Method for separation and utilization of fly ash aluminum-silicon, and tobermorite and silicon oxide obtained through method

A technology for separation of tobermorite and aluminum silicon, which is applied in the direction of silicon oxide, silicon dioxide, calcium/strontium/barium chloride, etc., can solve the problem of low added value of aluminum extraction from fly ash, and achieve the goal of increasing added value Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

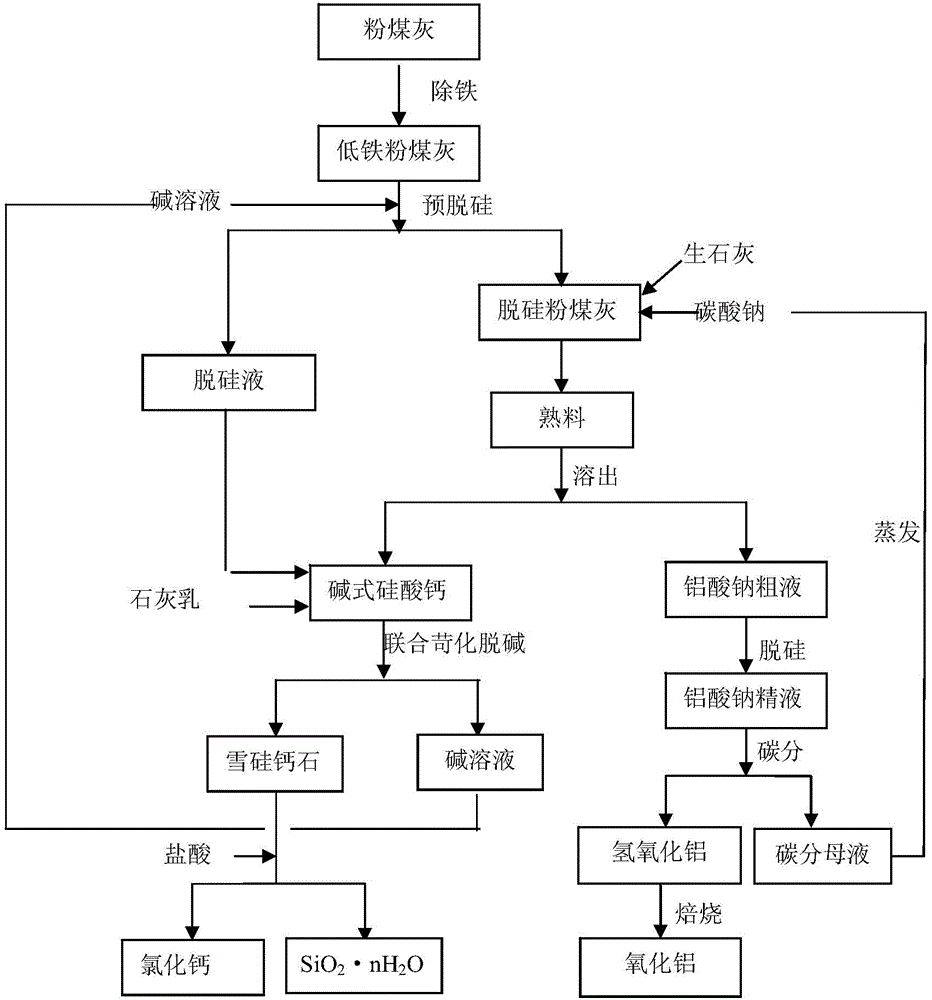

[0059] This example is used to illustrate the method for the separation and utilization of aluminum and silicon in fly ash of the present invention.

[0060] (1) Grind fly ash to 250 mesh, remove iron by magnetic separation, contact with 15% by weight sodium hydroxide solution according to liquid-solid ratio 3:1, react at 110°C for 1 hour, and then separate solid-liquid to obtain sodium silicate desilication liquid and desiliconized fly ash;

