Fluorinated hydrogen abstraction polymer photoinitiator, preparation method and application thereof

A photoinitiator and polymer technology, applied in the field of fluorinated hydrogen abstraction polymer photoinitiator, can solve the problems of easy migration, poor stability, yellowing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

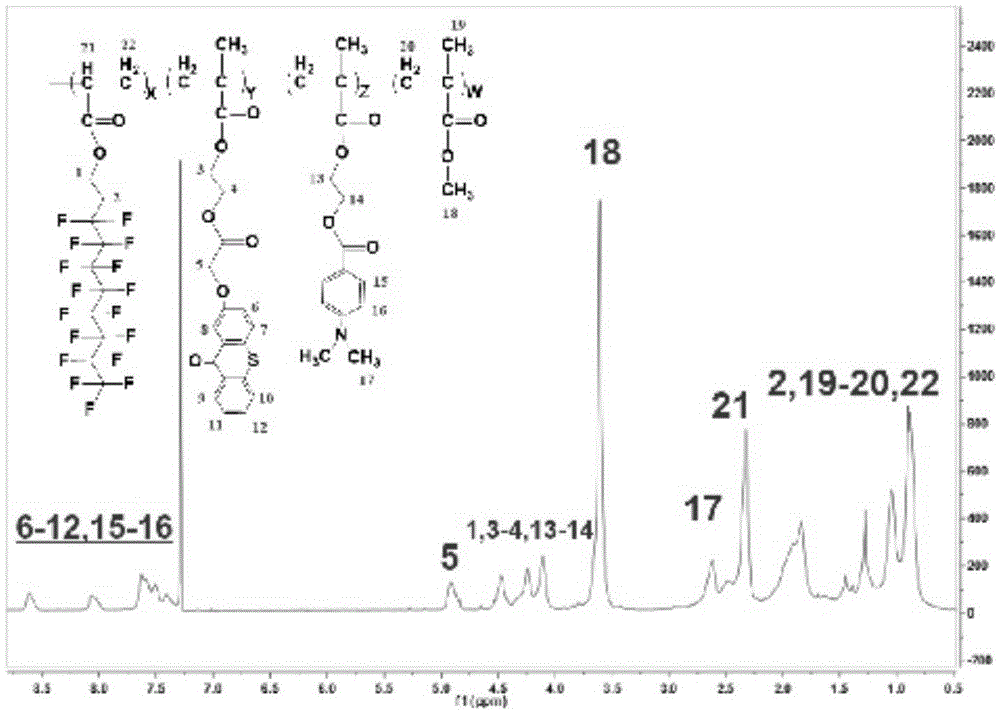

[0039] A fluorinated hydrogen abstraction polymer photoinitiator P (F-TX-A-MMA), the structural formula is as follows:

[0040]

[0041] The preparation method is as follows:

[0042] (1) 1 mole of O-(thioxanthone-[2]-yl)-oxyacetic acid and 1.2 moles of 2-hydroxyethyl methacrylate are dissolved in dichloromethane, ice-water bath, and then add 0.1 mole 4-dimethylaminopyridine and 1 mole of 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride were used as catalyst and dehydrating agent respectively, stirred, and reacted for 24 hours at normal temperature, and used Precipitate with a large amount of deionized water, filter with suction, and dry in a constant temperature vacuum oven at 70°C to prepare acrylate containing photoinitiator thioxanthone;

[0043] (2) 1 mole of p-dimethylaminobenzoic acid and 1.2 moles of 2-hydroxyethyl methacrylate are dissolved in dichloromethane, then add 0.1 mole of 4-dimethylaminopyridine and 1 mole of 1-( 3-Dimethylaminopropyl)-3-ethyl...

Embodiment 2

[0048] A fluorinated hydrogen abstraction polymer photoinitiator P(F-BP-DEMA-S), the structural formula is as follows:

[0049]

[0050] The preparation method is as follows:

[0051] (1) 1.2 moles of 4-chloromethylstyrene and 1 mole of hydroxybenzophenone are dissolved in acetonitrile, 1 mole of anhydrous potassium carbonate and catalyst amount of potassium iodide are added, refluxed for 24 hours, deionized water precipitation, Filter with suction and dry in a constant temperature vacuum oven at 60°C to obtain 3-styrene methyl ether-benzophenone.

[0052] (2) 3-Styrene methyl ether-benzophenone, perfluorooctyl ethyl acrylate, N,N-dimethylaminoethyl methacrylate and styrene in azo The copolymerization reaction of diisobutyl nitrile occurs under thermal initiation at 60°C, reacts for 24 hours, precipitates in ether, and dries in a constant temperature vacuum oven at 40°C to obtain the target product.

[0053] Figure 4 It is the structural diagram of P(F-BP-DEMA-S) synthe...

