A controllable livestock and poultry insulation bed device

A livestock and poultry hotbed technology, applied in poultry farming, animal husbandry, poultry cages or houses, etc., can solve the problems of non-adjustable temperature control, high energy consumption of heating devices, and low comfort, so as to prevent heat from being transmitted downwards , reduce heat preservation energy consumption, improve the effect of comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

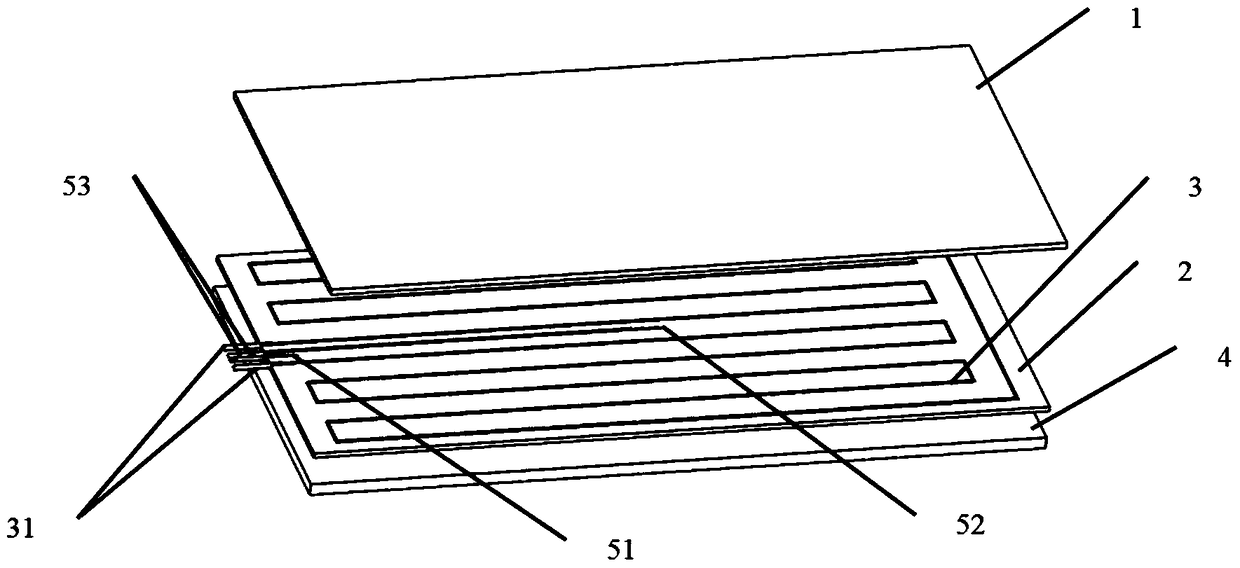

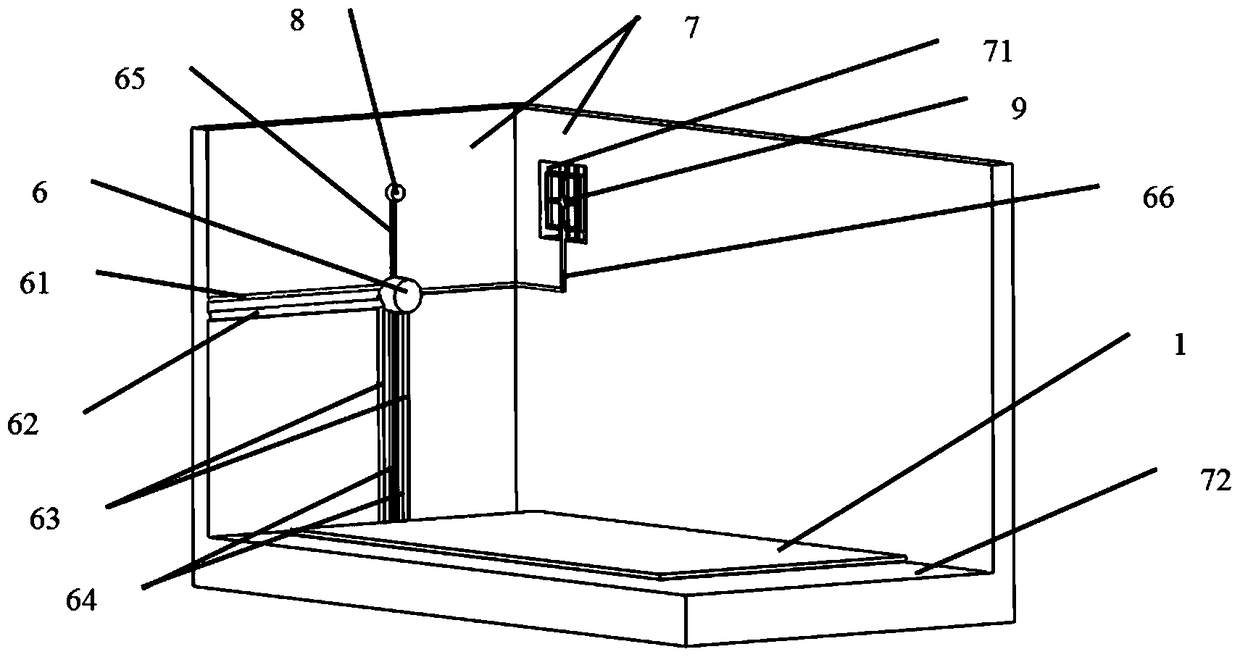

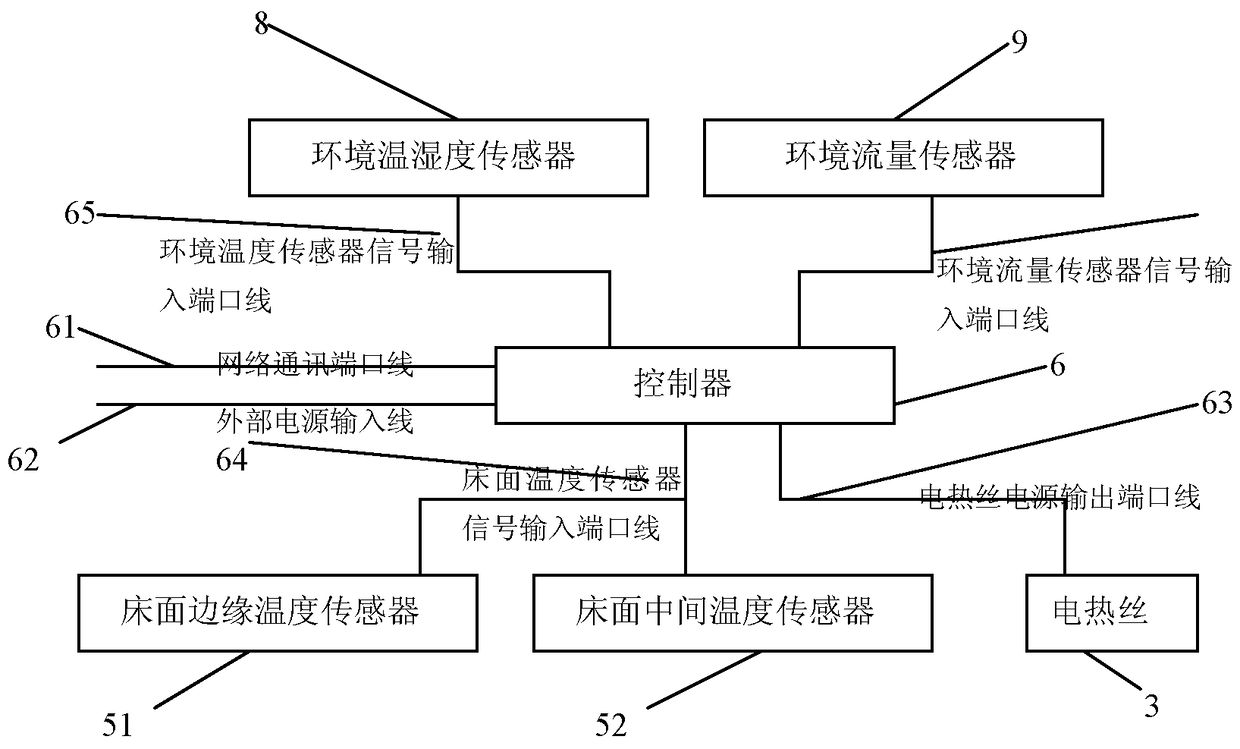

[0025] refer to figure 1 , figure 2 and image 3 , this embodiment includes a hotbed structure and a temperature control and heat preservation structure. The hotbed structure includes a bed surface layer 1, a heat conduction layer 2, a heating wire 3, and a heat insulation layer 4. The control structure includes a bed surface edge temperature sensor 51 , an ambient temperature and humidity sensor 8, an ambient flow sensor 9 and a controller 6; the hotbed structure is composed of a bed surface layer, a heat-conducting layer, and a heat-insulating layer; the heating wire 3 is evenly embedded in the heat-conducting layer 2, the power input port line 31 of the heating wire 3 is connected to the power control output port of the controller 6; the bed surface layer 1, the heat conduction layer 2, the heating wire 3 and the thermal insulation layer 4 constitute a hotbed structure, and the hotbed structure is laid on the floor of the room 72; the bed surface edge temperature sensor ...

