Formula and preparation method of polyester/epoxy resin powder coating

A technology of epoxy resin powder and powder coating, applied in the direction of powder coating, polyester coating, coating, etc., to achieve the effects of reducing curing time, good social benefits, and improving economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

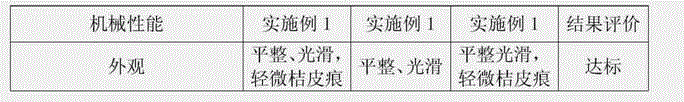

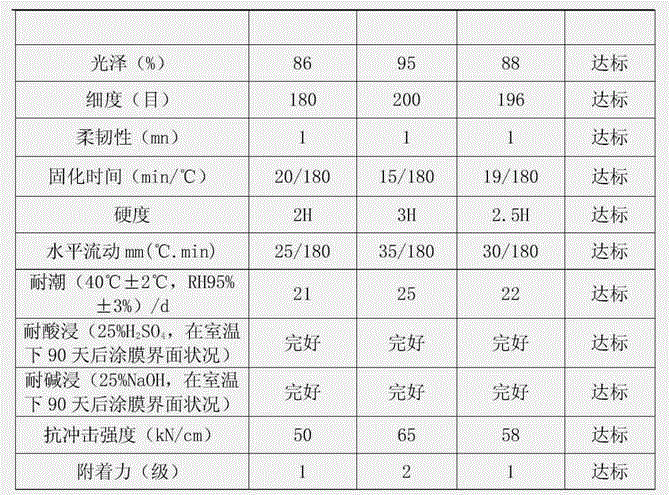

Examples

Embodiment 1

[0025] A kind of polyester / epoxy resin powder coating, the formula component of this powder coating is counted as: waste PET particle 723.6g, polyglycidyl methacrylate polymer 0.3mol, dibasic acid anhydride 0.9mol, binary acid anhydride Alcohol 1.71mol, catalyst 0.1%, high temperature resistant filler 10%, high temperature resistant pigment 3%, leveling agent 0.5%, curing agent 25%.

[0026] The relative molecular mass of the waste PET particles is 18000, and the melting point is 260°C.

[0027] The curing agent is aliphatic polyamine.

[0028] The dibasic acid anhydride is dibasic acid anhydride starch ester.

[0029] The high temperature resistant filler is mica powder.

[0030] The high temperature resistant pigment is titanium dioxide.

[0031] A kind of preparation method of polyester / epoxy resin powder coating, concrete preparation step comprises:

[0032] (1) Preparation of low-melting point oligomeric polyester: Alcoholyze the recovered waste PET particles with pol...

Embodiment 2

[0037] A kind of polyester / epoxy resin powder coating, the formula component of this powder coating is counted as: waste PET granule 735.5g, polyglycidyl methacrylate polymer 0.4mol, dibasic acid anhydride 1.00mol, binary acid anhydride Alcohol 1.75mol, catalyst 0.1%, high temperature resistant filler 18%, high temperature resistant pigment 6%, leveling agent 1.5%, curing agent 33%.

[0038] The relative molecular mass of the waste PET particles is 20000, and the melting point is 275°C.

[0039] The curing agent is aliphatic polyamine.

[0040] The dibasic acid anhydride is dibasic acid anhydride starch ester.

[0041] The high temperature resistant filler is mica powder.

[0042] The high temperature resistant pigment is titanium dioxide.

[0043] After preparing materials according to the above formula, its specific preparation method is the same as in Example 1.

Embodiment 3

[0045] A kind of polyester / epoxy resin powder coating, the formula component of this powder coating is counted as: waste PET granule 750.0g, polyglycidyl methacrylate polymer 0.5mol, dibasic acid anhydride 1.02mol, binary Alcohol 1.80mol, catalyst 0.1%, high temperature resistant filler 25%, high temperature resistant pigment 10%, leveling agent 2%, curing agent 40%.

[0046] The relative molecular mass of the waste PET particles is 23000, and the melting point is 305°C.

[0047] The curing agent is one of aliphatic polyamine, alicyclic polyamine, low molecular weight polyamide and modified aromatic amine.

[0048] The dibasic acid anhydride is dibasic acid anhydride starch ester.

[0049] The high temperature-resistant filler is any one of mica powder, silica powder and talc powder.

[0050] The high temperature-resistant pigment is any one of titanium dioxide, iron oxide red, and iron black.

[0051] After preparing materials according to the above formula, its specific p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com