Method of purifying foot-and-mouth disease inactivated virus antigen through ion exchange chromatography

An ion-exchange chromatography and virus antigen technology, applied in the field of chromatographic separation for the separation and purification of foot-and-mouth disease inactivated virus vaccine antigens, can solve the problems of poor safety, death, and easy loss of immune activity of antigens, and achieves low cost, few operation steps, and large scale. The effect of practical application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Get 100mL of cell culture supernatant containing FMD virus, the total protein concentration is 0.47g / L, and the FMD virus antigen concentration is 2.8 μg / mL.

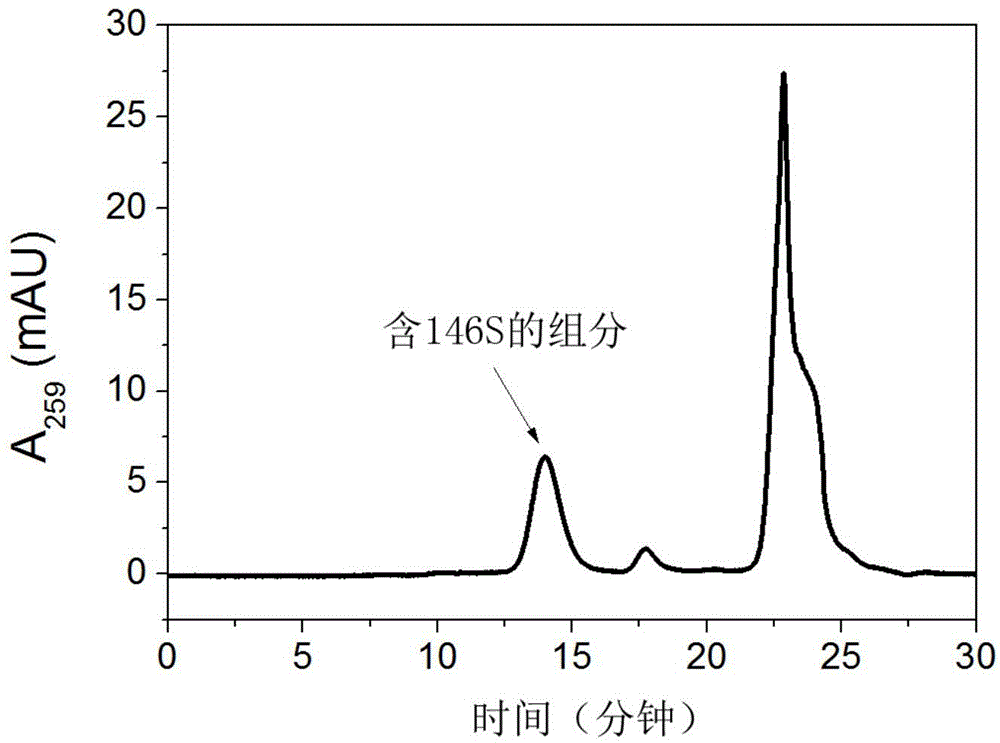

[0031] Use a plate ultrafiltration membrane (Sartorius) with a molecular weight cut-off of 50kDa to concentrate the cell supernatant to about 10mL at one time, add 80mL 20mM pH 7.0 sodium phosphate buffer solution several times to dilute, and continue to concentrate to about 10mL until the conductivity is about 7.0mS / cm; during ultrafiltration, the membrane flow rate is 10cm / s, and the pressure is controlled below 0.3Mpa. The final concentration of FMD virus antigen was about 20 μg / mL.

