Soluble elemental sulfur and alicyclic olefin copolymer and preparation method thereof

A technology of alicyclic olefin and elemental sulfur, applied in the field of elemental sulfur/alicyclic olefin copolymer and its preparation, can solve the problems of poor stabilization effect of stabilizer, inability to process and use materials, small amount of stabilizer added, etc. The effect of low toxicity, low reaction temperature and high product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

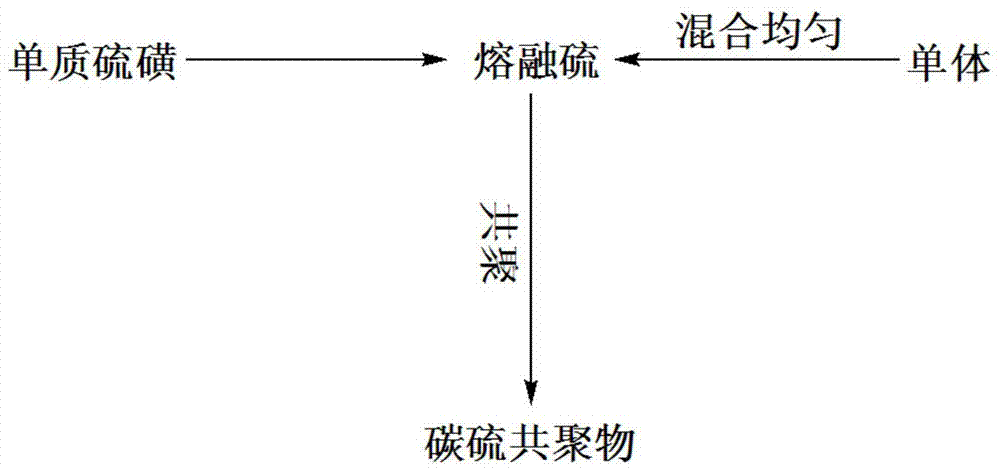

Method used

Image

Examples

Embodiment 1

[0049] Embodiment 1 contains the polysulfur copolymer of 10wt% limonene

[0050] (1) First add 9g of sublimed sulfur into a 50mL three-necked flask without catalyst, 2Heat to 120°C under atmosphere, after the sulfur is completely melted, add 1g limonene, and stir at 600r / min for 5min until uniform;

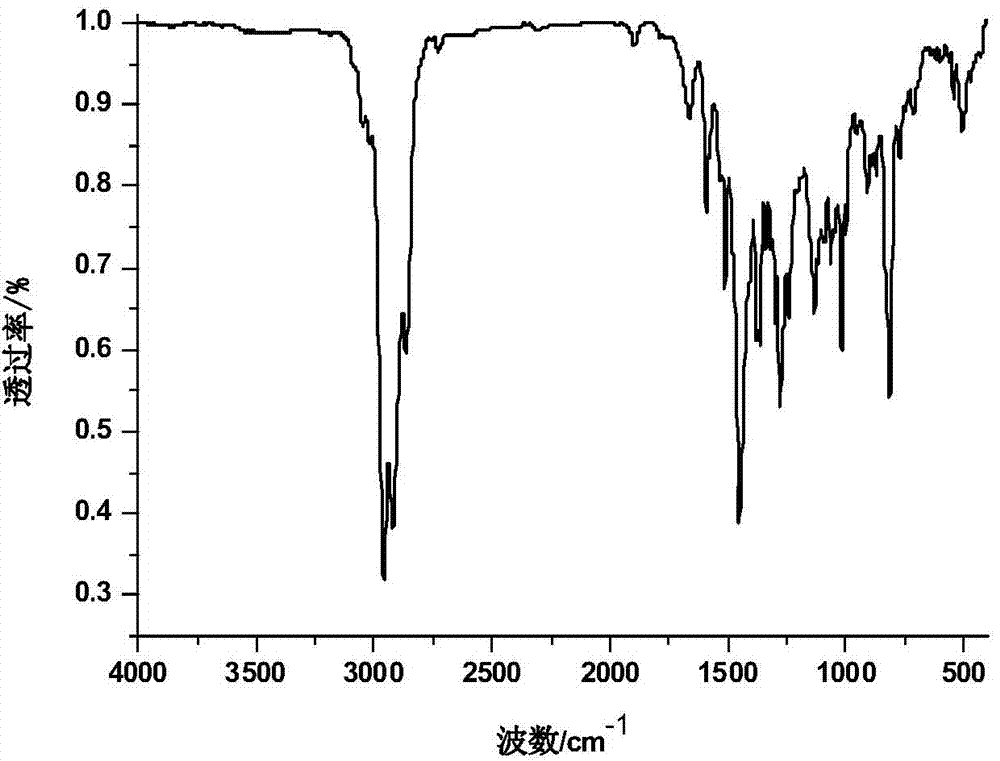

[0051] (2) Warm up the uniformly mixed reaction system in step (1) to 250°C to carry out polymerization reaction. After 0.5h of polymerization reaction, pour the product into liquid nitrogen and quickly cool it to room temperature to solidify, that is, the polymerization The crude product of the sulfur copolymer; then the purification of the crude product of the polymerized sulfur copolymer is carried out by precipitation method: the crude product of the obtained polymerized sulfur copolymer is dissolved in tetrahydrofuran to saturation, filtered, and the filtrate is added to anhydrous Precipitate in ethanol for 15 minutes, then filter the obtained suspension under reduced pressu...

Embodiment 2

[0052] Example 2 Polymerized sulfur copolymer containing 30 wt% limonene

[0053] (1) First add 7g of sublimed sulfur in a 50mL three-necked flask, add 0.5wt% (0.5% of the mass of elemental sulfur) of hexamethylenetetramine, and 2 Heating to 158°C under atmosphere, after the sulfur is completely melted, add 3g of limonene, and stir at a speed of 450r / min for 5min until uniform;

[0054] (2) Warm up the uniformly mixed reaction system in step (1) to 180°C to carry out polymerization reaction. After 1 hour of polymerization reaction, pour it into liquid nitrogen and quickly cool it to room temperature to solidify, that is, the polymerized sulfur copolymer in the form of an orange-red blocky solid is obtained. Then use the precipitation method to carry out the purification of the crude product of the polymerized sulfur copolymer: dissolve the crude product of the obtained polymerized sulfur copolymer in dichloromethane to saturation, filter, and add the filtrate to isopropyl alco...

Embodiment 3

[0055] Example 3 Polymerized sulfur copolymer containing 50 wt% limonene

[0056] (1) First add 5g of sublimed sulfur in a 50mL there-necked flask, add 1wt% (1% of the mass of elemental sulfur) of ammonium persulfate, and 2 Heat to 158°C under atmosphere, after the sulfur is completely melted, add 5g limonene, and stir at a speed of 300r / min for 10min until uniform;

[0057] (2) Heat the uniformly mixed reaction system in step (1) to the boiling point of limonene, that is, 177°C, and carry out polymerization reaction. After 6 hours of polymerization reaction, pour it into liquid nitrogen and quickly cool it to room temperature to solidify, and a red blocky solid is obtained. The crude product of polymerized sulfur copolymer. Then adopt the precipitation method to carry out the purification of the crude product of the polymerized sulfur copolymer: dissolve the crude product of the obtained polymerized sulfur copolymer in pyridine to saturation, filter, add the filtrate to meth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com