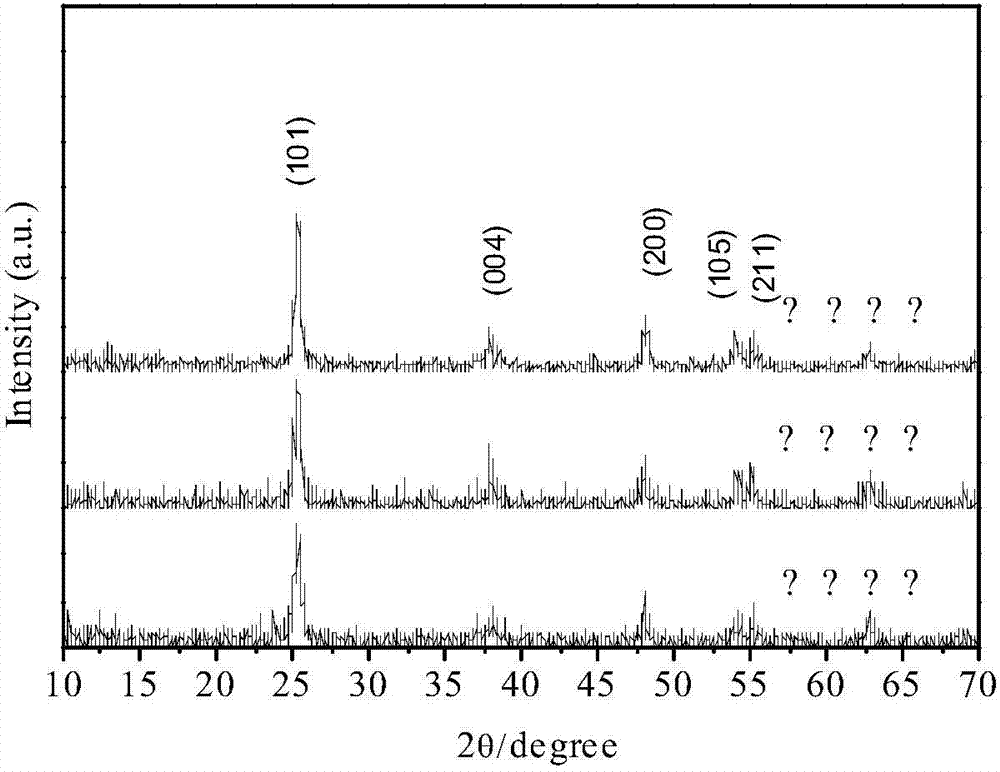

Preparation method of anatase black nano titanium oxide powder

A technology of nano-titanium oxide and anatase, applied in the direction of titanium dioxide, chemical instruments and methods, titanium oxide/hydroxide, etc., can solve problems such as difficult to meet industrialization, narrow light absorption range, complex process, etc., and meet production requirements and use requirements, easy industrialization, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

