and set aside;

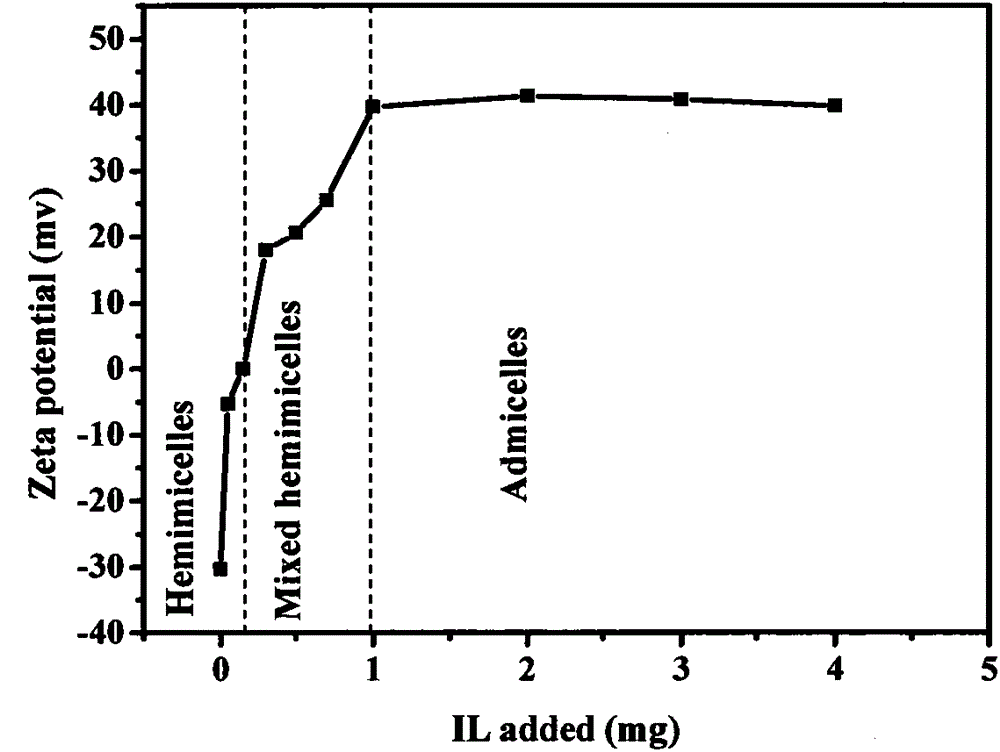

[0028] 4.0mg of the above-prepared Fe 3 o 4 Magnetic nanoparticles, 1.0mg cetyltrimethylammonium bromide (CTAB) and 2ml 0.02M sodium phosphate buffer solution with pH = 7.0 were sequentially added to the plastic tube, the mixture was ultrasonically dispersed for 5 minutes, and then balanced for 10 minutes. Afterwards, an external magnetic field was placed on the side wall of the plastic tube to separate the magnetic particles. After 2 seconds, the supernata...

Embodiment 2

[0030] Add 2.4g of ferric chloride, 3.4g of sodium acetate and 3.4g of sodium acrylate into a mixed solvent consisting of 33.75ml of ethylene glycol and 11.25ml of diethylene glycol, and ultrasonically obtain a black mixed solution for 1 hour, which is transferred to a poly In a reaction kettle made of tetrafluoroethylene, seal it, place it in a muffle furnace to react for 10 hours, cool to room temperature after the reaction, wash with methanol and water several times, vacuum dry at 60°C to constant weight, and set aside;

[0031] 4.0mg of the above-prepared Fe 3 o 4 Magnetic nanoparticles, 3.0 mg 1-dodecyl-3-methylimidazole chloride (C 12 mimCl) and 2m10.02M potassium phosphate buffer solution with pH=7.0 were sequentially added into the plastic tube, the mixed solution was ultrasonically dispersed for 5min, then equilibrated and left for 10min, and then an external magnetic field was placed on the side wall of the plastic tube to separate the magnetic particles. After 2s, ...

Embodiment 3

[0033] Add 2.4g of ferric chloride, 3.4g of sodium acetate and 3.4g of sodium acrylate into a mixed solvent consisting of 33.75ml of ethylene glycol and 11.25ml of diethylene glycol, and ultrasonically obtain a black mixed solution for 1 hour, which is transferred to a poly In a reaction kettle made of tetrafluoroethylene, seal it, place it in a muffle furnace to react for 10 hours, cool to room temperature after the reaction, wash with methanol and water several times, vacuum dry at 60°C to constant weight, and set aside;

[0034] 1.0g Fe 3 o 4 Add magnetic nanoparticles to 150mL ethanol and 25mL deionized water, ultrasonicate for 5min, then add 2mL ammonia water and 5mL tetraethyl orthosilicate in sequence, and react for 6h under stirring. After the reaction, add an external magnetic field to separate the product, wash with methanol and water several times , vacuum-dried at 60°C to constant weight, and set aside.

[0035] 4.0mg of the above-prepared Fe 3 o 4 SiO 2 Magne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com