Embodiment 1

[0026] In this embodiment 1:

[0027] The bed surface layer 1 is a BNC synthetic plastic board. The heat conduction layer 2 is a combination of heat conduction concrete and aluminum plate. The heating wire 3 is a carbon fiber heating wire. The thermal insulation layer 4 is a high-density thermal insulation foam board. The bed surface temperature sensor 51 is a resistance temperature sensor. Intelligent controller 6 is made up of single-chip microcomputer and its peripheral electronic devices. The ambient temperature and humidity sensor 8 is a combination of a temperature sensor and a humidity sensor. The ambient flow sensor 9 is a turbine flow sensor.

[0028] The working principle of the present embodiment 1 is as follows:

[0029] The controller 6 receives and saves the set temperature value through the network communication port 61; the controller 6 collects the signal of the edge temperature sensor 51 of the bed surface in real time, and calculates and analyzes the t...

specific Embodiment 2

[0031] The characteristics of this embodiment are: except that there is no environment temperature and humidity sensor 8 and environment flow sensor 9, others are the same as Embodiment 1.

[0032]This embodiment 2 except that the bed temperature cannot be adjusted with environmental changes, its working principle is the same as that of embodiment 1. When the influence of humidity and flow on the breeding conditions is relatively low, the above components can be omitted to save economic costs.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com