Method for coating graphite anode material of lithium ion battery with graphene and application thereof

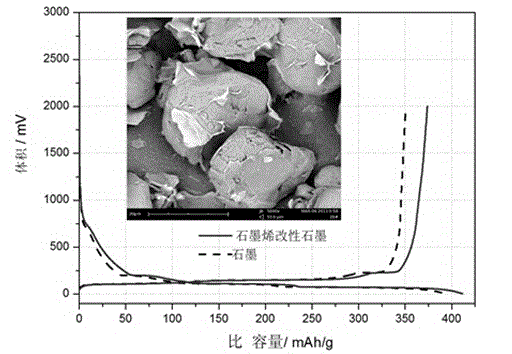

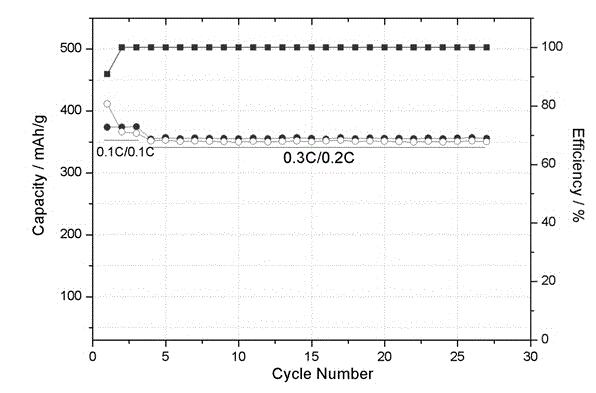

A lithium-ion battery and graphene-coated technology, which is applied to battery electrodes, secondary batteries, circuits, etc., can solve problems such as agglomeration problems, reduced cycle life of negative electrode materials, cracking and pulverization of graphite particles, etc. , to achieve the effect of excellent cycle performance, good coating effect and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] 1. Weigh 10g of graphite sample (natural spherical graphite) into a 250ml beaker, add a small amount of ethanol, stir and disperse with ultrasound, then add water, ultrasound, and make 100ml of graphite suspension;

[0028] 2. Weigh 0.2g of graphite oxide into a 100ml beaker, add water, and make 50ml of graphene oxide aqueous solution under ultrasonic stirring;

[0029] 3. Under stirring, slowly add 50ml of graphene oxide aqueous solution to 100ml of graphite suspension, then ultrasonic for 30 minutes, and continue to stir for 2 hours to obtain a mixed solution;

[0030] 4. Suction filter the above mixture, and dry the obtained solid powder in a fume hood overnight, and then dry it in a vacuum oven at 50°C for 10 hours;

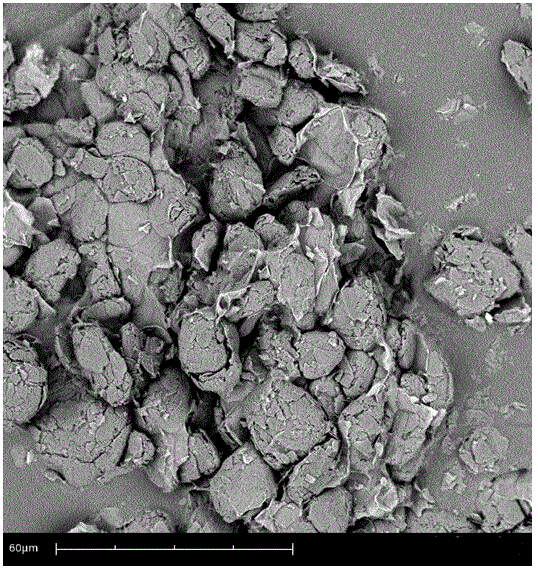

[0031] 5. Put the dried solid powder sample into the tube furnace, pass through N 2 (Flow rate 50ml / min), then raised to 800°C at 2°C / min, sintered at this temperature for 2 hours and then cooled to room temperature to obtain a graphene-coated graphit...

Embodiment 2

[0036] Change the sintering temperature to 900°C, and other conditions are as in Example 1.

Embodiment 3

[0038] Change the sintering time to 4 hours, and other conditions are as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com