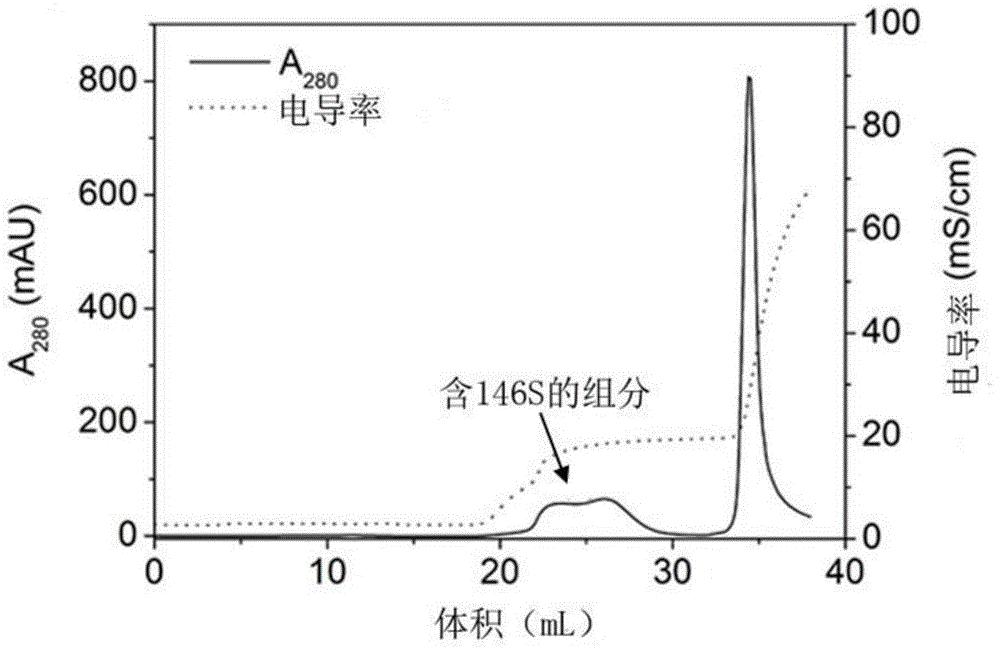

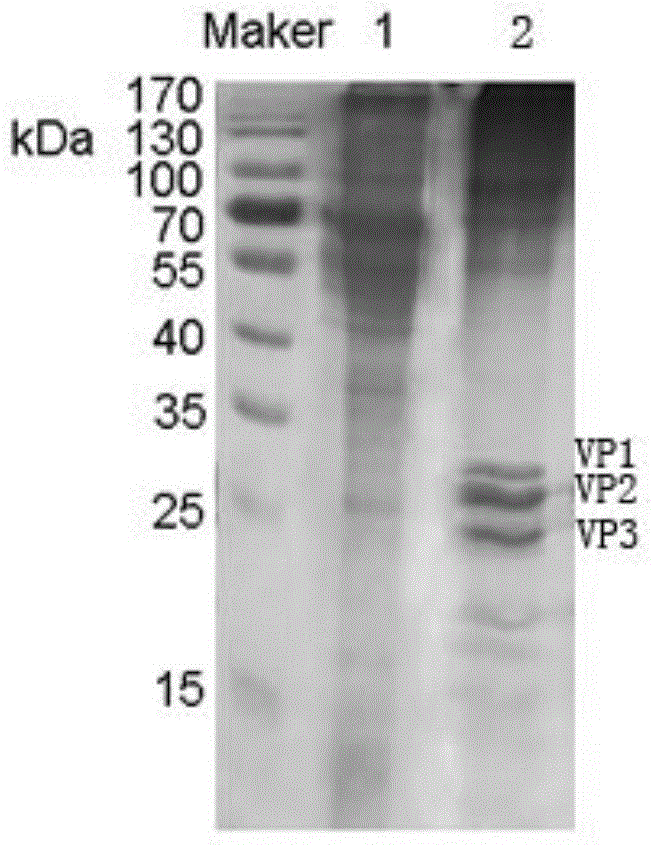

[0032] The supernatant was fed into a DEAE Sepharose FF ion-exchange chromatographic column (GE Healthcare, 5cm×1.6cm I.D.) equilibrated with sodium phosphate buffer (pH 7.0) adjusted to conductivity 7mS / cm in advance with sodium chloride, after feeding After continuing to rinse, use sodium chloride to adjust the conductance to...

Embodiment 2

[0037] Take 100mL supernatant of cell culture medium containing FMD virus, the total protein concentration is 4.5g / L, the FMD virus antigen concentration is 21μg / mL, dilute 10 times with 20mM Tris-HCl buffer solution, pH 9.0 to a conductivity of 1mS / cm , the antigen concentration is about 2 μg / mL.

[0038]Mix the supernatant with the Q Sepharose FF ion-exchange packing pre-balanced with Tris-HCl buffer (pH 9.0) adjusted to conductance 1mS / cm with ammonium chloride, stir and absorb at 100-200rpm for 30min, then add to the chromatographic column ( GE Healthcare, 5 cm x 1.6 cm I.D.). After continuous washing, ammonium chloride was used to adjust the conductivity to Tris-HCl buffer (pH 9.0) of 10-40mS / cm for gradient elution, and the ultraviolet absorption peak containing the foot-and-mouth disease virus antigen with a recovery rate greater than 20% was collected. eluent. The chromatographic packing was regenerated with 1M sodium hydroxide.

[0039] The antigen concentration an...

Embodiment 3

[0041] Get 1000mL of cell culture supernatant containing FMD virus, the total protein concentration is 0.47g / L, and the FMD virus antigen concentration is 2.8 μg / mL.

[0042] Use a plate ultrafiltration membrane (Sartorius) with a molecular weight cut-off of 300kDa to concentrate the cell supernatant to about 20mL at one time, add 100mL 20mM pH 8.0 sodium phosphate buffer solution several times to dilute, and continue to concentrate to about 10mL until the conductivity is about 5.0mS / cm; during ultrafiltration, the membrane flow rate is 100cm / s, and the pressure is controlled below 0.3Mpa. The final concentration of FMD virus antigen is about 200 μg / mL.

[0043] The supernatant was fed to an ANX Sepharose FF (high sub) ion-exchange chromatographic column (GE Healthcare, 15cm×1.6cm I.D.) equilibrated with sodium phosphate buffer (pH 8.0) adjusted to conductance 7mS / cm with ammonium sulfate in advance, After feeding, after continuing to rinse, use ammonium sulfate to adjust th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com