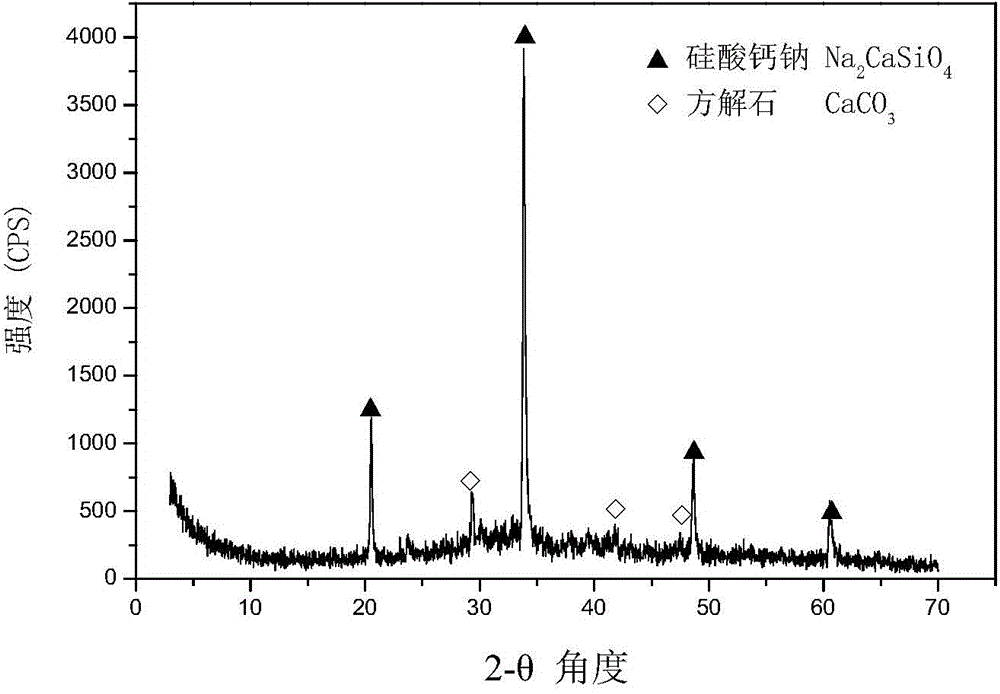

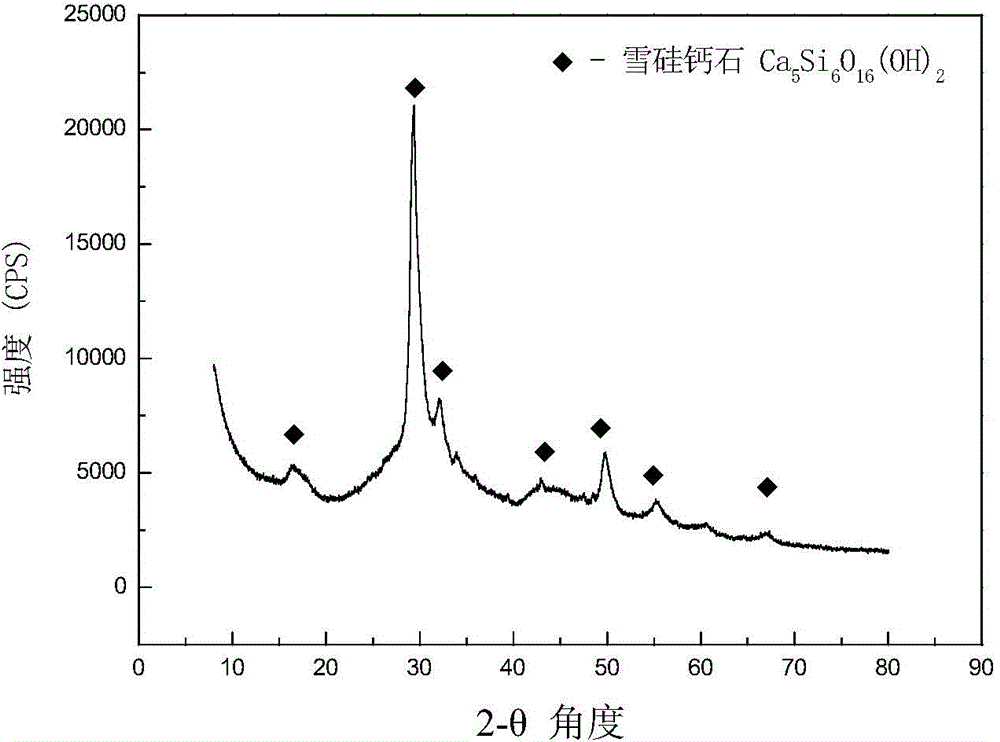

[0061] (2) Mix the desiliconized fly ash obtained in step (1) with quicklime and sodium carbonate according to the weight ratio of 1:0.2:1.10 and sinter at 1150°C for 1 hour to obtain clinker. After grinding the clinker to 80 mesh, The adjusting solution is dissolved at 80°C according to the liquid-solid volume ratio of 4:1 to obtain crude sodium aluminate solution and basic calcium silicate. The XRD pattern of basic calcium silicate is shown in figure 2 , Carry out chemical composition analysis to basic calcium silicate, analysis resu...

Embodiment 2

[0066] This example is used to illustrate the method for the separation and utilization of aluminum and silicon in fly ash of the present invention.

[0067] (1) Grind fly ash to 200 mesh, remove iron by magnetic separation, contact with 10% by weight sodium hydroxide solution according to the liquid-solid ratio of 4:1, react at 90°C for 2 hours, and then separate solid-liquid to obtain sodium silicate desilication liquid and desiliconized fly ash;

[0068] (2) Mix the desiliconized fly ash obtained in step (1) with quicklime and sodium carbonate according to the weight ratio of 1:0.25:1.20 and sinter at 950°C for 2 hours to obtain clinker. After the clinker is ground to 50 mesh, The adjusting solution was dissolved at 70°C according to the liquid-solid volume ratio of 3:1 to obtain the crude sodium aluminate solution and basic calcium silicate. The XRD pattern of basic calcium silicate and figure 2 Similar, not listed, the chemical composition analysis of basic calcium sili...

Embodiment 3

[0073] This example is used to illustrate the method for the separation and utilization of aluminum and silicon in fly ash of the present invention.

[0074] (1) Grind the fly ash to 300 mesh, and after removing iron by magnetic separation, contact with 20% by weight sodium hydroxide solution according to the liquid-solid ratio of 5:1, react at 140°C for 0.5h, and then separate the solid and liquid to obtain the sodium silicate Silicon liquid and desiliconized fly ash;

[0075] (2) Mix the desiliconized fly ash obtained in step (1) with quicklime and sodium carbonate at a weight ratio of 1:0.30:1.20 and sinter at 1250°C for 0.5h to obtain clinker, which is ground to 100 mesh, The adjusted solution was dissolved at 90°C according to the liquid-solid volume ratio of 6:1 to obtain crude sodium aluminate solution and basic calcium silicate. The XRD pattern of basic calcium silicate and figure 2 Similar, not listed, the chemical composition analysis of basic calcium silicate is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com