Crosslinked ultrahigh molecular weight polyethylene fiber and wet preparation method thereof

A technology of ultra-high molecular weight polyethylene fiber, applied in the direction of single-component polyolefin artificial filament, wet spinning method, fiber chemical characteristics, etc., can solve the problems of fracture, mechanical strength and elongation resistance of ultra-high molecular weight polyethylene fiber High temperature performance, reduced creep resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

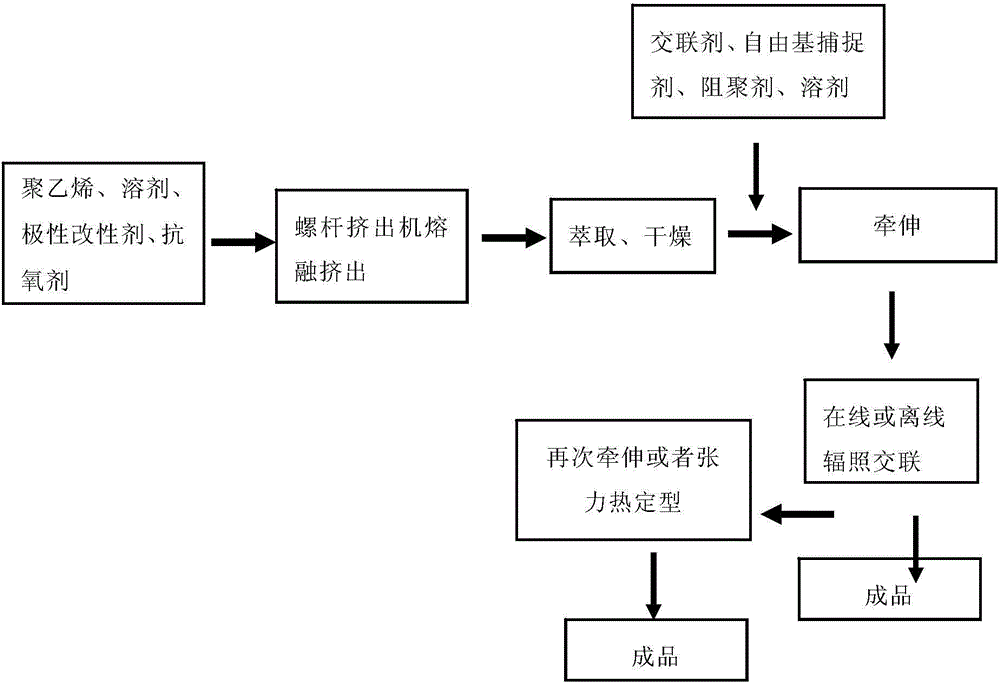

Method used

Image

Examples

Embodiment 1

[0071] Weigh 3 parts by weight of ultra-high molecular weight polyethylene powder (Gur 4022 of Ticona Company, the molecular weight range is 3 million), 0.003 parts by weight of antioxidant 2,6-di-tert-butylphenol, polar modifier 2-phenoxy 0.003 parts by weight of ethyl ethyl acrylate and 100 parts by weight of solvent white oil, the above raw materials were thoroughly mixed to prepare a spinning solution with a polyethylene concentration of 3 wt%. In spinning equipment (produced by Jiangsu Shentai Technology Development Co., Ltd., spinning temperature: screw preheating zone: 60~110°C, melting zone: 150°C, metering zone: 160°C, compression zone: 170°C, box temperature : 170 ℃), the spinning solution is extruded and spun by a screw to form jelly yarn. The jelly yarn is pre-stretched 1.2 times at room temperature, and is extracted with hydrocarbon cleaning agent 103 to form extraction yarn, and the extraction yarn is processed. Two-stage drying, respectively drying at 40°C for 1...

Embodiment 2

[0081] Take by weighing 3 parts by weight of ultra-high molecular weight polyethylene powder (the ultra-high molecular weight adopts Gur4022 of Ticona Company, the molecular weight range is 4 million), antioxidant 2,6-di-tert-butylphenol and 4,4'-thiobis( 0.003 parts by weight of 6-tert-butyl-3-methylphenol), 0.003 parts by weight of polar modifier lauric acid acrylate, and 100 parts by weight of solvent mineral oil. The above raw materials were thoroughly mixed to prepare a spinning solution with a polyethylene concentration of 4 wt%. In spinning equipment (produced by Jiangsu Shentai Technology Development Co., Ltd., spinning temperature: screw preheating zone: 60~110°C, melting zone: 150°C, metering zone: 160°C, compression zone: 170°C, box temperature: 170°C), the spinning solution was extruded through a screw to form jelly yarn, which was pre-stretched 1.2 times at room temperature, extracted with xylene to form extraction yarn, and the extraction yarn was dried in two st...

Embodiment 3

[0085] Take by weighing 3 parts by weight of ultra-high molecular weight polyethylene powder (the ultra-high molecular weight adopts Gur4022 of Ticona Company, the molecular weight range is 5 million), antioxidant 1010 is 0.01 parts by weight, antioxidant 4,4'-thiobis(6 - 0.006 parts by weight of tert-butyl-3-methylphenol), 0.003 parts by weight of cyclotrimethylolpropane acetal acrylate as a polar modifier, and 100 parts by weight of solvent mineral oil. The above raw materials were thoroughly mixed to prepare a spinning solution with a polyethylene concentration of 3 wt%. In spinning equipment (produced by Jiangsu Shentai Technology Development Co., Ltd., spinning temperature: screw preheating zone: 60~110°C, melting zone: 150°C, metering zone: 160°C, compression zone: 170°C, box temperature : 170°C), the above spinning solution is extruded through a screw to form jelly yarn, which is pre-stretched 1.2 times at room temperature, extracted with No. 120 gasoline to form extrac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average denier | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com