Electric-insulation thermoplastic resin composition and preparation method thereof

A thermoplastic resin and electrical insulation technology, which is applied in the field of electrical insulating thermoplastic resin composition and its preparation, can solve the problems of processing and manufacturing costs, high transportation costs, difficult recycling of metal materials, and insufficient electrical insulation performance. Long, good interfacial compatibility, excellent electrical insulation properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

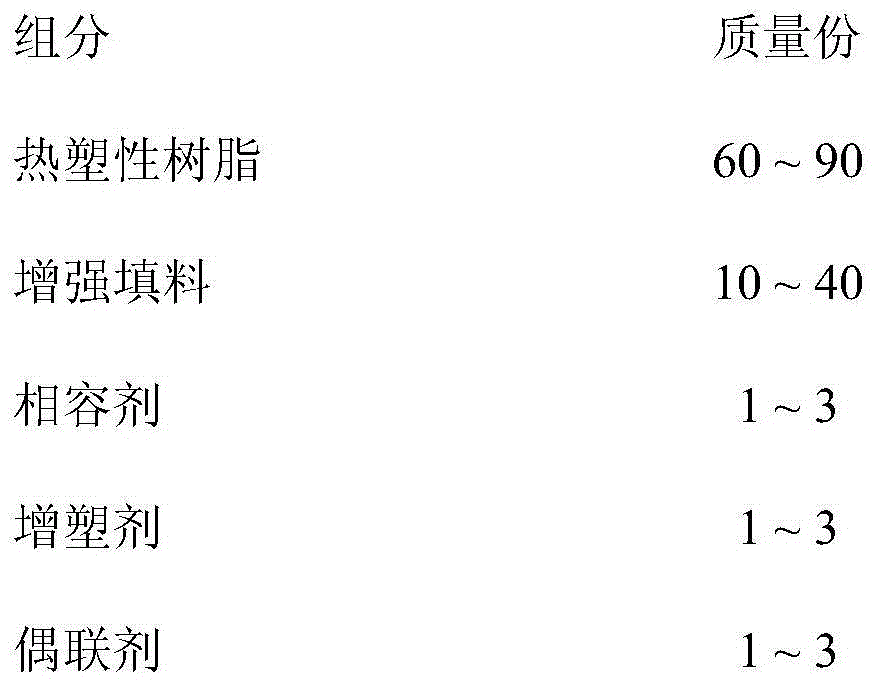

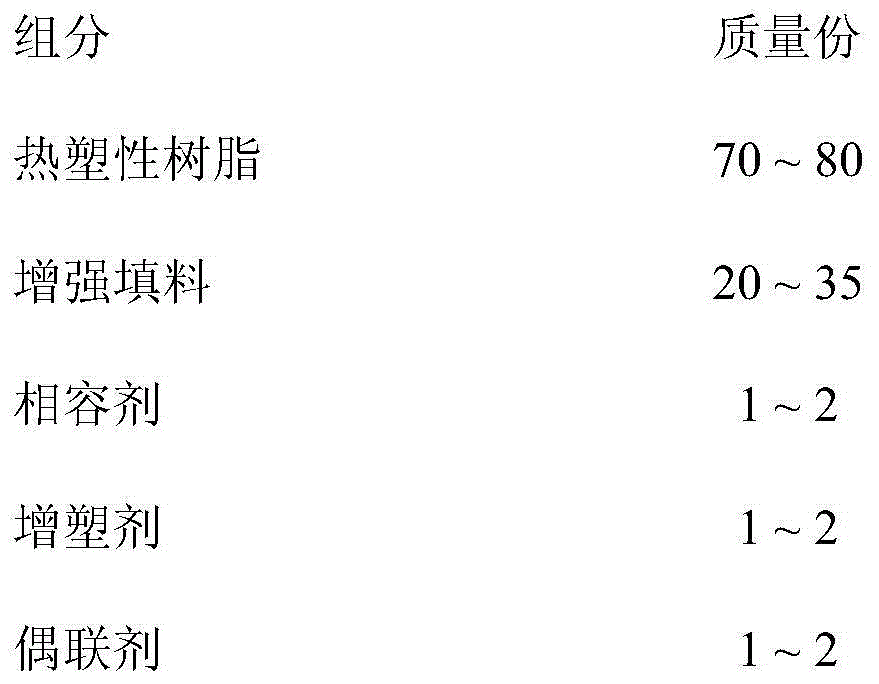

Method used

Image

Examples

Embodiment 1

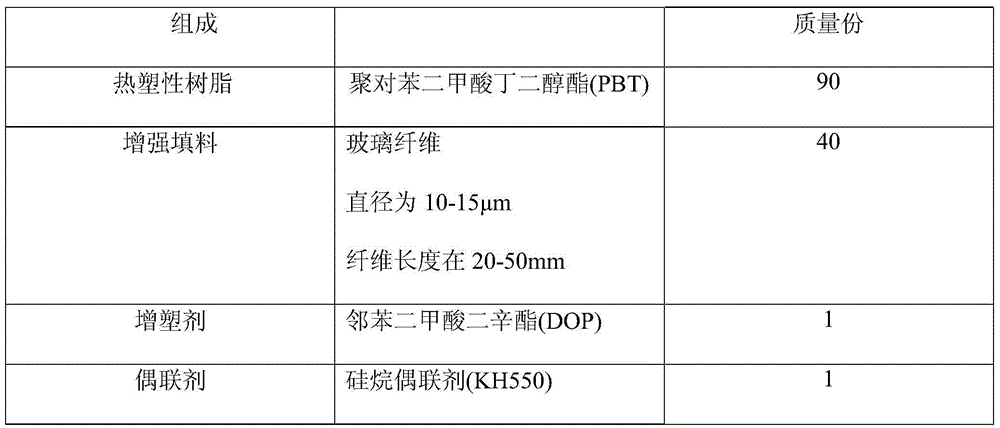

[0051] The formula of thermoplastic resin composition is as follows:

[0052]

[0053] Preparation:

[0054] (1) Dry polybutylene terephthalate (PBT) in an oven at 110°C for 4 hours;

[0055] (2) Set the four stages of processing melting temperature of the twin-screw extruder to 265°C / 280°C / 290°C / 285°C, the head temperature to 280°C, set the speed of the main engine and the speed of the cutting machine to 100rpm / min and 300rpm / min, water cooling;

[0056] (3) adding the dried thermoplastic resin and auxiliary agent into the twin-screw extruder set in step (2) to obtain thermoplastic resin composition pellets;

[0057] (4) Set the nozzle temperature of the injection molding machine to 335°C, the temperature of the three stages to 310°C / 335°C / 330°C, the mold temperature to 120°C, the cooling time to 10s, the injection pressure to 3.5Mpa, and the holding pressure to 4Mpa and the holding time is 5s;

[0058](5) Put the thermoplastic resin composition pellets obtained in ste...

Embodiment 2

[0060] The formula of thermoplastic resin composition is as follows:

[0061]

[0062]

[0063] Preparation:

[0064] (1) Dry the high-temperature nylon in an oven at 110°C for 4 hours;

