Method for preparing natural polymer double-layer microcapsule through adoption of gas-liquid micro-channel

A technology of natural polymers and micro-channels, applied in the field of natural polymer double-layer microcapsules, can solve problems that have not attracted attention in research, and achieve the effects of simplifying the post-processing process, easy control, and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

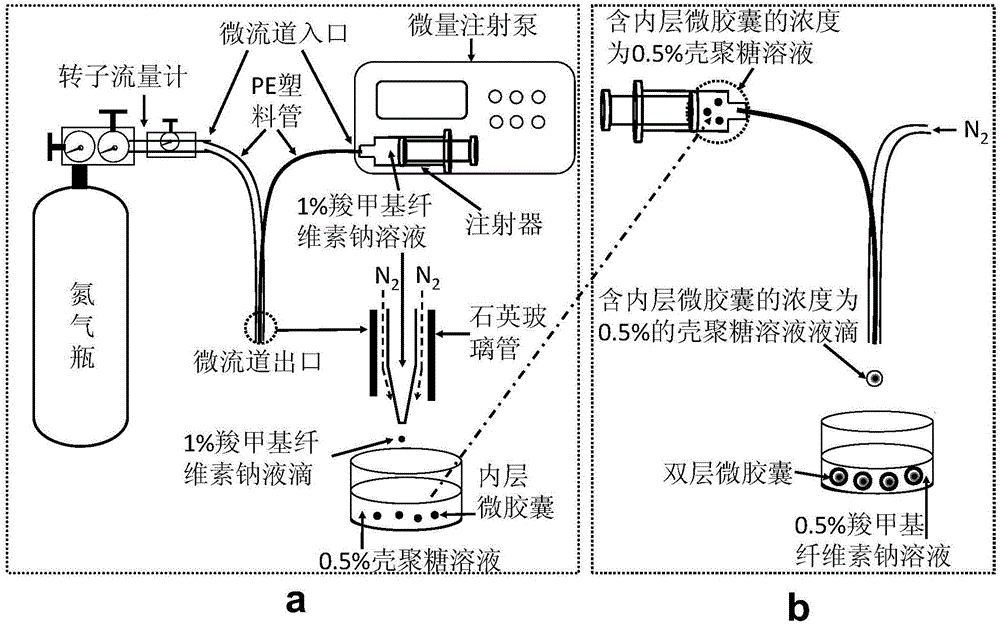

[0029] A method of chitosan / sodium carboxymethylcellulose double-layer microcapsules prepared by gas-liquid microchannel (that is, a method for preparing natural polymer double-layer microcapsules by gas-liquid microchannel), Including the following specific steps:

[0030] (1) Preparation of chitosan solution: get 1.0g of chitosan solid powder, add it to 180mL deionized water, stir for 30 minutes, then add hydrochloric acid with a concentration of 1.0mol / L to adjust the pH of the solution to 4.0, and stir for 3 hours Until the chitosan is fully dissolved, then add sodium hydroxide with a concentration of 1.0mol / L to adjust the pH of the solution to 5.0, then add an appropriate amount of deionized water to make the total volume of the solution 200mL, and then filter through a G3 sand core funnel to prepare the concentration 0.5% (w / v) chitosan solution.

[0031] (2) Preparation of sodium carboxymethyl cellulose solution: take 2.0 g of sodium carboxymethyl cellulose solid powd...

Embodiment 2

[0040] A method of chitosan / sodium carboxymethylcellulose double-layer microcapsules prepared by gas-liquid microchannels (i.e. a method of preparing natural polymer double-layer microcapsules by gas-liquid microchannels), Including the following specific steps:

[0041] (1) Prepare chitosan solution: get 0.8g chitosan solid powder, join in 180mL deionized water, stir for 30 minutes, then add the hydrochloric acid that concentration is 1.0mol / L to adjust the pH of the solution to be 4.0, and stir for 3 hours Until the chitosan is fully dissolved, then add sodium hydroxide with a concentration of 1.0mol / L to adjust the pH of the solution to 5.0, then add an appropriate amount of deionized water to make the total volume of the solution 200mL, and then filter through a G3 sand core funnel to prepare the concentration 0.4% (w / v) chitosan solution.

[0042] (2) Preparation of sodium carboxymethyl cellulose solution: take 1.6g of sodium carboxymethyl cellulose solid powder, add it ...

Embodiment 3

[0049] A method of chitosan / sodium carboxymethylcellulose double-layer microcapsules prepared by gas-liquid microchannels (i.e. a method of preparing natural polymer double-layer microcapsules by gas-liquid microchannels), Including the following specific steps:

[0050] (1) Prepare chitosan solution: get 1.2g chitosan solid powder, join in 180mL deionized water, stir for 30 minutes, then add the hydrochloric acid that concentration is 1.0mol / L to adjust the pH of the solution to be 4.0, and stir for 3 hours Until the chitosan is fully dissolved, then add sodium hydroxide with a concentration of 1.0mol / L to adjust the pH of the solution to 5.0, then add an appropriate amount of deionized water to make the total volume of the solution 200mL, and then filter through a G3 sand core funnel to prepare the concentration 0.6% (w / v) chitosan solution.

[0051] (2) Preparation of sodium carboxymethyl cellulose solution: Take 3.2g of sodium carboxymethyl cellulose solid powder, add it ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com