Preparing method of tubular TiO2/reduced graphene oxide composite

A composite material, graphene technology, applied in nanotechnology for materials and surface science, titanium dioxide, titanium oxide/hydroxide, etc., can solve the problems of cumbersome, repeated washing in the preparation process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

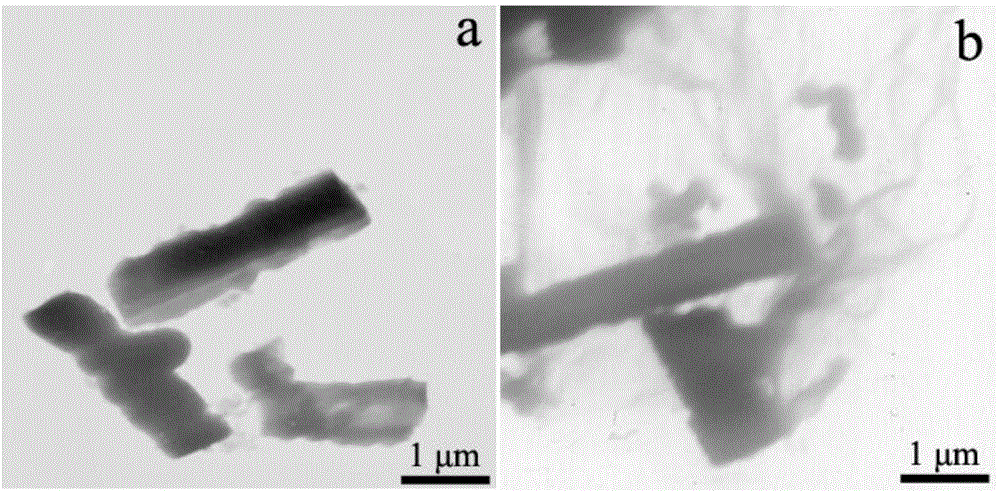

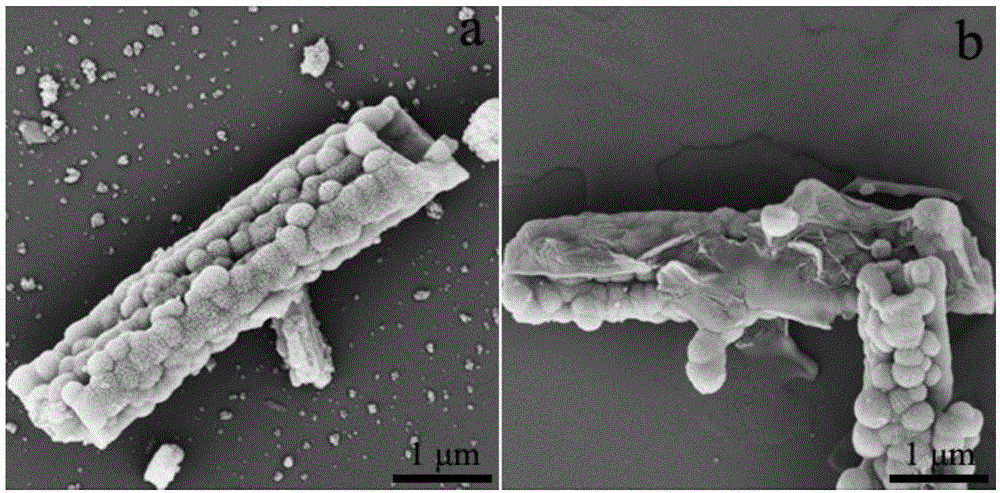

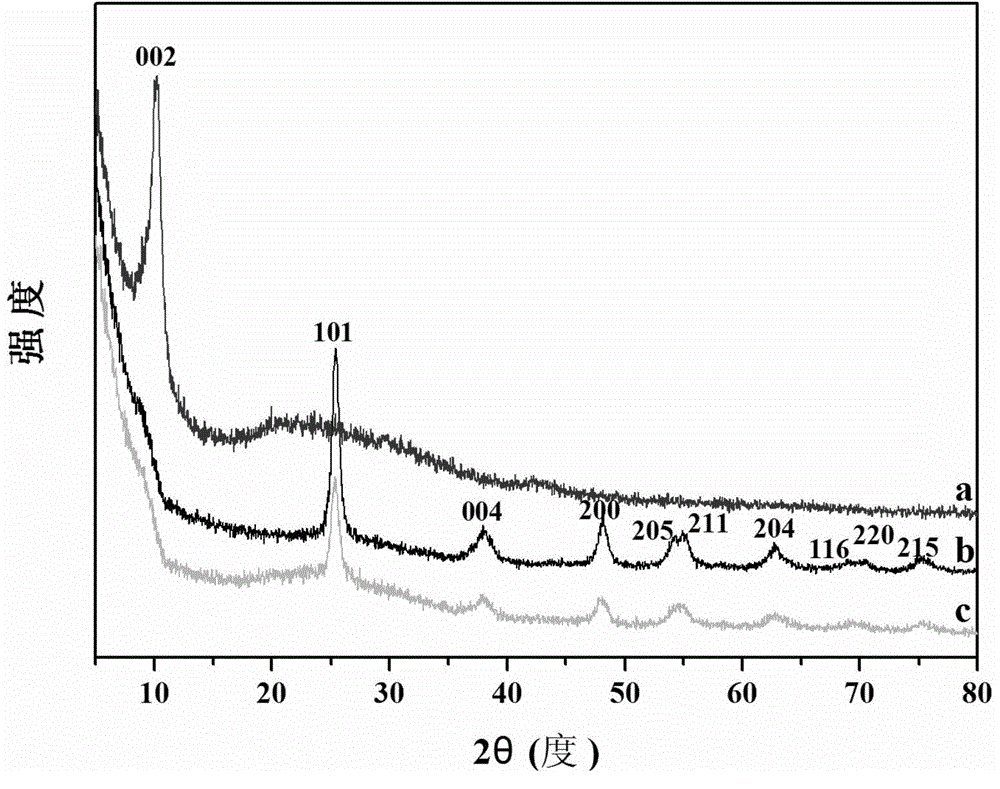

[0045] (1) Preparation of tubular TiO 2 Take 0.1000g P123 in a beaker, add 13ml ethanol, 6.5ml ethylene glycol, 6.5ml ether, stir at room temperature for 1h; add 0.5000g TiOSO 4 , stirred for 12 hours to obtain a suspension; transfer the suspension to a polytetrafluoroethylene-lined autoclave, tighten the autoclave and put it in an oven, keep it warm at 110°C for 24 hours, and heat the autoclave after hydrothermal treatment The kettle was naturally cooled to room temperature to obtain a precipitate; the obtained precipitate was centrifuged, washed with ethanol, centrifuged, dried, ground and calcined at 500°C for 4 hours to obtain a tubular TiO 2 .

[0046] (2) Prepare graphene oxide with 3g graphite powder, 30ml concentrated sulfuric acid, 3g K 2 S 2 o 8 Add to the beaker in turn, stir, ultrasonic for 5 minutes, put into a water bath, heat to 80°C and stir for 6h; slowly add distilled water to dilute to 1000ml, then filter with suction, dry at room temperature overnight...

Embodiment 2

[0050] (1) Preparation of tubular TiO 2 Take 0.1000g P123 in a beaker, add 13ml ethanol, 6.5ml ethylene glycol, 6.5ml ether, stir at room temperature for 1h; add 0.5000g TiOSO 4 , stirred for 12 hours to obtain a suspension; transfer the suspension to a polytetrafluoroethylene-lined