Method for manufacturing near-stoichiometry PPLN all-optical wavelength converter low in Mg doping

A near-stoichiometric ratio, wavelength converter technology, applied in the field of optical communications, can solve the problems of no anti-photorefractive characteristics, low conversion efficiency, small frequency multiplication nonlinear coefficient, etc., and achieve good anti-photorefractive characteristics , reduce the cost of raw materials, improve the effect of device integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

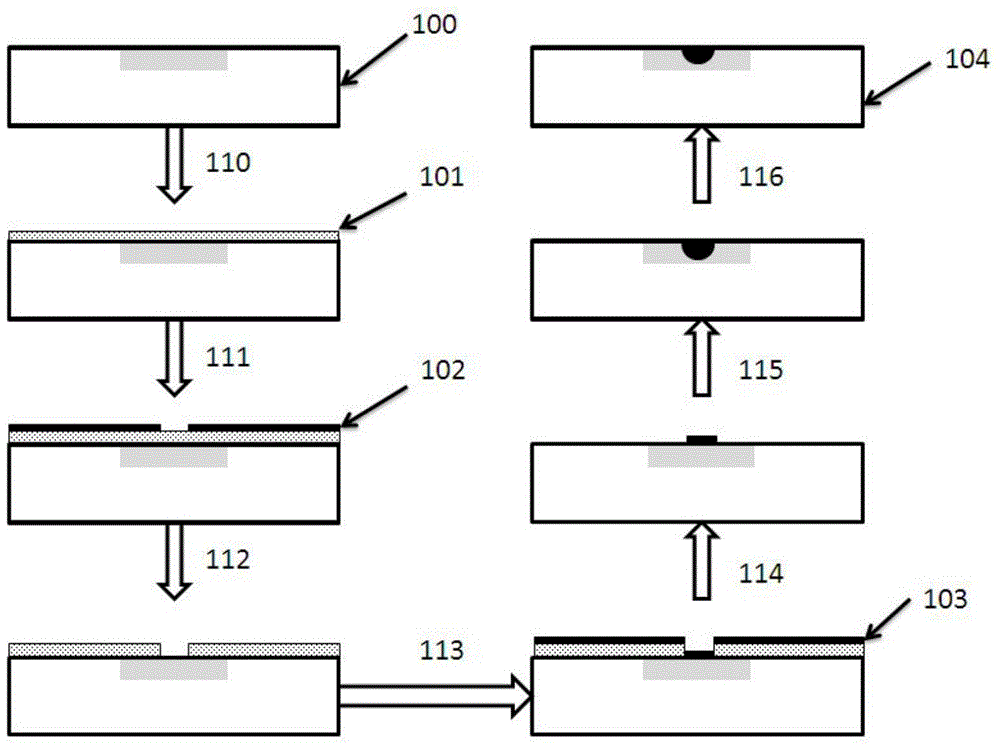

[0030] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. If there are exemplary contents in these embodiments, they should not be construed as limiting the present invention.

[0031] Step 1. Select a lithium niobate wafer of the same composition with a Z-cut thickness of 0.5mm-1mm. The upper and lower surfaces are parallel and both are optically polished. The normal direction of the upper and lower surfaces is the spontaneous polarization direction of the crystal;

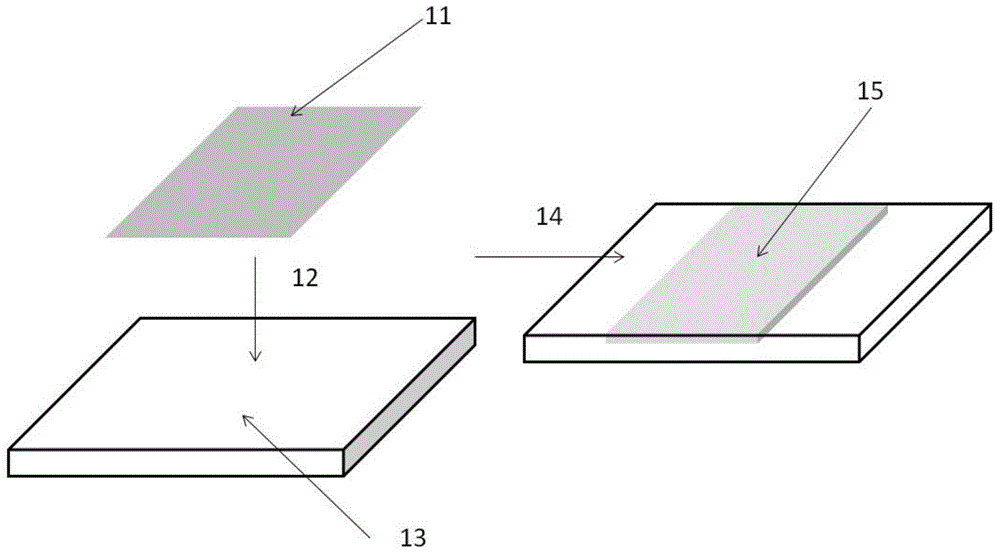

[0032] Step 2, Mg local doping: Coating a layer of MgO film on the surface of the wafer-Z, diffusing at a high temperature of 1050-1130°C for more than 1 hour to obtain lithium niobate crystals partially doped with magnesium, such as figure 2 shown;

[0033] Step 3. Manufacturing process of titanium-diffused lithium niobate optical waveguide: use photolithography process on the surface of the wafer-Z, plate titanium strips of 4-10 μm, us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com