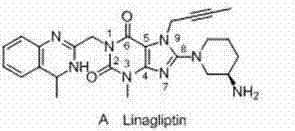

Preparation method of Linagliptin

A technology for compounds and inorganic salts, applied in the field of API preparation, can solve problems such as increased cost, process complexity, purification difficulties, etc., and achieve the effects of improving product purity, reducing purification pressure, and improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Example 1: Add 54g (0.182mol) of compound B, 40g (0.2mol) of compound F, 50g (0.364mol) of potassium carbonate, and 0.6g (0.04mol) of potassium iodide into a 2L reaction flask, and then add 270ml of NMP. Stir and heat up to 40-50°C, and stir for 2-3h. After the reaction was detected by TLC, 36.5 g (0.192 mol) of compound E was added, and the reaction was continued for 3-4 h. After the reaction was detected by TLC (DCM:MeOH=20:1), the heating was stopped and the temperature was lowered to room temperature.

[0032] Post-treatment: Add 540ml of dichloromethane and 1080ml of water, stir until the solid dissolves. Separate the liquid, extract the aqueous layer with 270ml*2DCM, combine the organic phases; add 500ml of 1% acetic acid aqueous solution to wash once, and wash once with saturated sodium chloride to obtain the organic phase. Evaporate the organic phase to dry the light yellow solid, then add 300ml of ethanol, heat to reflux to dissolve, slowly add 300ml of w...

Embodiment 2

[0033] Example 2: Add 54g (0.182mol) of compound B, 36.5g (0.192mol) of compound E, 50g (0.364mol) of potassium carbonate, and 0.6g (0.04mol) of potassium iodide into a 2L reaction flask, and then add 270ml of NMP. Stir and heat up to 40-50°C, and stir for 2-3h. After the reaction was detected by TLC, 40 g (0.2 mol) of compound F was added, and the reaction was continued for 3-4 h. After the reaction was detected by TLC (DCM:MeOH=20:1), the heating was stopped and the temperature was lowered to room temperature.

[0034] Post-treatment: Add 540ml of dichloromethane and 1080ml of water, stir until the solid dissolves. Separate the liquid, extract the aqueous layer with 270ml*2DCM, combine the organic phases; add 500ml of 1% acetic acid aqueous solution to wash once, and wash once with saturated sodium chloride to obtain the organic phase. Evaporate the organic phase to dry the light yellow solid, then add 300ml of ethanol, heat to reflux to dissolve, slowly add 300ml of w...

Embodiment 3

[0035] Example 3: Add 54g (0.182mol) of compound B, 40g (0.2mol) of compound F, 38.5g (0.364mol) of sodium carbonate, and 0.6g (0.04mol) of potassium iodide into a 2L reaction flask, and then add 270ml of NMP. Stir and heat up to 40-50°C, and stir for 2-3h. After the reaction was detected by TLC, 6.5 g (0.192 mol) of compound E was added, and the reaction was continued for 3-4 h. After the reaction was detected by TLC (DCM:MeOH=20:1), the heating was stopped and the temperature was lowered to room temperature.

[0036] Post-treatment: Add 540ml of dichloromethane and 1080ml of water, stir until the solid dissolves. Separate the liquid, extract the aqueous layer with 270ml*2DCM, combine the organic phases; add 500ml of 1% acetic acid aqueous solution to wash once, and wash once with saturated sodium chloride to obtain the organic phase. Evaporate the organic phase to dry the light yellow solid, then add 300ml of ethanol, heat to reflux to dissolve, slowly add 300ml of wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com