Inorganic hydrophobic insulation board and its production equipment and process

A production process and technology of thermal insulation boards, which are applied in the field of building materials, can solve the problems of poor performance of thermal insulation board materials, and achieve the effects of good expansion performance, uniform mixing and good heat resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

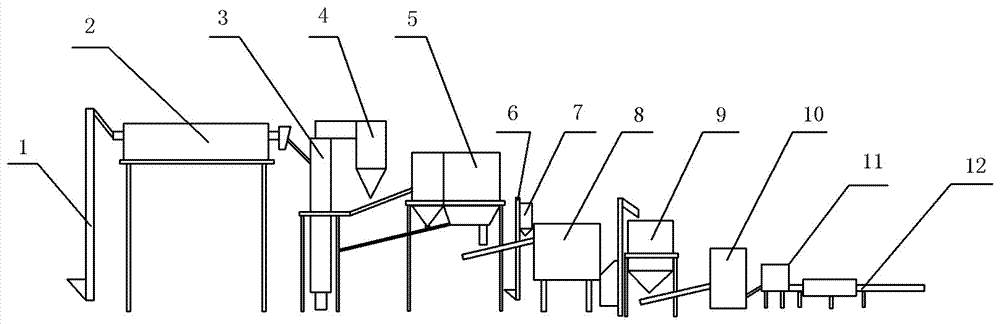

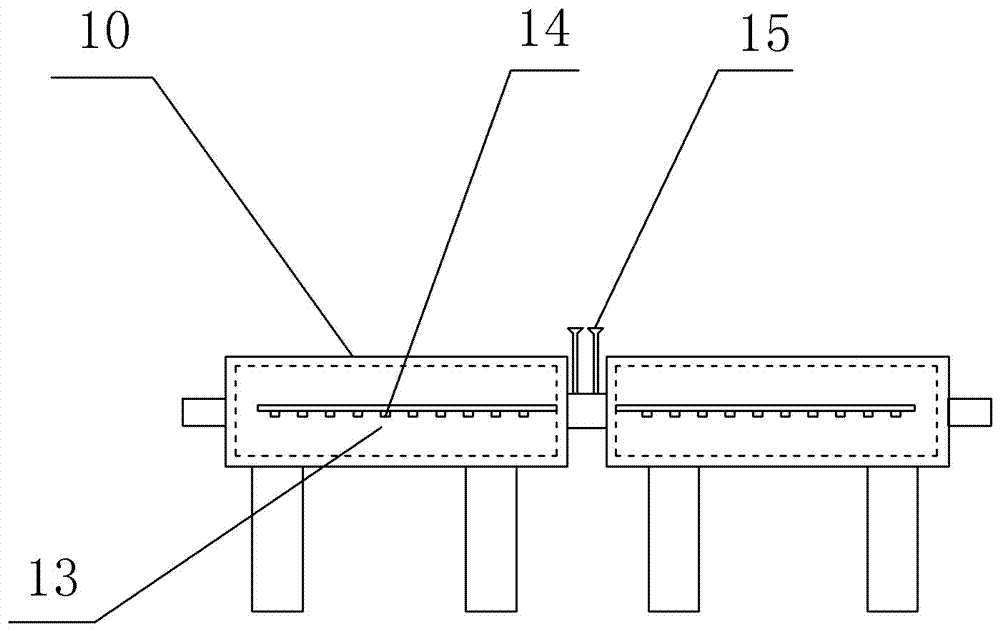

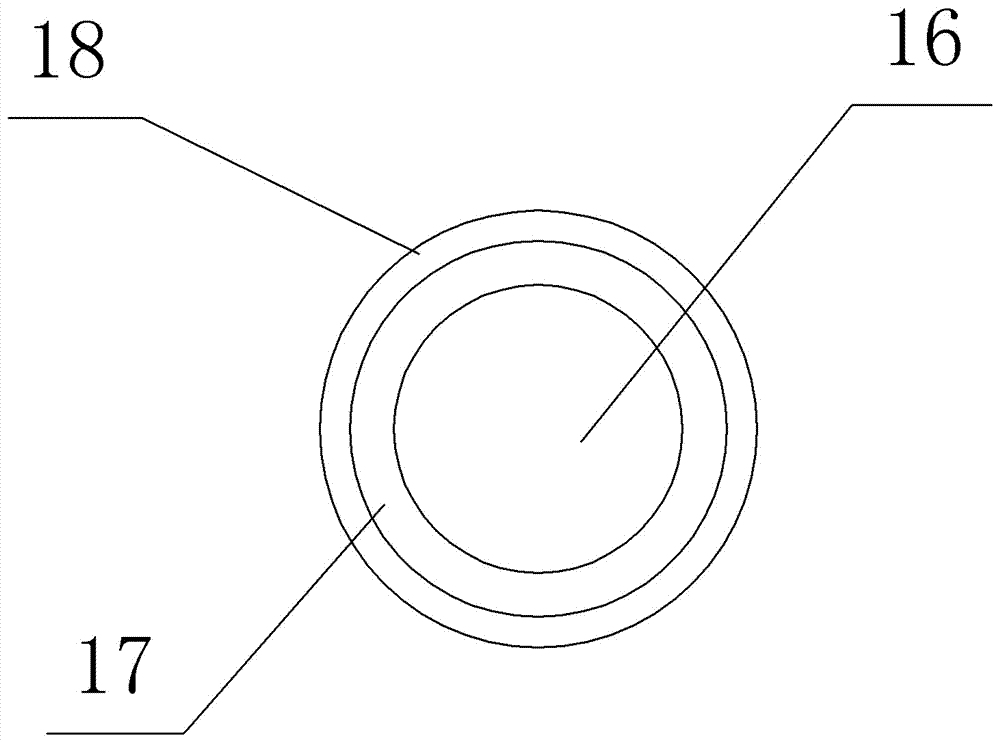

[0041] The reference signs in the drawings of the description include: the first hoist 1, the preheating furnace 2, the expansion furnace 3, the cyclone separator 4, the raw material storage bin 5, the auxiliary material bin 6, the modification reactor 7, and the second hoist 8 , silo 9, drum mixer 10, plate press 11, drying line 12, mixing bin 13, nozzle 14, feeding port 15, modified expanded perlite 16, sodium silicate layer 17, cement layer 18.

[0042] Such as figure 1 As shown, a kind of inorganic hydrophobic insulation board manufacturing equipment in this embodiment includes the first hoist 1, preheating furnace 2, expansion furnace 3, cyclone separator 4, raw material storage bin 5, auxiliary material bin connected in sequence 6. Modification reactor 7, second elevator 8, silo 9, drum mixer 10, platen press 11 and drying line 12. The raw material is expanded perlite, the auxiliary material is silicone rubber, and the materials are sodium silicate solution (water glass...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com