A kind of reaction device and method for preparing benzoic acid and benzaldehyde by direct oxidation of toluene

A reaction device and technology of benzaldehyde, applied in the field of chemical synthesis of benzoic acid and benzaldehyde, can solve the problems of prolonging the reaction time of toluene oxidation, low selectivity and yield of benzaldehyde, difficult controllability of toluene, etc., and achieve structural Simple, increased contact time, increased mass transfer effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

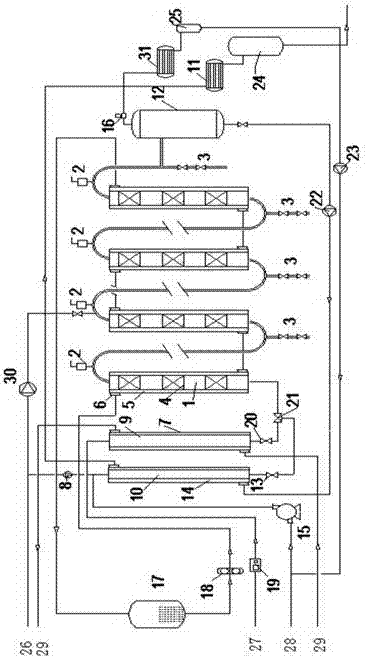

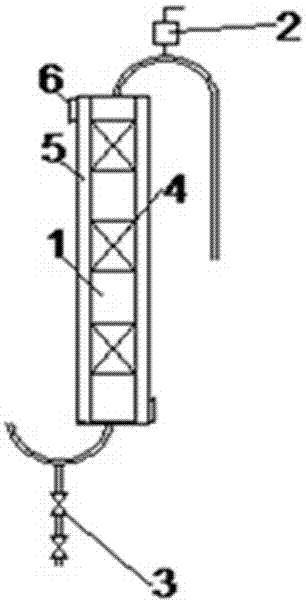

[0039] Embodiment 1 of the present invention provides a tubular reaction device and method for preparing benzoic acid and benzaldehyde by direct oxidation of toluene, for the preparation of benzoic acid and benzaldehyde, please refer to figure 2 As shown, the method includes:

[0040] (1) A tubular reaction device for preparing benzoic acid and benzaldehyde by direct oxidation of toluene, the device includes 15 tubular reaction sleeves, the height of the reaction sleeve is 15m, and the inner diameter of the reaction sleeve is 200mm.

[0041] (2) Start the material and gas delivery system, raw material preheating and high-temperature heat transfer oil circulation system: open the gas mass flow meter 19, and pass protective gas N into the system 2 To the system pressure is 0.7MPa; open the liquid phase material delivery pump 15, and transport the toluene reaction raw material solution 28 that is 0.01wt% benzaldehyde relative to the mass fraction of toluene in the toluene prehea...

Embodiment 2

[0049] Embodiment 2 of the present invention provides a tubular reaction device and method for the direct oxidation of toluene to prepare benzoic acid and benzaldehyde, for the preparation of benzoic acid and benzaldehyde, please refer to figure 2 As shown, the method includes:

[0050] (1) A tubular reaction device for preparing benzoic acid and benzaldehyde by direct oxidation of toluene, the device includes 18 tubular reaction sleeves, the height of the reaction sleeve is 11 m, and the inner diameter of the reaction sleeve is 180 mm.

[0051] (2) Start the material and gas delivery system, raw material preheating and high-temperature heat transfer oil circulation system: open the gas mass flow meter 19, and pass protective gas N into the system 2 To the system pressure is 0.7MPa; open the liquid phase material delivery pump 15, and transport the toluene reaction raw material solution 28 that is 0.02wt% benzaldehyde relative to the toluene mass fraction in the toluene prehe...

Embodiment 3

[0059] Embodiment 3 of the present invention provides a tubular reaction device and method for preparing benzoic acid and benzaldehyde by direct oxidation of toluene, for the preparation of benzoic acid and benzaldehyde, please refer to figure 2 As shown, the method includes:

[0060] (1) A tubular reaction device for preparing benzoic acid and benzaldehyde by direct oxidation of toluene, the device includes 13 tubular reaction sleeves, the height of the reaction sleeve is 12m, and the inner diameter of the reaction sleeve is 230mm.

[0061] (2) Start the material and gas delivery system, raw material preheating and high-temperature heat transfer oil circulation system: open the gas mass flow meter 19, and pass protective gas N into the system 2 To the system pressure is 0.7MPa; open the liquid phase material delivery pump 15, and transport the toluene reaction raw material solution 28 that is 0.03wt% benzaldehyde relative to the toluene mass fraction in the toluene preheatin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com