Diethynylphenylaminosilane modified silicon-containing aryne resin and preparation method thereof

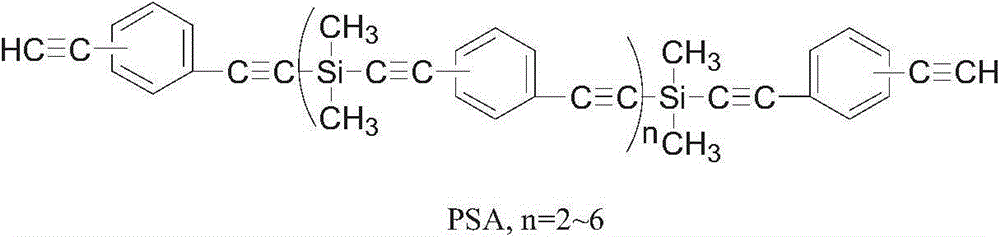

A technology of diethynylaniline silane and ethynyl aniline silane, which is applied in the field of silicon-containing aryne resin modified by diethynyl aniline silane and its preparation field, can solve the problem of high brittleness of cured products, low thermal performance and mechanical properties of composite materials Low-level problems, to achieve excellent mechanical properties and heat resistance, excellent heat resistance, and low melt viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

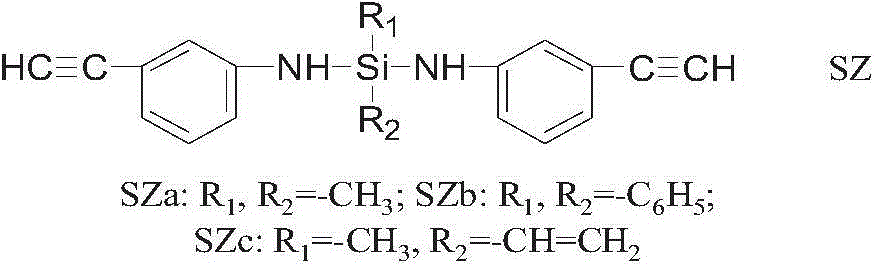

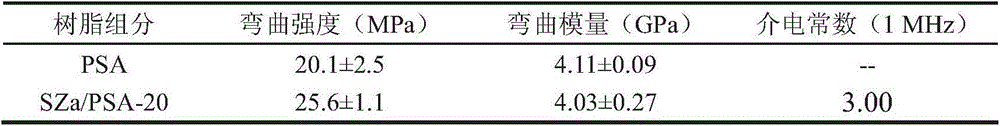

[0029] Dimethyl-bis(3-ethynylaniline)-silane modified silicon-containing aryne resin (SZa / PSA-20) and its preparation

[0030] 1. Synthesis of dimethyl-bis(3-ethynylaniline)-silane (SZa)

[0031] In a 250ml four-necked flask equipped with a stirrer, a reflux condenser, a thermometer and a vent, nitrogen protection was added, and 30ml of triethylamine (5.05g, 0.050mol) and 3-aminophenylacetylene (5.85g, 0.050mol) were added. Toluene solution, and it was cooled to -10°C, and a mixed solution of 30ml of toluene and dimethyldichlorosilane (3.25g, 0.025mol) was slowly added dropwise to it through a 50ml constant pressure funnel, and reacted for 1h after the dropwise addition was completed. Then heat up to 25°C to react for 4 hours. After the reaction, filter with suction, wash the filtrate with water 4 to 5 times, remove the water with anhydrous sodium sulfate, remove the solvent by rotary evaporation, and recrystallize to obtain white crystals with a melting point of 90.7°C. yl-b...

Embodiment 2

[0040] Dimethyl-bis(3-ethynylaniline)-silane modified silicon-containing aryne resin (SZa / PSA-40) and its preparation

[0041] Add SZa (40g) and PSA (60g) into a flask equipped with a stirrer, a thermometer and a reflux condenser, protect it with nitrogen, slowly heat up to 110°C and start stirring, and continue stirring for 0.5h after the reactants are completely melted. A reddish-brown modified silicon-containing aryne resin was obtained.

[0042] The reddish-brown resin has a viscosity of less than 0.4 Pa s in the range of 100-190°C, and begins to gel when the viscosity rises rapidly at 200°C; DSC test shows that the resin curing initial exothermic temperature is 209°C, and the peak exothermic temperature is 257°C. The exothermic end temperature is 296°C; the resin is cured in sections at 150°C / 2h, 170°C / 2h, and 210°C / 2h, and post-treated at 250°C / 4h to obtain a cured resin. In a nitrogen atmosphere, the thermal decomposition temperature of the cured product, that is, the ...

Embodiment 3

[0044] Diphenyl-bis(3-ethynylaniline)-silane modified silicon-containing aryne resin (SZb / PSA-10) and its preparation

[0045] 1. Synthesis of diphenyl-bis(3-ethynylaniline)-silane (SZb)

[0046] In a 250ml four-necked flask equipped with a stirrer, a reflux condenser, a thermometer and a vent, nitrogen protection was added, and 30ml of triethylamine (5.05g, 0.050mol) and 3-aminophenylacetylene (5.85g, 0.050mol) were added. Toluene solution, and it was cooled to -10°C, and a mixed solution of 30ml toluene and diphenyldichlorosilane (6.40g, 0.025mol) was slowly added dropwise to it through a 50ml constant pressure funnel, and reacted for 1h after the dropwise addition was completed , and then heated up to 70°C for 4 hours. After the reaction, filter with suction, wash the filtrate 4 to 5 times with water, remove the water with anhydrous sodium sulfate, remove the solvent by rotary evaporation, and precipitate a white solid with a melting point of 130.7°C, which is diphenyl yl-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com