Composite chitosan and cellulose membrane and preparation method and application thereof

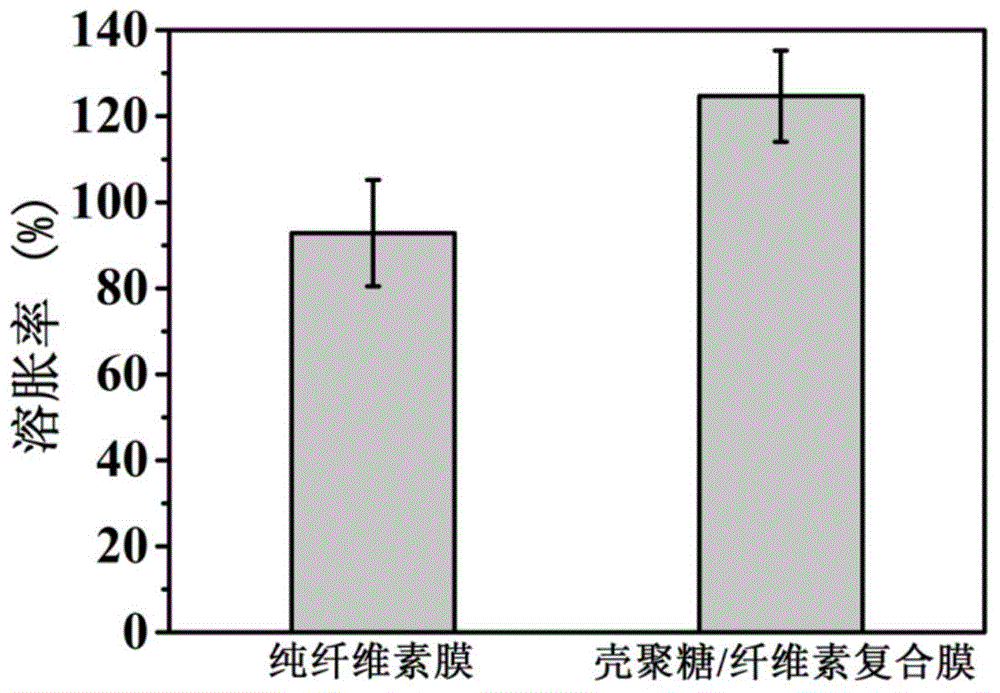

A technology of chitosan cellulose and regenerated cellulose film, applied in chitin polysaccharide coatings, coatings, hyaluronic acid coatings, etc., can solve the problem of poor compatibility and difficult preparation of cellulose/chitosan composite films , antibacterial performance is not significant and other issues, to achieve good biocompatibility and biodegradability, strong anti-infection and blood coagulation, and promote wound healing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

