Vertically-oriented self-assembled segmented copolymer film, and production method and application thereof

A technology of block copolymer and vertical orientation, which is applied in the field of block copolymer thin film preparation, and can solve problems such as difficult and complex electrode structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

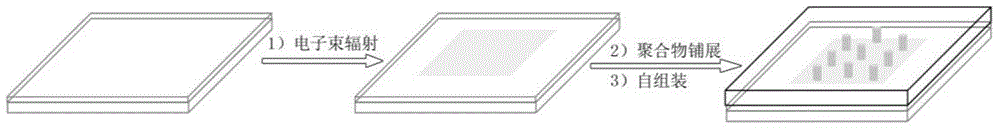

[0054] figure 1 Shown as a schematic diagram of a method for controlling the self-assembly structure of a vertically-oriented PS-b-PMMA film.

[0055] (1) Electron beam radiation

[0056] The electron beam has an acceleration voltage of 5kV, an electron beam current of 16.7pA, a radiation time of 6min (360s), and a radiation area of 11.32μm 2 (I.e. the radiation dose is 53mC / cm 2 ) Irradiate the surface of the silicon substrate containing the spontaneous oxide layer.

[0057] (2) Block copolymer spreading

[0058] The PS-b-PMMA (46k-b-21k) solution with a concentration of 9 mg / ml was spin-coated on the silicon substrate after electron beam irradiation at 2000 rpm for 40 seconds.

[0059] (3) Polymer self-assembly

[0060] The substrate containing the PS-b-PMMA film was annealed in a tube furnace at 250°C under Ar atmosphere for 2 hours, cooled to room temperature, and self-assembly was completed.

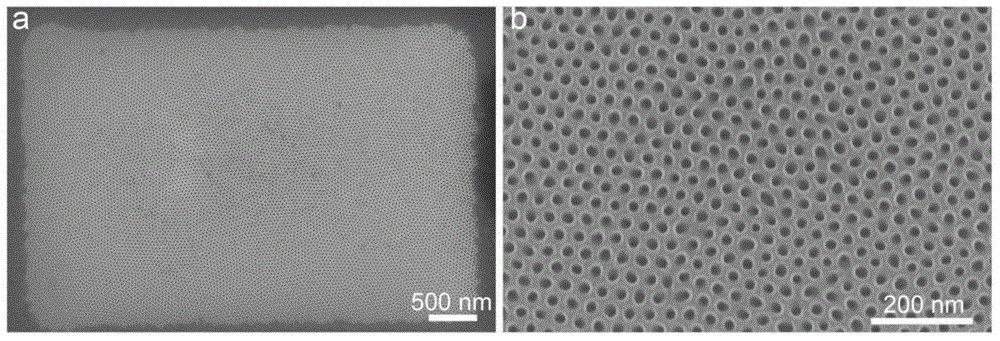

[0061] Finally, the annealed film was etched by argon plasma (20sccm, 50W, 5min), and the...

Embodiment 2

[0065] (1) Electron beam radiation

[0066] The electron beam has an acceleration voltage of 5kV, an electron beam current of 16.7pA, a radiation time of 3min, and a radiation area of 11.32μm 2 (I.e. the radiation dose is 26.5mC / cm 2 ) Irradiate the surface of a silicon substrate containing an artificial oxide layer.

[0067] (2) Block copolymer spreading

[0068] The PS-b-PMMA (53k-b-54k) solution with a concentration of 11 mg / ml was spin-coated on the silicon substrate after electron beam irradiation at 2000 rpm and 40 seconds.

[0069] (3) Polymer self-assembly

[0070] The substrate containing the PS-b-PMMA film was annealed in a tube furnace at 250°C under Ar atmosphere for 2 hours and cooled to room temperature to complete the self-assembly.

[0071] After processing according to the method of Example 1, the surface morphology was observed with a scanning electron microscope. Figure 4 It is the surface topography of the layered PS-b-PMMA film obtained in Example 2. The formed f...

Embodiment 3

[0073] (1) Electron beam radiation

[0074] The acceleration voltage of the electron beam is 5kV, the electron beam current is 16.7pA, and the radiation dose of the electron beam is 50mC / cm 2 The radiation area is a circular area with a diameter of 100 nm that radiates the surface of the silicon substrate containing the spontaneous oxide layer.

[0075] (2) Block copolymer spreading

[0076] A PS-b-PMMA (46k-b-21k) solution with a concentration of 9 mg / ml was spin-coated on the silicon substrate after electron beam irradiation at 2000 rpm for 40 seconds.

[0077] (3) Polymer self-assembly

[0078] The substrate containing the PS-b-PMMA film was annealed in a tube furnace at 250°C under Ar atmosphere for 2 hours and cooled to room temperature to complete the self-assembly.

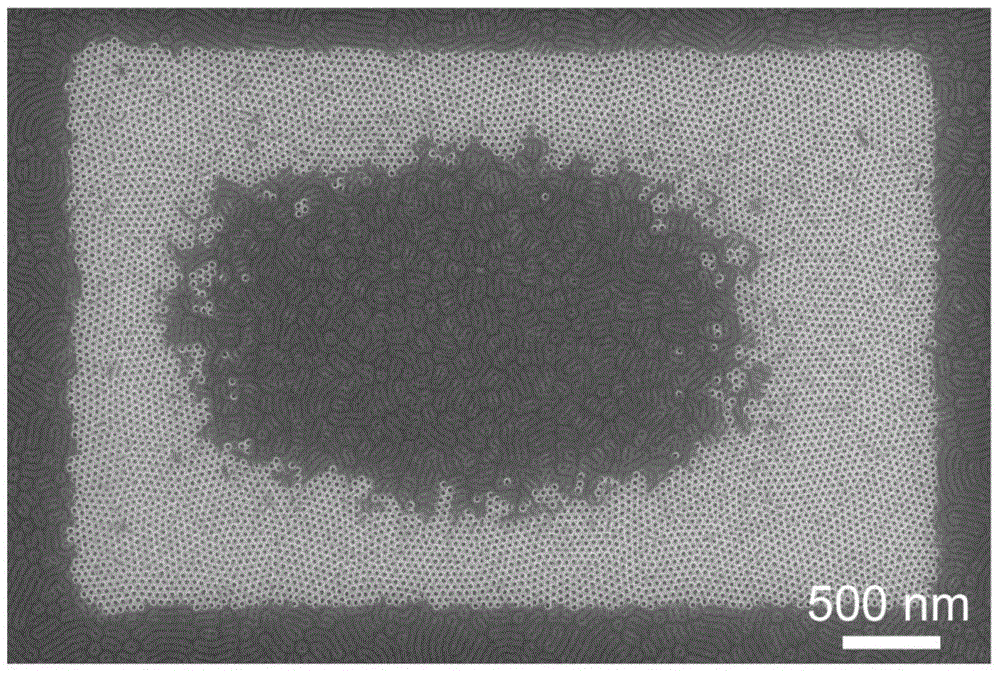

[0079] After processing according to the method of Example 1, the surface morphology was observed with a scanning electron microscope. Figure 5 It is the surface topography of the PS-b-PMMA film with the columnar str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com