[0065] (2) Set the four stages of processing and melting temperature of the twin-screw extruder to 265°C / 280°C / 290°C / 285°C, the head temperature to 280°C, set the speed of the main engine and the speed of the cutting machine to 100rpm / min and 300rpm / min, water cooling;

[0066] (3) adding the dried thermoplastic resin and auxiliary agent into the twin-screw extruder set in step (2) to obtain thermoplastic resin composition pellets;

[0067] (4) Set the nozzle temperature of the injection molding machine to 335°C, the temperature of the three stages to 310°C / 335°C / 330°C, the mold temperature to 120°C, the cooling time to 10s, the injection pressure to 3.5Mpa, and the holding pressure to 4Mpa and the holding time is 5s;

[0068] (5) Put the thermoplastic resin composition pellets obta...

Embodiment 3

[0070] The formula of thermoplastic resin composition is as follows:

[0071]

[0072] Preparation:

[0073] (1) Dry the high-temperature nylon in an oven at 110°C for 4 hours;

[0074] (2) Set the four stages of processing and melting temperature of the twin-screw extruder to 265°C / 280°C / 290°C / 285°C, the head temperature to 280°C, set the speed of the main engine and the speed of the cutting machine to 100rpm / min and 300rpm / min, water cooling;

[0075] (3) adding the dried thermoplastic resin and auxiliary agent into the twin-screw extruder set in step (2) to obtain thermoplastic resin composition pellets;

[0076] (4) Set the nozzle temperature of the injection molding machine to 335°C, the temperature of the three stages to 310°C / 335°C / 330°C, the mold temperature to 120°C, the cooling time to 10s, the injection pressure to 3.5Mpa, and the holding pressure to 4Mpa and the holding time is 5s;

[0077] (5) Put the thermoplastic resin composition pellets obtained in step...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com