Method for adopting whole-cell conversion to efficiently produce alpha-phenylpyruvic acid

A technology of phenylpyruvate and whole-cell catalyst, which is applied in the field of fermentation engineering, can solve the problems of lack of selectivity, low yield, and environmental pollution, and achieve the effect of solving cumbersome steps and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

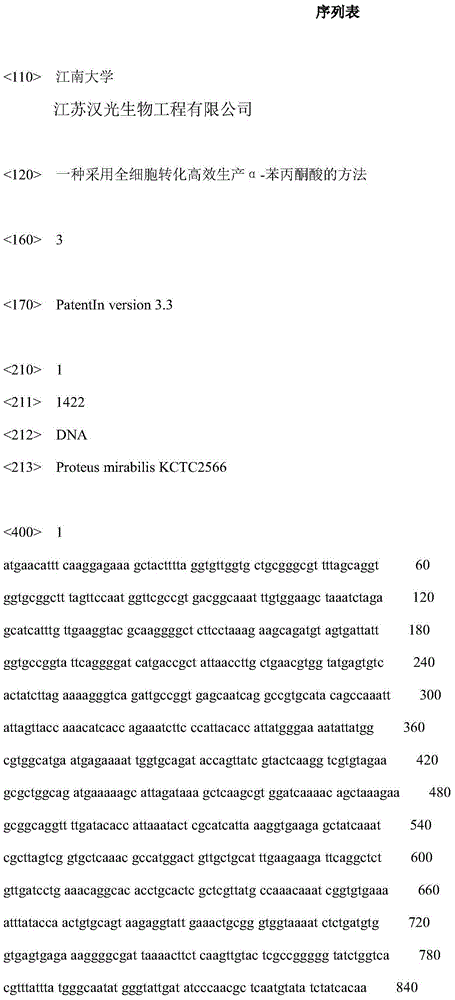

[0019] Example 1 Error-prone PCR transforms L-amino acid deaminase

[0020] Using the genome of P. mirabilisKCTC2566 as a template, the gene pma encoding L-amino acid deaminase was cloned, connected to the vector pET-20b(+), and the obtained recombinant plasmid pET-pma was used as a template, and Mutazyme II DNA polymerase low-fidelity enzyme amplification increase pma gene. After the PCR product was purified and digested, it was ligated with the vector pET-20b(+) to construct a recombinant plasmid, and transformed into Escherichia coli BL21 to construct a mutant library. Pick a single colony grown on the ampicillin-resistant plate and inoculate it into LB, culture it overnight in a 96-well plate with shaking at 37°C, inoculate it into another 96-well plate in TB medium, induce it with IPTG for 5 hours, and measure the PPA production. After the primary screening, the strains with high PPA production were re-screened by shake flask fermentation, and the substrate conversion ra...

Embodiment 2

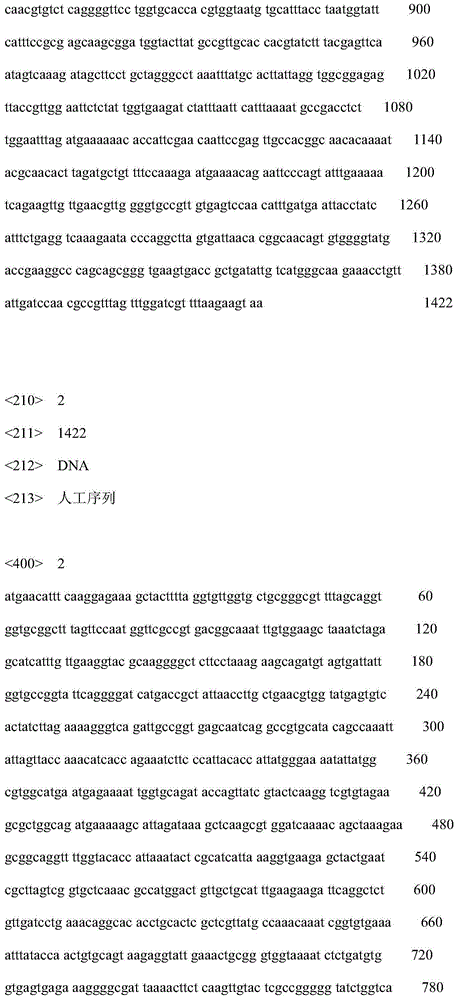

[0021] Example 2 Site-directed mutagenesis transforms L-amino acid deaminase

[0022] Site-directed saturation mutation was performed on the mutation sites of the mutants with high conversion rate obtained in Example 1 one by one. Using the mutated recombinant plasmid in Example 1 as a template, Prime-STAR HS DNA polymerase high-fidelity enzyme and designed mutation primers were amplified in one step, and the template DNA was digested with DpnI restriction endonuclease, then phosphorylated, and connected into a complete plasmid. Escherichia coli BL21 was transformed.

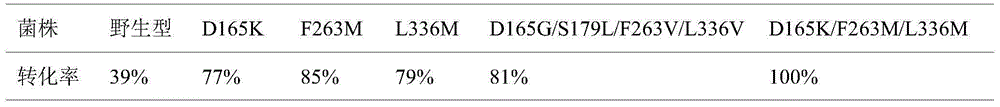

[0023] After two rounds of transformation, among the single mutants obtained, the mutants with higher PPA production were: D165K, F263M, and L336M. These several mutation sites were combined to construct the compound mutant D165K / F263M / L336M. Table 1 shows the conversion rates of whole cells transformed with recombinant bacteria containing wild-type L-amino acid deaminase and various mutants into PPA.

[0024...

Embodiment 3

[0026] Embodiment 3 preparation of whole cell catalyst and whole cell conversion process

[0027] The recombinant Escherichia coli BL21 of Example 1 and Example 2 were inoculated into seed medium (chloramphenicol 10 mg / L), and cultivated overnight at 37° C. and 200 rpm. Fermentation was carried out in a 3L NBS fermenter, 1% inoculum was added to 1.8L fermentation medium, the stirring speed, ventilation and temperature were 400rpm, 1.0vvm and 28°C, respectively, when OD 600 When 0.6 was reached, 0.4 mM IPTG was added to induce the expression of L-amino acid deaminase. After 5 hours of induction, centrifuge at 8,000 rpm for 10 minutes at low temperature, collect the bacterial cells, and wash the bacterial cells twice with 20 mM Tris-HCl (pH 8.0) buffer solution. The whole cell transformation system is: L-phenylalanine 10g / L, whole cell catalyst 1.2g / L, the reaction is carried out in 20mM Tris-HCl (pH8.0), 37°C, 200rpm transformation for 6h.

[0028] For the recombinant bacteri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com