Triphenylamine spirofluorene derivatives and uses thereof

A technology of fluorene spirotriphenylamine and its derivatives, which is applied in the field of organic photoelectric materials, can solve the problems of hindering wide application, low material stability, and low glass transition temperature, and achieve lower turn-on voltage, high-efficiency electroluminescence performance, The effect of device performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

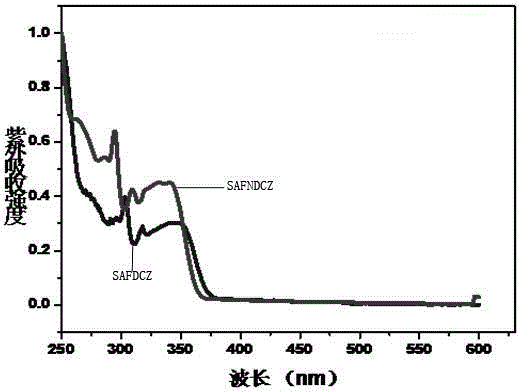

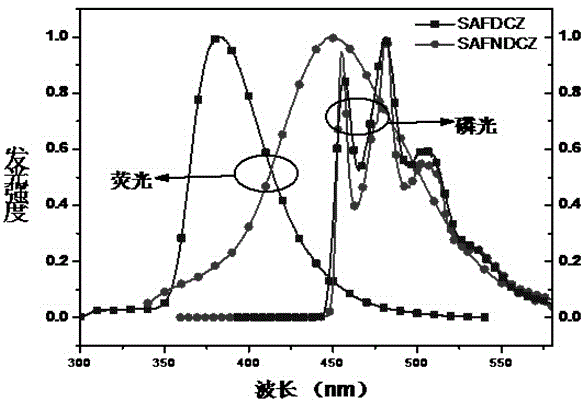

Method used

Image

Examples

Embodiment 1

[0043] Step 1: Dissolve 3.24 g of 2-bromotriphenylamine in 80 mL of tetrahydrofuran under argon protection, cool to -78 °C, slowly add 4.38 mL of n-butyllithium into the solution through a constant pressure dropping funnel, and react for 1 hour . Then 1.8 g of fluorenone was dissolved in 40 mL of tetrahydrofuran under the protection of argon and added dropwise to the reaction solution. After 1 hour of reaction at low temperature, it was gradually raised to room temperature. After 12 hours of reaction, 5 mL of water was added to the reaction, and then the solvent was spin-dried under reduced pressure. The solid was dissolved in 80 mL of dichloromethane, and the organic layer was washed three times with 50 mL of water. The organic layer was dried over anhydrous sodium sulfate and spin-dried. The solid obtained by spin-drying was dissolved in 45 mL glacial acetic acid and 10 mL nicotinic acid, refluxed for 4 hours, cooled to room temperature, then suction filtered and rinsed th...

Embodiment 2

[0047] Step 1: Same as Step 1 of Example 1.

[0048] Step 2: Same as Step 2 of Example 1.

[0049] Step 3: Add 1.11 g of dibromocyclo-closed triphenylamine and 0.68 g of α-N heterocarbazole into a 50 ml flask, add catalyst Pd 2 (dba) 3 92 mg, 80 ml of toluene, 29 mg of tri-tert-butylphosphonium tetrafluoroborate, 30 mg of sodium tert-butoxide, reflux under argon protection for 12 hours, extract with dichloromethane after cooling, dry the organic layer with anhydrous sodium sulfate and spin Dry, pass through the column with dichloromethane / petroleum ether = 1:1 (volume ratio), and spin dry to obtain 1.31 g of SAFNDCZ, with a yield of 88.5%.

Embodiment 3

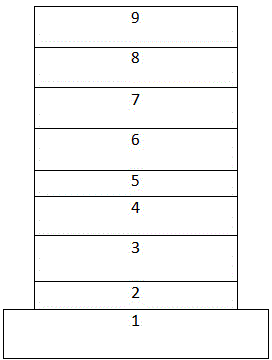

[0055] The compound SAFNDCZ of the present invention is used as the OLED device host material, FIrpic is a blue phosphorescent dye, and the device structure is:

[0056] ITO / HAT-CN(10nm) / TAPC(45nm) / SAFDCZ:FIrpic(20nm, 15vol% doping) / TmPyPB(40nm) / Liq(2nm) / Al(120nm).

[0057] The device preparation process is as follows: the ITO transparent conductive glass substrate is ultrasonically treated in a commercial cleaning agent, rinsed in deionized water, washed repeatedly with deionized water, acetone, and ethanol three times, and baked in a clean environment until the water is completely removed. Treat the ITO conductive glass with UV lamp and ozone. Place the treated ITO conductive glass in a vacuum chamber and evacuate to 3.0×10 -4 -4.0×10 -4 Pa, vacuum evaporated HAT-CN on ITO conductive glass as a hole injection layer (HIL), the evaporation rate is 0.25? / s, and the coating thickness is 10nm; vacuum evaporated TAPC on the hole injection layer as a hole Transport layer (HTL) a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com