Rear wall protection method for taking ice-carbon powder mixer as turbine blade for laser processing

A turbine blade and laser processing technology, which is applied to turbines, metal processing, laser welding equipment and other directions, can solve the problems of complex preparation process, high cost, easy agglomeration of nanoparticles, etc., and achieves easy filling process, low cost and simple preparation process. easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

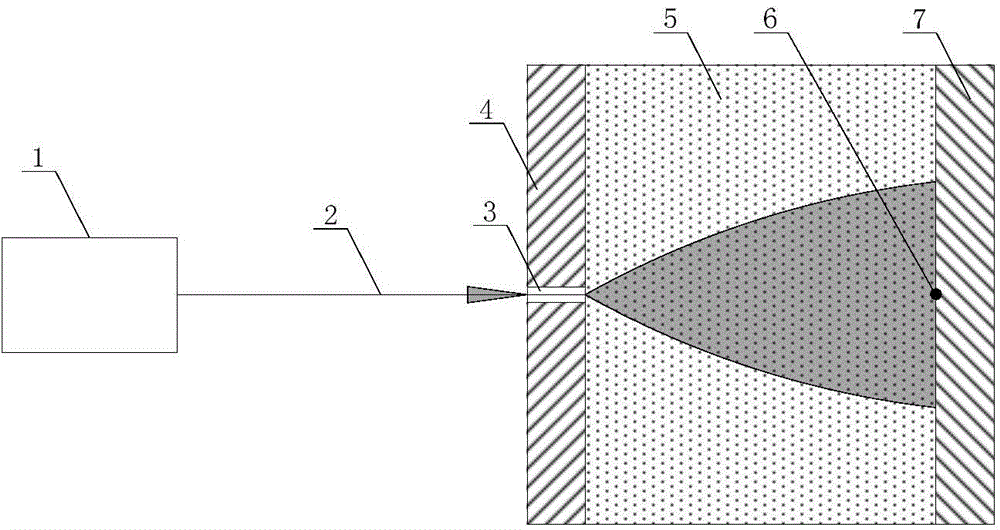

[0022] Using ice-carbon powder mixture as a back wall protection method for laser machining of turbine blades includes the following steps:

[0023] 1) mixing carbon powder particles with a particle size range of 1-6 μm and water to prepare a carbon-water suspension with a mass fraction of carbon of 62%;

[0024] 2) Plug the hole at the bottom of the turbine blade with a rubber stopper, then pour the carbon-water suspension into the blade flow channel through the hole at the top of the turbine blade until it is full;

[0025] 3) Place the turbine blades filled with the carbon-water suspension in a freezer at a temperature of -12°C to freeze. After the water in the carbon-water suspension of the turbine blades freezes into ice, the filling of the protective material is completed;

[0026] 4) Place the turbine blade in an environment of -3°C, and use pulsed laser irradiation to drill holes. The process parameters of pulsed laser drilling are: frequency 70Hz, pulse width 0.2ms, p...

Embodiment 2

[0030] Using ice-carbon powder mixture as a back wall protection method for laser machining of turbine blades includes the following steps:

[0031] 1) mixing carbon powder particles with a particle size range of 9-17 μm and water to prepare a carbon-water suspension with a mass fraction of carbon of 3%;

[0032] 2) Plug the hole at the bottom of the turbine blade with a rubber stopper, then pour the carbon-water suspension into the blade flow channel through the hole at the top of the turbine blade until it is full;

[0033] 3) Place the turbine blades filled with the carbon-water suspension in a freezer at -3°C to freeze. After the water in the carbon-water suspension of the turbine blades freezes into ice, the filling of the protective material is completed;

[0034] 4) Place the turbine blade in an environment less than 0°C, and use pulsed laser irradiation to drill holes. The process parameters of pulsed laser drilling are: frequency 70Hz, pulse width 0.2ms, peak power 16...

Embodiment 3

[0038] Using ice-carbon powder mixture as a back wall protection method for laser machining of turbine blades includes the following steps:

[0039] 1) mixing carbon powder particles with a particle size range of 5-10 μm and water to prepare a carbon-water suspension with a mass fraction of carbon of 20%;

[0040] 2) Plug the hole at the bottom of the turbine blade with a rubber stopper, then pour the carbon-water suspension into the blade flow channel through the hole at the top of the turbine blade until it is full;

[0041] 3) Place the turbine blades filled with the carbon-water suspension in a freezer at -8°C to freeze. After the water in the carbon-water suspension of the turbine blades freezes into ice, the filling of the protective material is completed;

[0042] 4) Place the turbine blade in an environment of -4°C, and use pulsed laser irradiation to drill holes. The process parameters of pulsed laser drilling are: frequency 70Hz, pulse width 0.2ms, peak power 16KW; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com