Organosilicone heat conduction insulating piece and preparation method thereof

A technology of heat conduction insulation and heat conduction insulation layer, which is applied in the field of organic silicon heat conduction insulation sheet and its preparation, which can solve the problems of inability to further improve the heat conduction performance, poor tear resistance of the sheet, and low filler filling rate, etc., and achieve good insulation performance , good puncture resistance, simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

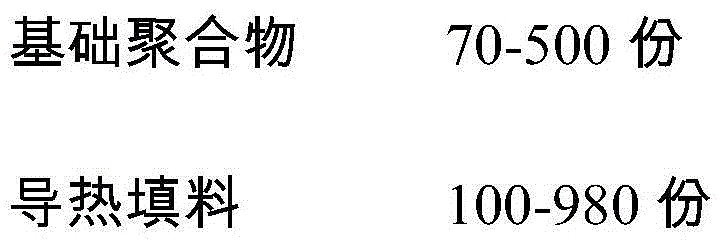

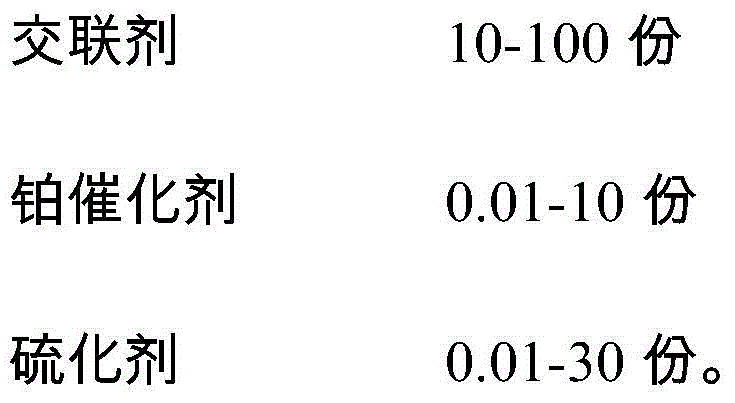

Method used

Image

Examples

preparation example Construction

[0074] The preparation method of the above-mentioned organosilicon heat-conducting insulating sheet comprises the following steps:

[0075] A. Mix the components contained in the silicone thermally conductive and insulating composition uniformly according to the proportion to obtain a mixture;

[0076] B. Form the mixture and cure it at 40-90°C to obtain a cured sheet;

[0077] C. Raise the temperature to 110-250° C. to vulcanize the primary cured sheet to obtain a silicone heat-conducting insulating sheet.

[0078] The molding of the mixture means that the mixture is made into a sheet with a certain thickness by calendering, casting, molding, injection molding, extrusion molding and other techniques.

[0079] Preferably, when the silicone heat-conducting insulating sheet further includes a base material, in step B, the mixture is molded and compounded with the base material, and then cured.

[0080] Preferably, the curing time is the time required for the mixture to cure un...

Embodiment 1

[0091] In the silicone heat-conducting insulating composition, the base polymer is α, ω-divinylpolydimethylsiloxane (the mass percentage of vinyl is 2.5%) with a viscosity of 100mpa·s at 25°C; the heat-conducting filler is Alumina with an average particle size of 30 μm; the crosslinking agent is methyl hydrogen-containing silicone oil with a viscosity of 100 mpa s at 25 °C and a hydrogen content of 0.2% (mass); the chain extender is α , ω-dihydropolydimethylsiloxane (hydrogen content of 0.18% (mass)). The vinyl group in the base polymer (-CH=CH 2 The ratio of the molar weight of ) to the sum of the molar weights of hydrogen groups in the crosslinking agent and chain extender is 2.87.

[0092] In the silicone heat-conducting insulating composition, the silicone resin is DY-MQ102, Shandong Dayi Chemical Co., Ltd. Meanwhile, the platinum catalyst is a platinum catalyst, and the vulcanizing agent is bis(2,4-dichlorobenzoyl) peroxide.

[0093] The preparation method of organosil...

Embodiment 2

[0097] In the silicone heat-conducting and insulating composition, the base polymer is α, ω-divinylpolydimethylsiloxane (the mass percentage of vinyl is 0.50%) with a viscosity of 4000mpa·s at 25°C; the heat-conducting filler is Aluminum nitride with an average particle size of 20 μm; the cross-linking agent is methyl hydrogen-containing silicone oil, the viscosity at 25°C is 1000mpa·s, and the hydrogen content is 0.08% (mass); α,ω-Dihydropolydimethylsiloxane (hydrogen content: 0.05% by mass). The vinyl group in the base polymer (-CH=CH 2 ) and the ratio of the sum of the molar weights of the hydrogen groups in the cross-linking agent and the chain extender is 1.27.

[0098] In the silicone heat-conducting insulating composition, the silicone resin is DY-MQ102, Shandong Dayi Chemical Co., Ltd. Meanwhile, the platinum catalyst is a platinum catalyst, and the vulcanizing agent is bis(2,4-dichlorobenzoyl) peroxide.

[0099] The preparation method of organosilicon heat conducti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com