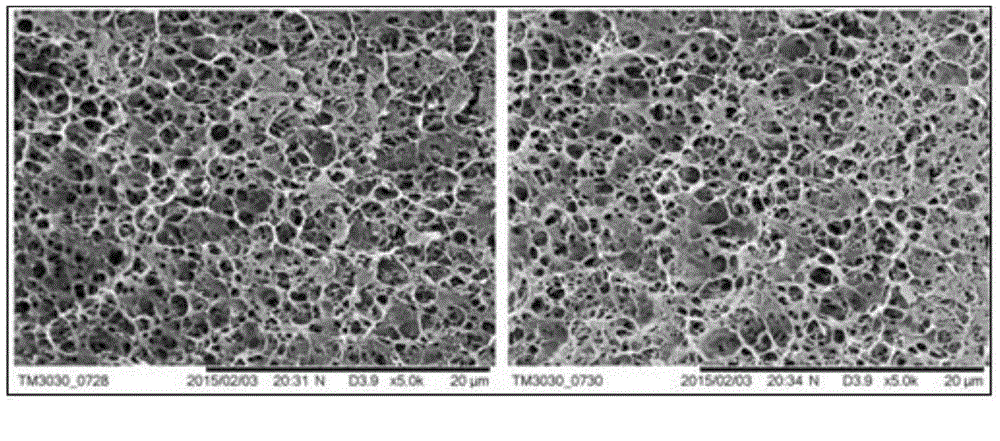

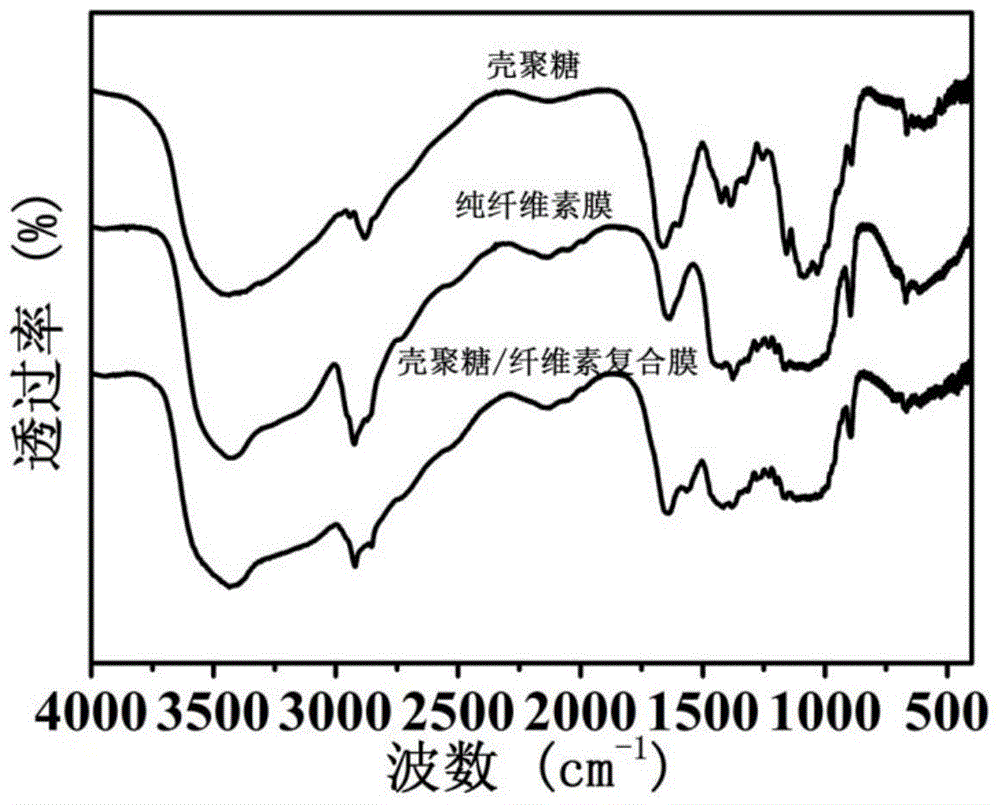

Embodiment 1

[0031] A kind of preparation method of chitosan cellulose composite film, concrete steps are as follows: with cellulose solvent (sodium hydroxide / urea aqueous solution, wherein the mass concentration of sodium hydroxide is 7%, the mass concentration of urea is 12%, all the other are Water) is pre-cooled to-12 ℃ as the cellulose solvent to dissolve the cellulose to obtain a cellulose solution with a cellulose mass concentration of 4%; the gained cellulose solution is defoamed, removed and cast scraping film, and in the coagulation bath (mass Concentration is 5% sulfuric acid solution) coagulation forming, after washing with distilled water, get the regenerated cellulose film; Under stirring condition, chitosan is dissolved in the acetic acid solution (the mass percentage of acetic acid is 90%), the preparation quality The mass percentage that chitosan accounts for is the chitosan solution of 10%; With the single needle (needle diameter is 0.9mm) as nozzle, and is connected with ...

Embodiment 2

[0036] A kind of preparation method of chitosan cellulose composite film, concrete steps are as follows: (sodium hydroxide / urea aqueous solution, wherein the mass concentration of sodium hydroxide is 10%, the mass concentration of urea is 2%, all the other are water) precooling Dissolving cellulose as a cellulose solvent at -5°C to obtain a cellulose solution with a cellulose mass concentration of 0.5%; the resulting cellulose solution is defoamed, removed and cast scraped film, and in a coagulation bath (mass concentration is 1%) Sulfuric acid solution) coagulated into shape, after washing with distilled water, regenerated cellulose film was obtained; under agitation, chitosan was dissolved in acetic acid solution (the mass percentage of acetic acid was 2%), and the prepared chitosan Accounting for mass percentage is 0.1% chitosan solution; with a single needle (needle diameter is 0.21mm) as the nozzle, and connected with electrostatic spraying device, inhale the above-mention...

Embodiment 3

[0039] A kind of preparation method of chitosan cellulose composite film, concrete steps are as follows: (sodium hydroxide / urea aqueous solution, wherein the mass concentration of sodium hydroxide is 7%, the mass concentration of urea is 12%, all the other are water) precooling Dissolving cellulose as a cellulose solvent at -12°C to obtain a cellulose solution with a cellulose mass concentration of 4%; the resulting cellulose solution is defoamed, removed and cast scraped film, and in a coagulation bath (mass concentration is 5%) Sulfuric acid solution) coagulated into shape, after washing with distilled water, regenerated cellulose film was obtained; under agitation, chitosan was dissolved in acetic acid solution (acetic acid accounted for 50% by mass), and the prepared chitosan Accounting for mass percent is 0.1% chitosan solution; with 2 needles (needle diameter is 0.21mm) as the nozzle, and connected with the electrostatic spray device, inhale the above-mentioned chitosan s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com