Catalyst for preparing succinic anhydride by hydrogenation of maleic anhydride and preparation method thereof

A succinic anhydride and catalyst technology, which is applied to the supported iron catalyst for catalyzing the hydrogenation of maleic anhydride to produce succinic anhydride and the field of preparation thereof, can solve the problems of high content of nickel as an active component, influence industrialization promotion, harsh process conditions, etc. The effect of low content, easy control of reduction operation and concise preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

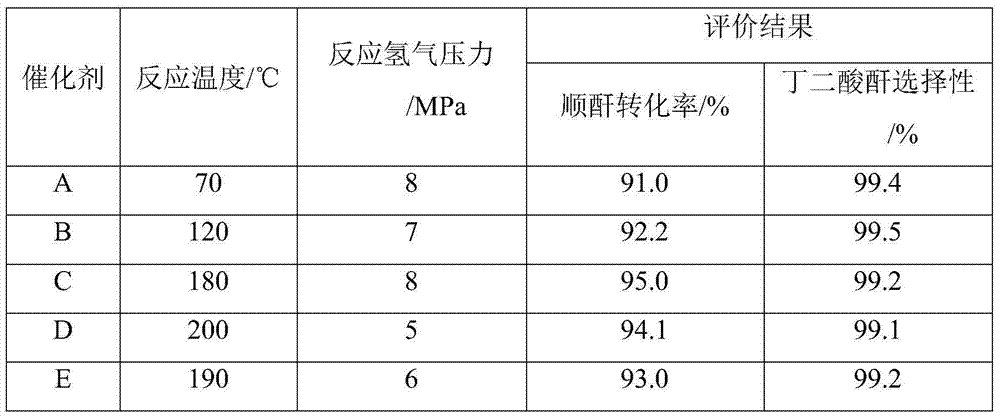

Examples

Embodiment 1

[0027] The PHTS carrier was roasted in a muffle furnace at 400°C for 5h, and then cooled to room temperature for later use. Weigh a certain amount of ferric sulfate and dissolve in 2×10 -2 mol / L 2.5 generation PAMAM solution, made into iron salt solution, the iron concentration in the solution is 5×10 -2 mol / L; Measure 200ml of the above iron salt solution and immerse it in 20g of the above treated carrier, stir for 50min, then add 300ml of 0.1mol / l sodium borohydride solution dropwise, continue to stir for 60min, centrifuge, and dry at 50℃. Get catalyst A.

Embodiment 2

[0029] The Al-PHTS carrier was roasted in a muffle furnace at 500°C for 5h, and then cooled to room temperature for later use. Weigh a certain amount of ferrous sulfate and dissolve in 2×10 -2 mol / L 2.0 generation PAMAM solution, made into iron salt solution, the iron concentration in the solution is 5.5×10 -2 mol / L; Measure 200ml of the above solution and immerse it in 40g of the above-mentioned treated carrier, stir for 80min, then add 320ml of 0.1mol / l potassium borohydride solution dropwise, continue to stir for 100min, centrifuge, and dry at 70℃ to obtain the catalyst B.

Embodiment 3

[0031] The Al-PHTS carrier was calcined in a muffle furnace at 450°C for 5h, and then cooled to room temperature for later use. Weigh a certain amount of ferrous chloride and dissolve it in 2×10 -2 mol / L 3.0 generation PAMAM solution, made into iron salt solution, the iron concentration in the solution is 10×10 - 2 mol / L; Measure 200ml of the above solution and immerse it in 40g of the above-mentioned treated carrier, stir for 60min, then add 330ml of 0.2mol / l potassium borohydride solution dropwise, continue stirring for 80min, centrifuge, and dry at 40℃ to obtain the catalyst C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com