Preparation method of nano-lanthanum strontium manganese oxide/graphene composite wave absorbing coating

A graphene composite, lanthanum strontium manganese oxide technology, applied in coatings, epoxy resin coatings, radiation-absorbing coatings, etc., can solve problems such as thick metal graphene composite coatings, and achieve wave-absorbing frequency bandwidth and system structure Simple, fast processing results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

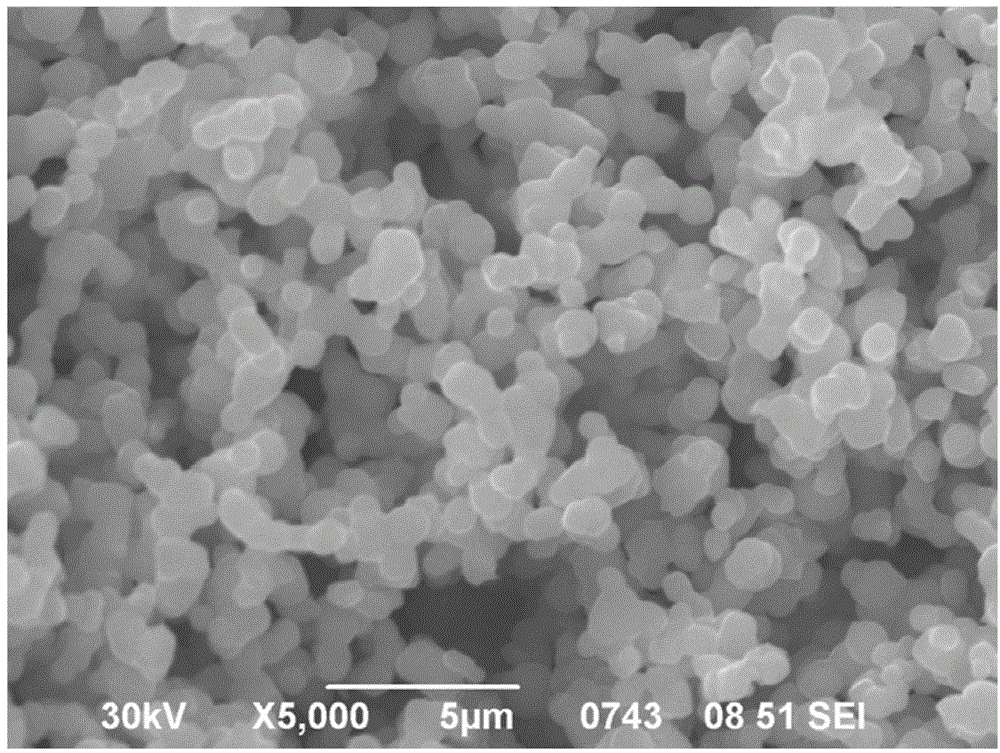

[0029] Example 1: Preparation of metal-based nano-lanthanum strontium manganese oxide / graphene composite absorbing coating by spin coating method

[0030] (1) Use lanthanum nitrate, strontium nitrate, and manganese nitrate in molar ratios of 0.7:0.3:1, respectively, add citric acid, and use sol-gel self-combustion method to prepare lanthanum strontium manganese oxide nanopowder with a particle size of 1-100nm. Add graphene, epoxy resin dissolved in absolute ethanol and curing agent to prepare slurry.

[0031](2) The substrate is made of an aluminum plate, which is ultrasonically cleaned, dried, and then fixed on a spin coater;

[0032] (3) Drop the prepared slurry onto the substrate, start it at a low speed, and spread the spin coating solution evenly into a thin film. Place it at room temperature to dry it naturally, then put it in a vacuum drying oven to dry for 10 hours, and then coat the film again. Finally, put it into a vacuum drying oven to dry. Put the coated film int...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com