Preparation method of bean flour without beany flavor and bitter taste

A bitter, beany-flavored technology, applied in the field of soybean powder preparation, can solve the problems of loss of heat-sensitive nutrients such as vitamins, single taste and color, protein denaturation, etc. With the effect of removing bitterness and astringency and short action time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Example 1: Using whole peas with skin as raw material to prepare whole pea powder that removes pea fishy smell and bitter taste

[0050] Whole dried peas with skin are crushed, humidified, physically modified by wet heat, dried, and finely crushed to obtain pea powder without pea fishy smell and bitter taste. The specific operation process is as follows:

[0051] (1) Pea removal: use non-genetically modified natural dry peas as raw materials, and use methods such as screening and cleaning to remove silt, floating soil and other sundries in whole peas with skins. Dried peas have a moisture content of 5-12%.

[0052] (2) Crushing: use a vertical grinder to crush 200 kg of dry peas into whole pea powders with a fineness of 80-100 mesh.

[0053] (3) Humidification: Add the whole pea powder obtained in the previous step into the mixing hopper of the electric mixer, and while stirring the whole pea powder, add drinking water to the whole pea powder by mechanically spraying ...

Embodiment 2

[0057] Embodiment 2: take peeled peas as raw material to prepare pea flour without pea fishy smell and bitter taste

[0058] (1) Crushing: use a hammer mill to crush 200 kg of peeled and dried peas to obtain pea powder with a fineness of 80-100 mesh. Dried peas have a moisture content of 5-12%.

[0059] (2) Humidity adjustment: Add the pea powder obtained in the previous step into the mixing hopper of the electric mixer, and while stirring the whole pea powder, add drinking water to the whole pea powder by mechanically spraying fine water droplets. The water temperature is 20°C- 30°C to make the added moisture evenly distributed in the pea flour. After humidification, the water content of the whole pea powder reaches 20%-30%. During the humidification process, the amount of water added to the pea powder=the water content of the humidified pea powder×the quality of the pea powder—the quality of the dry pea×the water content of the raw material (dry pea). The moisture content...

Embodiment 3

[0063] Embodiment 3: investigate the influence of wet heat treatment on fishy smell and bitter taste of peas.

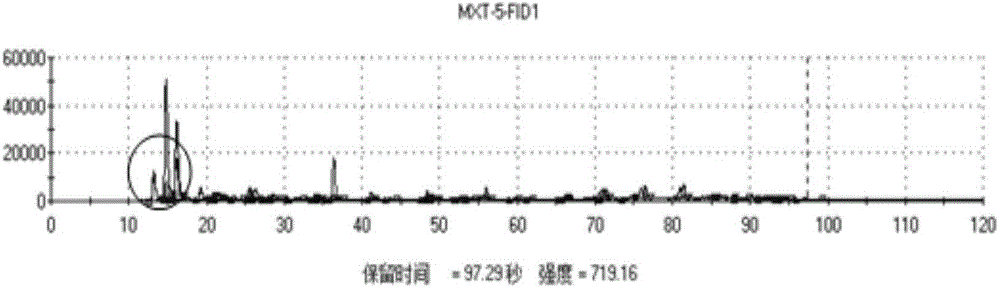

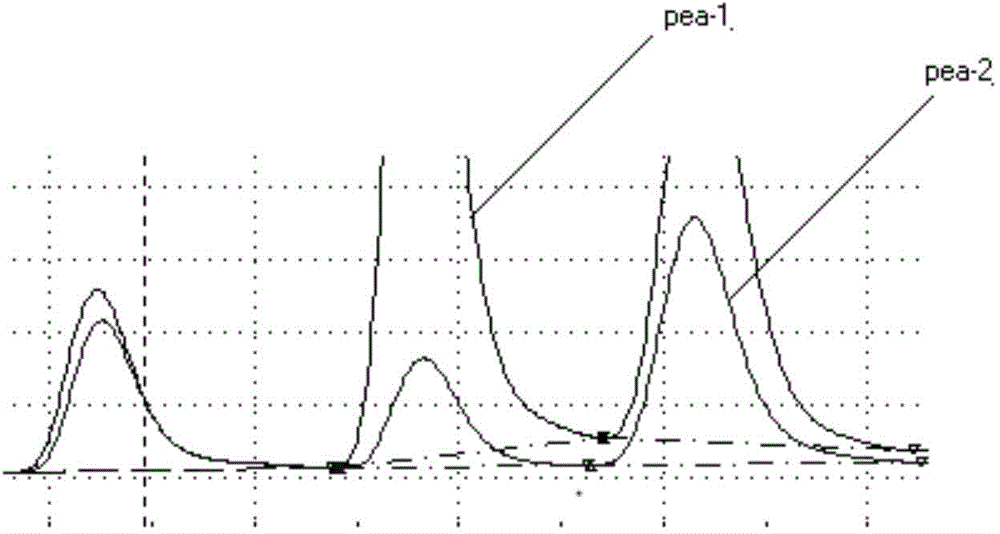

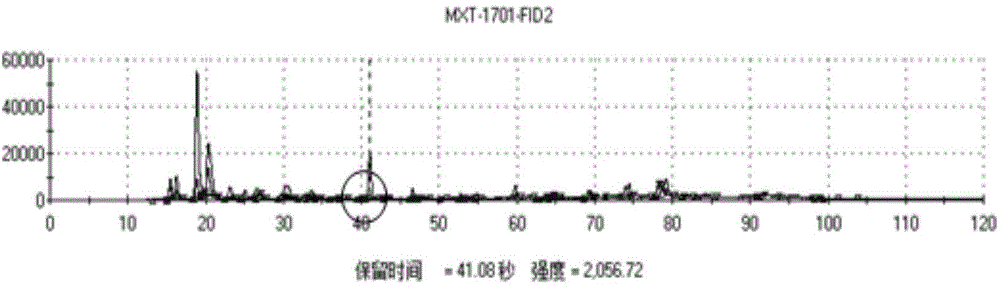

[0064] The odor analysis of the pea powder of the present invention (using raw pea powder as a control) was carried out by using an ultra-fast gas chromatography electronic nose (Flash E~Nose) from Alpha MOS Company. The Flash E~Nose system uses two chromatographic columns of different polarities, MXT~5 and MXT~1701 (length: 10m; column diameter: 180μm), MXT~5 is a non-polar chromatographic column, and MXT~1701 is a weak polar chromatographic column The column has a heating rate of 10°C / s, and the detectors are two hydrogen flame detectors. Alphasoft V12.46 was used for data processing.

[0065] The standard solution of n-alkane (nC6~nC16) was used for calibration, the retention time was converted into retention index, and then the compound was qualitatively analyzed using the AroChemBase database.

[0066] The experimental conditions of Heraclese electronic nose a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com