Embodiment 3

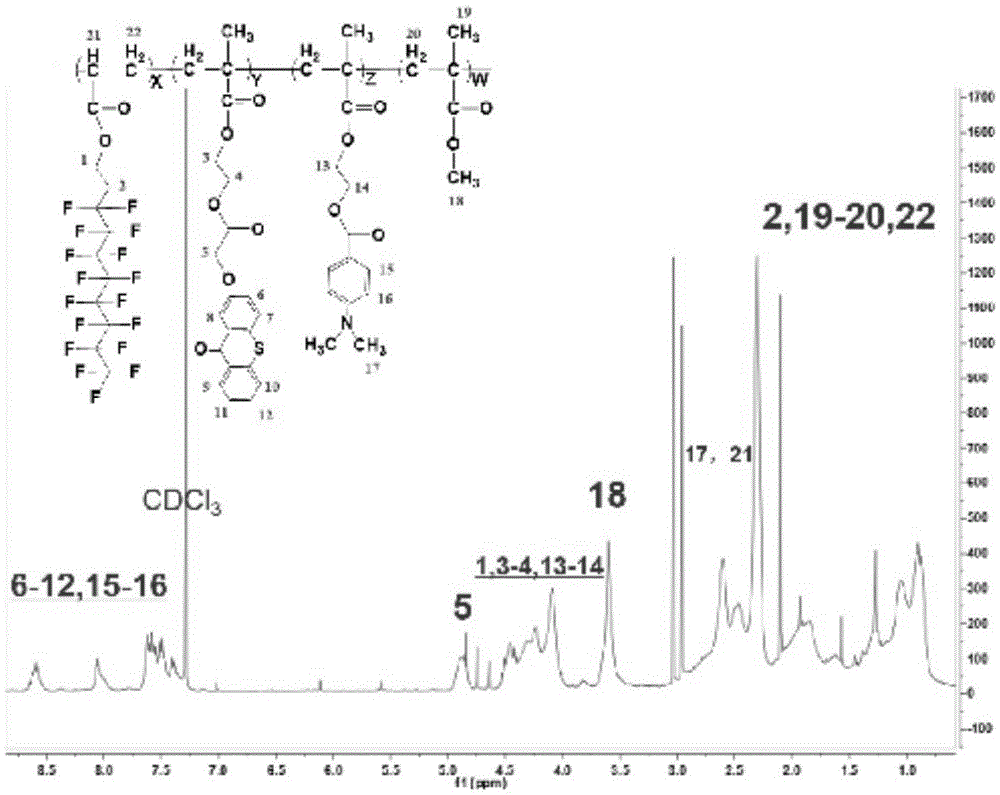

[0055] A fluorinated hydrogen abstraction polymer photoinitiator P (F-TX-DEMA-MMA), the structural formula is as follows:

[0056]

[0057] The preparation method is as follows:

[0058] (1) 1 mole of O-(thioxanthone-[2]-yl)-oxyacetic acid and 1.2 moles of 2-hydroxyethyl methacrylate are dissolved in dichloromethane, ice-water bath, and then add 0.1 mole 4-dimethylaminopyridine and 1 mole of 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride as catalyst and dehydrating agent, stirred, and reacted for 24 hours at normal temperature, using a large amount of Precipitate with deionized water, filter with suction, and dry in a constant temperature vacuum oven at 70°C to prepare acrylate containing photoinitiator thioxanthone;

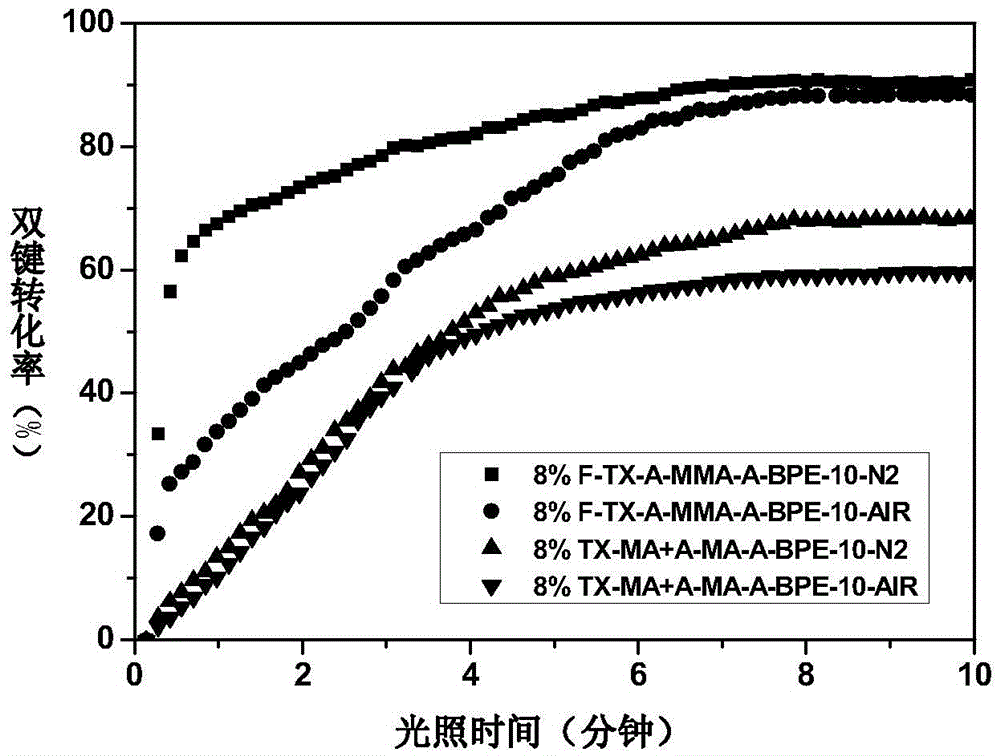

[0059] (2) According to a certain feeding ratio (X:Y:Z:W=2:30:10:10), the photoinitiator-containing thioxanthone acrylate, the co-initiator-containing amine acrylate (methacrylic acid- N,N-Dimethylaminoethyl ester), methyl methacrylate and perf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com