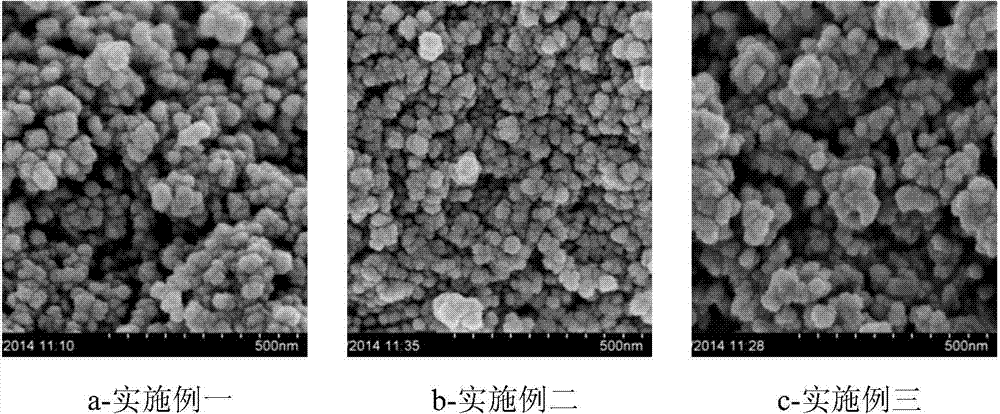

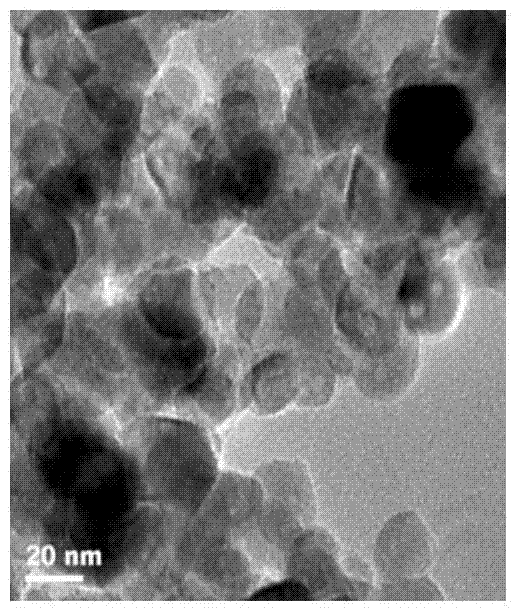

Embodiment 1

[0028] The preparation method of a kind of anatase black nano titanium oxide powder of the present embodiment, its steps are as follows:

[0029] (1) Ti 4+ Solution preparation

[0030] At room temperature, add 20g of ammonium fluorotitanate powder into 200ml of deionized water and stir until the ammonium fluorotitanate powder is completely dissolved to form a transparent Ti 4+ solution;

[0031] (2) Preparation of raw material solution

[0032] According to molar ratio Ti 3+ / Ti 4+ = 1, in the above Ti 4+ 15% TiCl was added to the solution 3 The solution was stirred and mixed for 10 minutes to obtain a raw material solution;

[0033] (3) Precipitation reaction

[0034] Add 40g of precipitant propionic acid to the above raw material solution, stir and add 0.1mol / L dilute ammonia water until the pH value of the solution system is 5, and a blue precipitate is formed;

[0035] (4) Precipitate Calcination

[0036] The above precipitate was filtered and washed repeatedly ...

Embodiment 2

[0038] The preparation method of a kind of anatase black nano titanium oxide powder of the present embodiment, its steps are as follows:

[0039] (1) Ti 4+ Solution preparation

[0040] At room temperature, add 20g of ammonium fluorotitanate powder into 200ml of deionized water and stir until the ammonium fluorotitanate powder is completely dissolved to form a transparent Ti 4+ solution;

[0041] (2) Preparation of raw material solution

[0042] According to molar ratio Ti 3+ / Ti 4+ = 2, in the above Ti 4+ 15% TiCl was added to the solution 3 The solution was stirred and mixed for 10 minutes to obtain a raw material solution;

[0043] (3) Precipitation reaction

[0044] Add 60g of precipitant propionic acid to the above raw material solution, stir and add 0.1mol / L dilute ammonia water until the pH value of the solution system is 5, and a blue precipitate is formed;

[0045] (4) Precipitate Calcination

[0046] The above precipitate was filtered and washed repeatedly ...

Embodiment 3

[0048] The preparation method of a kind of anatase black nano titanium oxide powder of the present embodiment, its steps are as follows:

[0049] (1) Ti 4+ Solution preparation

[0050] At room temperature, add 20g of ammonium fluorotitanate powder into 200ml of deionized water and stir until the ammonium fluorotitanate powder is completely dissolved to form a transparent Ti 4+ solution;

[0051] (2) Preparation of raw material solution

[0052] According to molar ratio Ti 3+ / Ti 4+ = 3, in the above Ti 4+ 15% TiCl was added to the solution 3 The solution was stirred and mixed for 10 minutes to obtain a raw material solution;

[0053] (3) Precipitation reaction

[0054] Add 90g of precipitant propionic acid to the above raw material solution, stir and add 0.1mol / L dilute ammonia water until the pH value of the solution system is 5, and a blue precipitate is formed;

[0055] (4) Precipitate Calcination

[0056] The above precipitate was filtered and washed repeatedly wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com