autoclave, tighten the autoclave and put it in an oven, keep it warm at 110°C for 24 hours, and heat the autoclave after hydrothermal treatment The kettle was naturally cooled to room temperature to obtain a precipitate; the obtained precipitate was centrifuged, washed with ethanol, centrifuged, dried, ground and calcined at 500°C for 4 hours to obtain a tubular TiO 2 .

[0051] (2) Prepare graphene oxide with 3g graphite powder, 30ml concentrated sulfuric acid, 3g K 2 S 2 o 8 Add to the beaker in turn, stir, ultrasonic for 5 minutes, put into a water bath, heat to 80°C and stir for 6h; slowly add distilled water to dilute to 1000ml, then filter with suction, dry at room temperature overnight...

Embodiment 3

[0054] (1) Preparation of tubular TiO 2 Take 0.1000g P123 in a beaker, add 13ml ethanol, 6.5ml ethylene glycol, 6.5ml ether, stir at room temperature for 1h; add 0.5000g TiOSO 4 , stirred for 12 hours to obtain a suspension; transfer the suspension to a polytetrafluoroethylene-lined autoclave, tighten the autoclave and put it in an oven, keep it warm at 110°C for 24 hours, and heat the autoclave after hydrothermal treatment The kettle was naturally cooled to room temperature to obtain a precipitate; the obtained precipitate was centrifuged, washed with ethanol, centrifuged, dried, ground and calcined at 500°C for 4 hours to obtain a tubular TiO 2 .

[0055] (2) Prepare graphene oxide with 3g graphite powder, 30ml concentrated sulfuric acid, 3g K 2 S 2 o 8 Add to the beaker in turn, stir, ultrasonic for 5 minutes, put into a water bath, heat to 80°C and stir for 6h; slowly add distilled water to dilute to 1000ml, then filter with suction, dry at room temperature overnight...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com